Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

Custom CNC milling plastic POM parts

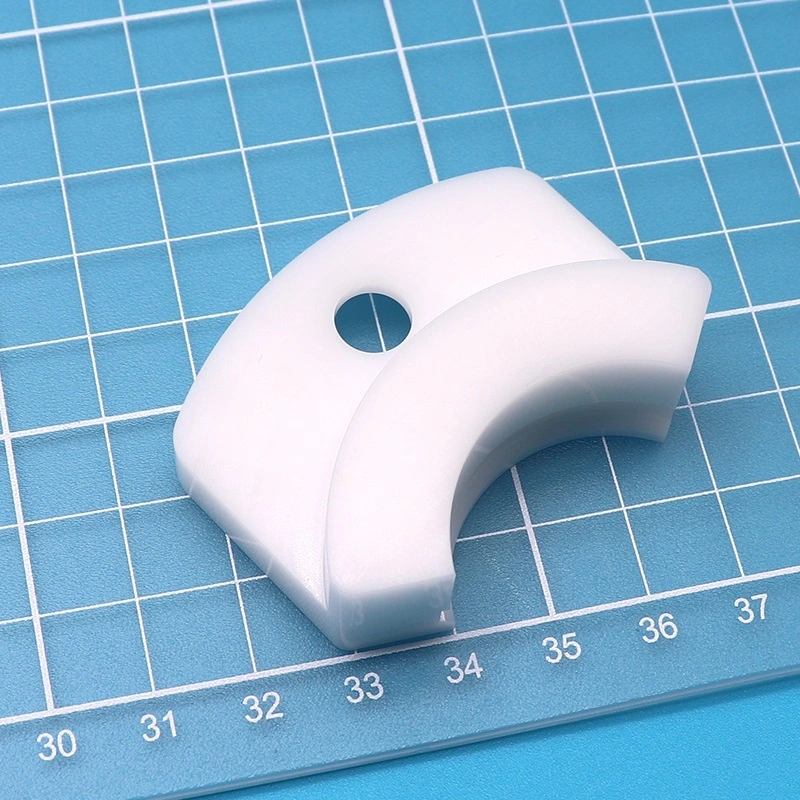

Our specialized CNC machining facility offers precision-engineered solutions for custom Plastic POM parts through CNC milling. With a focus on meticulous craftsmanship, we deliver tailored components to meet your exact specifications.

Material Expertise – Plastic POM:

Plastic POM, also known as Delrin or Acetal, is a versatile engineering plastic renowned for its durability and low friction. Our machining experts are adept at optimizing the CNC milling process to achieve optimal results with this material.

Applications of Plastic POM Parts:

Plastic POM parts find extensive applications across various industries, including automotive, electronics, and consumer goods. Its exceptional properties make it suitable for components requiring strength, stability, and resistance to wear.

Customization for Your Needs:

Understanding the unique requirements of each project, we offer customized solutions tailored to your specifications. Whether it's intricate designs or specific dimensions, our CNC milling services ensure that your Plastic POM parts meet your exact needs.

Characteristic

1. Density and Weight:

POM plastic, also known as polyoxymethylene or acetal, possesses a density of approximately 1.42 g/cm³. Its relatively low weight makes it suitable for applications where lightweight components are crucial.

2. Mechanical Properties:

With a tensile strength of around 63 MPa and a flexural modulus of approximately 2,700 MPa, POM exhibits excellent mechanical properties. This makes it resilient under various loads, contributing to its effectiveness in engineering applications.

3. Friction and Wear Resistance:

One of the standout features of POM is its inherent low friction coefficient, which is around 0.2. Additionally, it demonstrates excellent wear resistance, making it suitable for components subjected to repetitive motion and contact.

4. Temperature Stability:

POM plastic exhibits stability over a wide temperature range. Its melting point is approximately 175°C, and it retains its mechanical properties at elevated temperatures, allowing for applications in diverse environments.

5. Chemical Resistance:

POM is resistant to a variety of chemicals, including fuels, solvents, and oils. This chemical resistance makes it a preferred choice for components that may come into contact with different substances during their lifespan.

Advantages:

a. Dimensional Stability:

POM maintains precise dimensions even under varying temperature and humidity conditions, ensuring the longevity and reliability of custom CNC-milled parts.

b. Low Moisture Absorption:

The material exhibits low moisture absorption, reducing the impact of environmental factors on its properties. This feature is particularly beneficial in applications requiring consistent performance.

c. Machinability:

POM is highly machinable, allowing for intricate designs and precision during the CNC milling process. Its machinability contributes to the production of complex custom parts.

Disadvantages:

a. Susceptibility to UV Degradation:

POM may undergo UV degradation over extended exposure to sunlight. Consideration should be given to applications where prolonged outdoor exposure is a factor.

b. Limited Color Options:

While available in standard colors such as white, black, and natural, POM has limitations in terms of vibrant color options compared to some other plastics.

c. Not Suitable for High-Load Bearings:

Despite its excellent mechanical properties, POM may not be the ideal choice for high-load bearing applications where other materials like metals might be more appropriate.

Alternatives:

Several materials can serve as alternatives to POM based on specific application requirements. Common alternatives include nylon (PA), polyethylene (PE), and polyurethane (PU). The selection depends on factors such as mechanical demands, chemical exposure, and environmental conditions.

Application

1. Automotive Industry: Steering Components

Precision is paramount in the automotive sector, and custom CNC-milled Plastic POM parts find a niche in steering components. From gear guides to bushings, the durability and low-friction properties of Plastic POM contribute to the reliable performance of steering systems.

2. Electronics Sector: Insulating Components

In electronic devices where insulation is crucial, Plastic POM parts shine. Custom-milled insulating components, such as electrical connectors and housing, benefit from the material's dielectric strength and resistance to moisture, ensuring optimal functionality.

3. Consumer Goods: Gears for Appliances

Within consumer goods, Plastic POM gears play a pivotal role in appliances like printers and copiers. The material's wear resistance and dimensional stability make it an ideal choice for gears, ensuring smooth and reliable operation over extended usage.

4. Aerospace Industry: Structural Components

Aerospace demands components that can withstand extreme conditions. Custom CNC-milled Plastic POM parts contribute to the production of lightweight structural components, offering a balance between strength and weight in aerospace applications.

5. Medical Devices: Surgical Instrument Parts

In the medical field, precision is non-negotiable. Plastic POM's biocompatibility and resistance to sterilization processes make it suitable for crafting surgical instrument components, ensuring the highest standards of safety and reliability.

FAQ