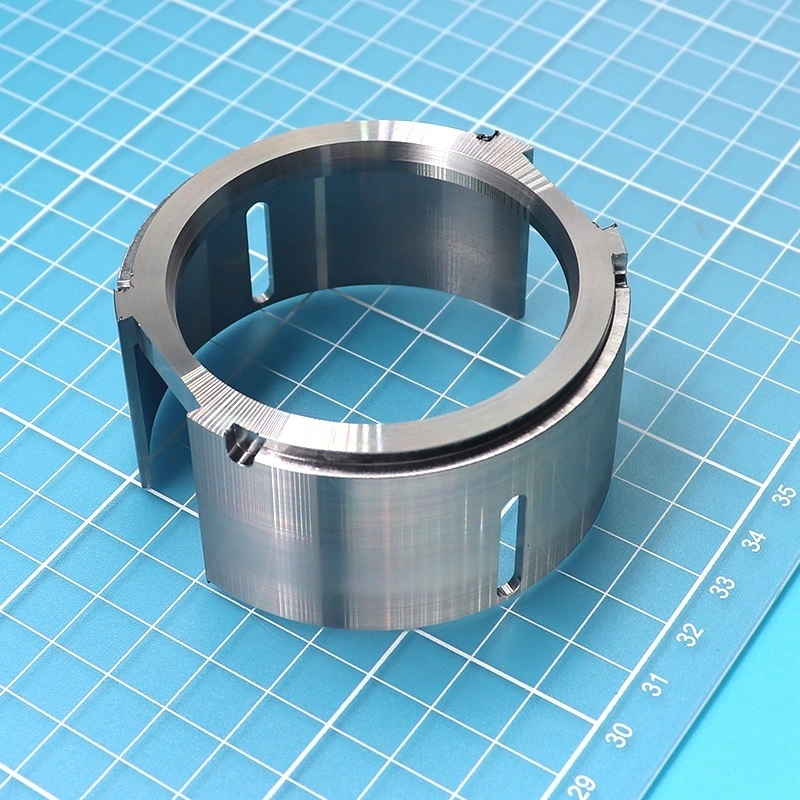

Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

Precision CNC machining AISI 1018 steel service

1. Material Expertise:

AISI 1018 steel is chosen for its exceptional machinability and weldability, allowing us to produce high-precision components efficiently.

2. Custom Solutions:

Our precision CNC machining AISI 1018 steel service is tailored to your specific needs, ensuring that each component meets your exact design and quality requirements.

3. Tight Tolerances:

Leveraging professional CNC technology, we achieve tight tolerances to meet the most demanding specifications, ensuring the accuracy of each machined part.

4. Quality Assurance:

Our rigorous quality control measures guarantee that every component undergoes thorough inspection, maintaining the highest standards of quality and reliability.

5. Versatility:

From simple to complex geometries, our CNC machining capabilities cover a broad spectrum of component designs, providing versatile solutions for diverse industries.

Characteristic

1. Chemical Composition:

- Carbon Content: Approximately 0.18%

- Manganese Content: 0.6% - 0.9%

- Other Elements: Small amounts of sulfur and phosphorus

2. Mechanical Properties:

- Tensile Strength: 63,800 psi

- Yield Strength: 53,700 psi

- Hardness (Brinell): 126

3. Machinability:

- AISI 1018 steel boasts excellent machinability, making it ideal for precision CNC machining operations.

- Its low carbon content contributes to reduced tool wear and smoother surface finishes.

4. Weldability:

- Good weldability, both through conventional welding methods and resistance welding techniques.

- Suitable for welding with various filler materials.

5. Surface Finish:

- AISI 1018 steel offers a good surface finish when subjected to precision CNC machining processes.

- Proper machining techniques ensure the attainment of desired surface smoothness.

6. Advantages:

- Cost-Effective:

AISI 1018 steel is relatively inexpensive compared to other alloys, making it an economical choice for CNC machining projects.

- Machinability:

Its excellent machinability allows for efficient and precise CNC machining, reducing production time and costs.

- Weldability:

Good weldability facilitates ease of assembly and fabrication in various applications.

7. Disadvantages:

- Limited Strength:

While suitable for many applications, AISI 1018 steel may not offer the required strength for highly demanding or high-stress applications.

- Surface Hardness:

Compared to some other alloys, AISI 1018 steel may exhibit lower surface hardness, impacting its wear resistance in certain environments.

Application

1. Automotive Industry:

- Application:

AISI 1018 precision-machined components find use in automotive transmission systems.

- Benefit:

High machinability ensures intricate part designs for improved transmission performance.

2. Aerospace Sector:

- Application:

Critical aircraft components, such as brackets and connectors, benefit from precision CNC machining AISI 1018 steel service.

- Benefit:

The material's weldability and machinability contribute to lightweight yet robust aerospace parts.

3. Electronics Manufacturing:

- Application:

AISI 1018 parts are employed in electronic enclosures and connectors.

- Benefit:

Precision machining allows for intricate designs, crucial for electronic component assembly.

4. Medical Device Production:

- Application:

Surgical instruments and medical equipment housings benefit from precision machining in AISI 1018.

- Benefit:

High-quality surface finish and dimensional accuracy meet stringent medical industry standards.

5. Energy Sector:

- Application:

AISI 1018 components play a role in the production of oil and gas equipment.

- Benefit:

Robust machinability ensures durability in challenging environments.

6. Industrial Equipment Manufacturing:

- Application:

AISI 1018 precision-machined parts are utilized in the production of industrial machinery.

- Benefit:

Customizable machining addresses specific design requirements for diverse industrial applications.

7. Consumer Goods Production:

- Application:

Custom-designed AISI 1018 components find use in consumer appliances.

- Benefit:

The material's versatility and precision machining contribute to the reliability of consumer products.

FAQ