Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

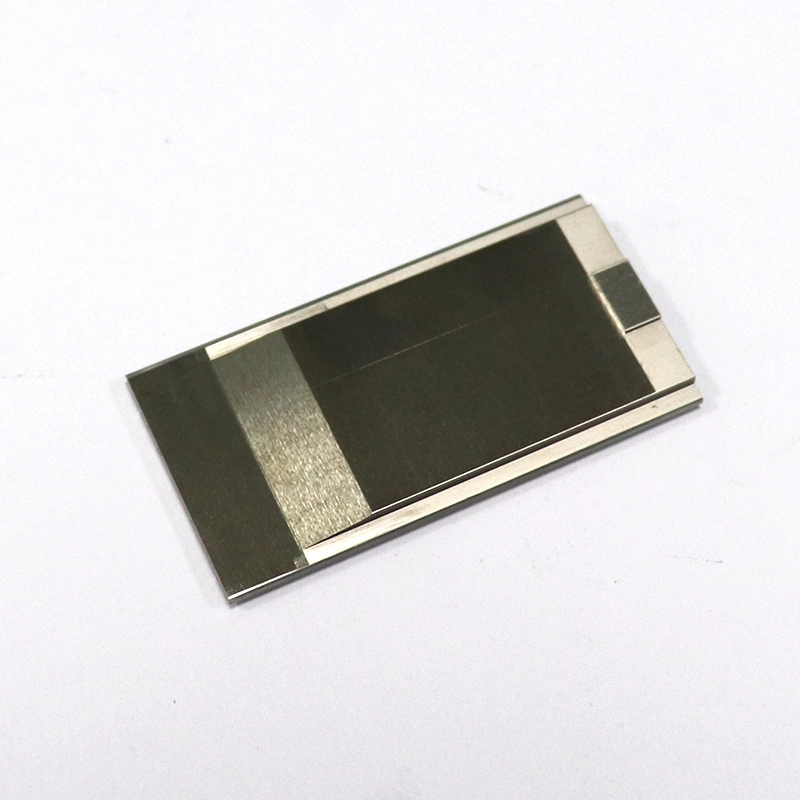

Precision Optical profile grinding parts丨RuiXing CNC

The Optical Profile Grinding process involves the use of a specialized optical system that projects a magnified image of the workpiece onto a screen. This projection allows the operator to precisely position and control the grinding process.

By comparing the projected image with the desired specifications, the operator can make accurate adjustments to achieve the desired surface finish and dimensional accuracy.

Product Applications

As the manufacturing industry continues to evolve, businesses are always looking for ways to improve precision and efficiency. Optical profile grinding is a machining process that plays a vital role in meeting manufacturing standards. At the heart of optical profile grinding is the set of parts that allow this technology to function at its maximum potential. For businesses looking to take advantage of optical profile grinding, it is important to understand the intricate details of these parts.

Precision Optical profile grinding parts are designed to enable precise machining of complex shapes such as angles, curves, and various contours. Specifically, these parts are essential in allowing the machine to produce precise profiles on a wide range of materials including metals, plastics, and ceramics. The parts are designed using high-quality materials such as tungsten carbide, which allows for precision machining over long periods. The tungsten carbide material also helps to reduce maintenance costs, ultimately saving money for the business.

The profile grinding parts include a cutting tool, a chuck, and a grinding wheel. The cutting tool is responsible for guiding the grinding wheel and cutting the material to the desired profile shape. The chuck is the device that holds the workpiece in place while allowing for rotational movement, while the grinding wheel is the abrasive tool that removes excess material from the workpiece.

Technology Several Advantages

◎ Fast and accurate results:

Optical profile grinding offers an efficient and accurate method to produce complex shapes. With its ability to work with a wide range of materials, various shapes and contours can be machined to precise specifications.

◎ Minimal material wastage:

The use of high-quality cutting tools and abrasive wheels results in minimal material wastage. This is important for businesses as it saves money by reducing the amount of waste produced.

◎ Reduced manufacturing costs:

Optical profile grinding provides businesses with the ability to manufacture intricate parts more efficiently, reducing the amount of time and energy required to complete a project. This, in turn, reduces the overall production cost.

◎ A wide range of applications:

The process of optical profile grinding can be used in a wide range of applications, including aerospace, medical, and automotive industries. This also makes it a versatile option for businesses looking to expand their product lines.

Application

◎ Automotive Industry:

In the automotive industry, Precision Optical Profile Grinding Parts find extensive use in the manufacturing of various components. These parts are employed in the production of engine parts, transmission components, gears, camshafts, and crankshafts. The precise profiling and grinding capabilities of our components ensure the desired surface finish, dimensional accuracy, and geometrical integrity, contributing to the overall performance and reliability of automotive systems.

◎ Aerospace Industry:

The aerospace industry demands utmost precision and high-quality components. They play a crucial role in the production of aerospace components such as turbine blades, compressor parts, fuel system components, and landing gear parts. The ability to achieve intricate profiles and precise grinding results ensures the optimal performance and safety of aerospace systems.

◎ Medical Devices:

In the medical field, precision is of utmost importance. They are used in the manufacturing of medical devices such as surgical instruments, orthopedic implants, dental tools, and diagnostic equipment. The exceptional precision and accuracy of our components contribute to the effectiveness and reliability of medical procedures, ensuring patient safety and positive outcomes.

◎ Precision Engineering:

They find applications in various precision engineering industries. These include the production of molds, dies, tooling components, and precision machinery parts. The ability to achieve complex profiles and precise grinding results allows for the creation of intricate and high-quality components used in industries such as electronics, telecommunications, and consumer goods.

◎ Tool and Die Making:

Tool and die makers rely on them to produce high-precision tools and dies. These components are used in the manufacturing of cutting tools, molds, and dies for metal stamping, injection molding, and other industrial processes. The accuracy and durability of our parts contribute to the longevity and performance of the tooling, resulting in efficient and reliable production processes.

◎ Research and Development:

Precision Optical Profile Grinding Parts are also utilized in research and development settings. These parts are employed in prototyping, testing, and experimentation processes, where precise profiling and grinding are required to validate new designs and concepts. The versatility and customization options offered by our components enable researchers and engineers to explore innovative solutions and optimize their designs.

FAQ