Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

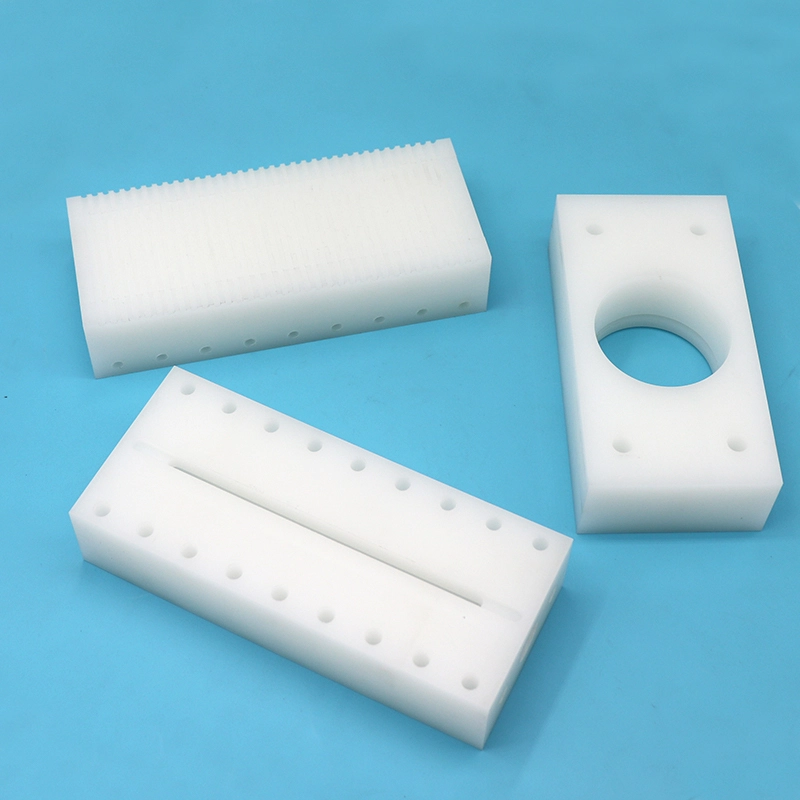

CNC Precision Milled PP Plastic Parts

Polypropylene, known for its excellent mechanical properties, makes our parts lightweight yet robust. It offers exceptional resistance to chemicals, moisture, and impact, making it suitable for a wide range of applications.

DESCRIPTION

CNC Precision Milled PP Plastic Parts are high-quality plastic components produced using Computer Numerical Control (CNC) technology. These parts are manufactured with precise milling techniques to ensure excellent accuracy and consistency, delivering reliable performance in various industries.

Features

1. Density:

Polypropylene (PP) plastic has a density ranging from 0.895 to 0.92 g/cm³, making it a lightweight material that offers ease of handling and transportation.

2. Melting Point:

PP plastic has a relatively low melting point, typically around 130 to 171°C (266 to 340°F). This property allows for easy processing and molding.

3. Tensile Strength:

PP plastic exhibits good tensile strength, with values ranging from 30 to 45 MPa (4,350 to 6,525 psi). It provides structural integrity and resistance to external forces.

4. Flexural Strength:

The flexural strength of PP plastic is approximately 30 to 40 MPa (4,350 to 5,800 psi), indicating its ability to withstand bending without breaking.

5. Impact Strength:

PP plastic possesses excellent impact strength, with values ranging from 20 to 40 kJ/m². It can withstand sudden impacts and shocks without significant damage.

6. Chemical Resistance:

PP plastic demonstrates high resistance to a wide range of chemicals, including acids, alkalis, and solvents. This property makes it suitable for applications requiring exposure to various substances.

7. Heat Resistance:

PP plastic exhibits good heat resistance, maintaining its properties at temperatures ranging from -10 to 100°C (14 to 212°F). It can withstand moderate heat without deformation or degradation.

8. Electrical Insulation:

PP plastic has excellent electrical insulation properties, making it suitable for applications in the electronics and electrical industries.

Advantages of PP Plastic:

1. Lightweight:

PP plastic's low density makes it a lightweight material, reducing overall product weight and enhancing ease of handling.

2. Cost-effective:

PP plastic is relatively inexpensive compared to other engineering plastics, offering cost savings in manufacturing and production.

3. Chemical Resistance:

PP plastic's resistance to chemicals allows it to withstand exposure to corrosive substances, ensuring durability and longevity.

4. Versatility:

PP plastic can be easily molded, extruded, and formed into various shapes, making it highly versatile for different applications.

5. Recyclability:

PP plastic is recyclable, contributing to environmental sustainability and reducing waste.

Disadvantages of PP Plastic:

1. UV Sensitivity:

PP plastic is sensitive to ultraviolet (UV) radiation, which can cause degradation and discoloration over time when exposed to sunlight.

2. Lower Temperature Resistance:

While PP plastic is heat resistant to moderate temperatures, it has lower resistance to high temperatures compared to some other engineering plastics.

3. Limited Rigidity:

PP plastic may have lower rigidity compared to certain materials, which can impact its suitability for applications requiring high stiffness.

4. Poor Adhesion:

PP plastic has poor adhesion properties, making it challenging to bond or adhere to other materials without proper surface treatment or the use of specialized adhesives.

Applications

1. Automotive Industry:

CNC precision milled PP plastic parts are widely utilized in the automotive sector. They are employed in various applications such as interior and exterior trim components, dashboard panels, door handles, ventilation systems, and engine compartments. The lightweight nature of PP plastic parts contributes to fuel efficiency while maintaining durability and aesthetic appeal.

2. Electronics and Electrical Appliances:

In the electronics industry, they are commonly found in devices such as smartphones, laptops, tablets, and televisions. These parts are used for casings, connectors, buttons, and structural components due to their electrical insulation properties, impact resistance, and dimensional stability.

3. Medical Equipment:

PP plastic parts are extensively used in the medical field due to their biocompatibility and sterilization capabilities. They are utilized in medical devices, diagnostic equipment, laboratory instruments, and surgical tools. They offer excellent resistance to chemicals, ensuring the safety and reliability of medical applications.

4. Consumer Goods:

They play a significant role in various consumer goods. They are employed in the manufacturing of household appliances, toys, sporting equipment, and furniture. These parts offer versatility in design, color options, and surface finishes, making them ideal for creating aesthetically pleasing and functional products.

5. Industrial Applications:

In industrial settings, CNC precision milled PP plastic parts are used in machinery, equipment, and infrastructure. They serve as components in conveyor systems, pumps, valves, and seals. The corrosion resistance, low friction coefficient, and high strength of PP plastic parts make them suitable for demanding industrial environments.

FAQ