Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

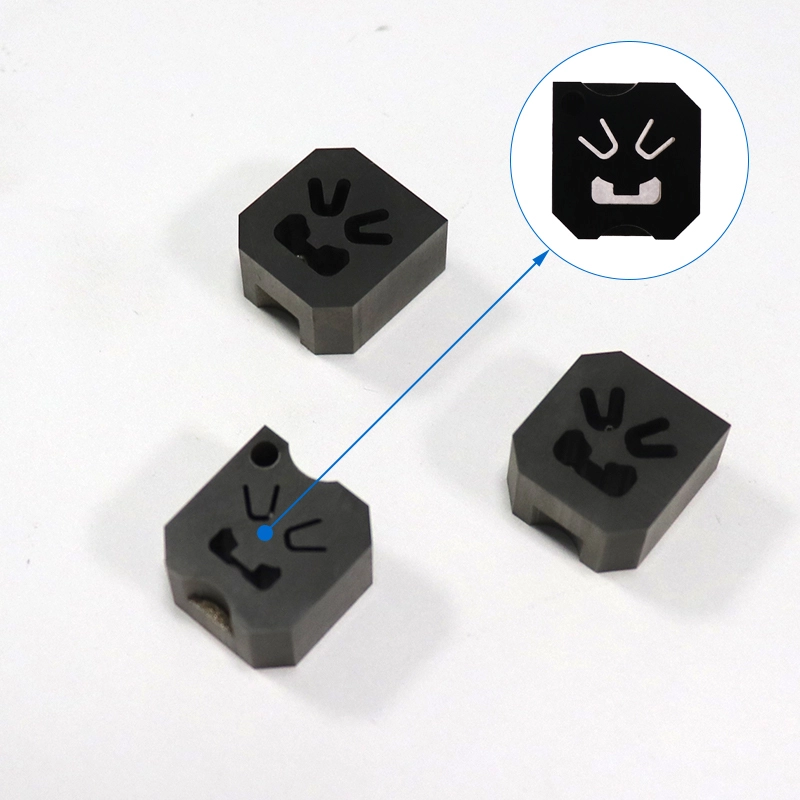

Precision Wire cutting parts

Precision Wire cutting parts is a part processing technology that uses high-speed electronic discharge to precisely cut parts by wire cutting machines.

The production process of Wire cutting parts is very rigorous and precise, and the highly sophisticated production and assembly process is designed to ensure the quality and precision of the parts to meet the needs of customers.

Production Process

The production process for precision wire cutting parts starts with a design or blueprint of the product. The designer creates a 3D CAD model of the product, which is then converted into G code. The G code is then sent to the Wire EDM machine, which converts it into a spark program.

Next, the raw material is clamped into the Wire EDM machine. The machine uses a wire as thin as 0.1mm to cut through the material. Electrical discharge occurs between the wire and the material, which vaporizes the material, creating a circular for precision wire cutting parts include:

◎ Stainless steel:

This is a popular material used in the aerospace and medical industries due to its excellent strength-to-weight ratio.

◎ Titanium:

A valuable metal used in industries like aerospace and automotive. Titanium is heat-resistant and has good corrosion resistance.

◎ Carbide:

A hard and tough material used in manufacturing cutting tools and dies.

◎ Aluminium:

Used in industries like aerospace and automotive due to its high strength-to-weight ratio.

◎ Copper:

High thermal conductivity makes copper ideal for use in electrical applications.

Applications

Wire EDM is widely used in various industries, including aerospace, automotive, medical, and electronics, among others. The parts produced through Wire EDM can be used in many applications, including:

◎ Aerospace:

Precision wire cutting parts are ideal for creating small and complex medical implants, including pacemakers and dental implants.

◎ Electronics Sector:

Aerospace companies use the Wire EDM process to create parts for their planes, including turbine blades and structural components.

◎ Automotive:

It is used to create engine parts, suspension systems, and brake components.

◎ Electronics:

The Wire EDM process can create small and intricate parts used in electronic devices like smartphones and computers.

Advantages

Wire EDM has several advantages over conventional machining processes, including:

◎ Precision:

Wire EDM is incredibly precise and can produce parts with tolerances as small as +/-0.0001 inches.

◎ No tool wear:

Because the Wire EDM process does not involve cutting tools, there is no tool wear or degrading of tool edges.

◎ No burrs:

Wire EDM does not produce burrs, which is helpful when producing small and intricate parts.

◎ Versatility:

Wire EDM can work with a wide range of materials, making it a versatile machining process.

Disadvantages

Despite its many advantages, Wire EDM has a few disadvantages, including:

◎ Slow:

Wire EDM is a slow machining process, and it can take a long time to produce a single part.

◎ Expensive:

The Wire EDM machines are expensive, and the process can be costly, especially for small production runs.

◎ Limited material thickness:

Wire EDM is limited to material thicknesses of around 12 inches, which can be a drawback for certain applications.

FAQ