Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

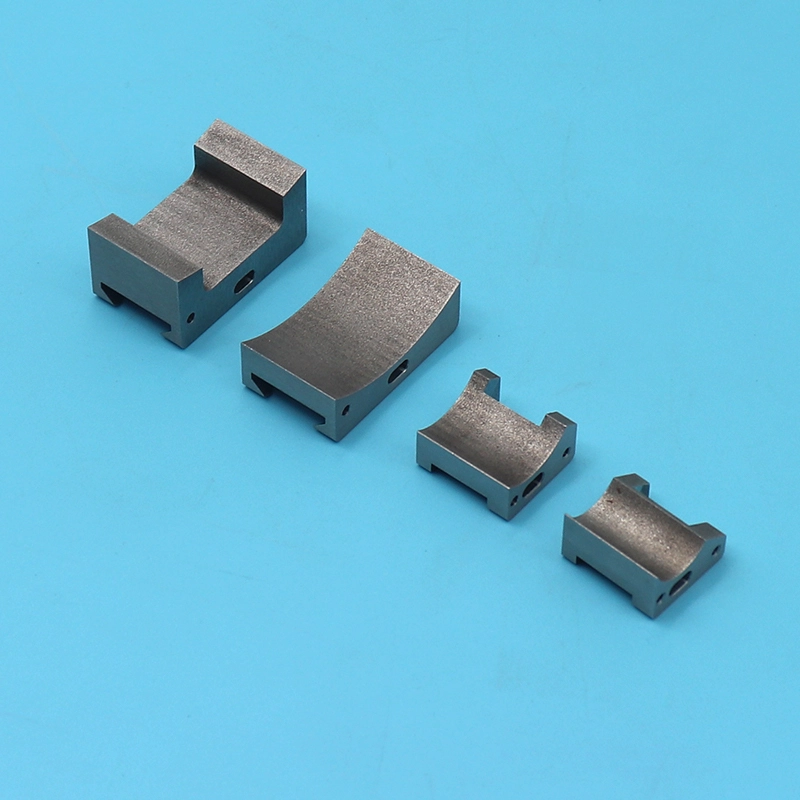

Custom Wire EDM 17-4PH Stainless Steel service

As a OEM CNC machining facility, we provide custom Wire EDM 17-4PH stainless steel service, we specialize in delivering precision-engineered solutions tailored to the specific needs of B2B manufacturing.

1. Precision Wire EDM:

Wire EDM technology enables precise cuts, intricate shapes, and tight tolerances, ensuring the manufacturing of high-performance components.

2. Customization for B2B Needs:

We understand the unique requirements of B2B manufacturing. Our team collaborates with clients to provide tailored solutions, meeting specific design and functionality criteria.

3. Quality Assurance:

Committed to delivering excellence, our quality assurance processes guarantee the reliability and durability of components manufactured through our Custom Wire EDM service.

Material characteristics

1. Chemical Composition:

- 17-4PH Stainless Steel is a precipitation-hardening alloy comprising 15-17% chromium, 3-5% nickel, 3-5% copper, and 0.15-0.45% niobium.

2. Mechanical Properties:

- Tensile Strength: 100 ksi (690 MPa)

- Yield Strength: 90 ksi (620 MPa)

- Elongation: 14%

- Hardness: HRC 36

3. Corrosion Resistance:

- Exhibits excellent corrosion resistance, suitable for applications in harsh environments.

4. Heat Treatment:

- Heat-treatable for high strength and hardness.

5. Machinability:

- Demonstrates good machinability in the annealed condition.

Advantages:

1. High Strength:

- 17-4PH Stainless Steel offers high tensile and yield strength, making it ideal for applications requiring robust mechanical properties.

2. Corrosion Resistance:

- Exceptional corrosion resistance ensures durability in corrosive environments.

3. Heat Treatability:

- Heat-treatable to achieve desired hardness, providing versatility in material properties.

4. Versatility in Applications:

- Suitable for a wide range of applications, from aerospace components to industrial machinery.

Challenges:

1. Machining Complexity:

- High-strength characteristics can pose challenges during machining operations, requiring specialized techniques.

2. Tool Wear:

- Due to its hardness, tool wear may occur faster, necessitating careful tool selection and monitoring.

3. Cost Considerations:

- While versatile, the cost of 17-4PH Stainless Steel may be higher than other materials, impacting overall project costs.

Application

1. Aerospace Components:

Precision is paramount in aerospace manufacturing. Our custom Wire EDM 17-4PH stainless steel service excels in producing intricate components for aircraft and spacecraft, utilizing 17-4PH stainless steel's corrosion resistance and mechanical strength.

2. Medical Instruments:

In the medical sector, where precision and reliability are critical, our service contributes to the production of surgical instruments and medical devices. The corrosion-resistant nature of 17-4PH stainless steel ensures longevity and compliance with stringent medical standards.

3. Oil and Gas Equipment:

Components used in the demanding oil and gas industry require materials with high corrosion resistance. Our service caters to the production of durable and reliable parts for drilling equipment, valves, and other critical applications.

4. Automotive Manufacturing:

In the automotive sector, our Custom Wire EDM service plays a key role in producing components with intricate geometries and precise specifications. 17-4PH stainless steel's mechanical properties make it suitable for various automotive applications.

5. Tool and Die Manufacturing:

Manufacturers of tools and dies benefit from the precision of our service, producing intricate molds and dies with high durability. The corrosion-resistant properties of 17-4PH stainless steel ensure longevity in demanding tooling applications.

6. Industrial Machinery Components:

From gears to intricate machine components, our service contributes to the manufacturing of industrial machinery parts. The adaptability of 17-4PH stainless steel makes it a preferred material for various industrial applications.

7. Custom OEM Solutions:

Beyond specific industries, our custom Wire EDM 17-4PH stainless steel service offers versatile solutions for OEM applications. Collaborating closely with B2B clients, we provide customized components tailored to their unique design and functional requirements.

FAQ