Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

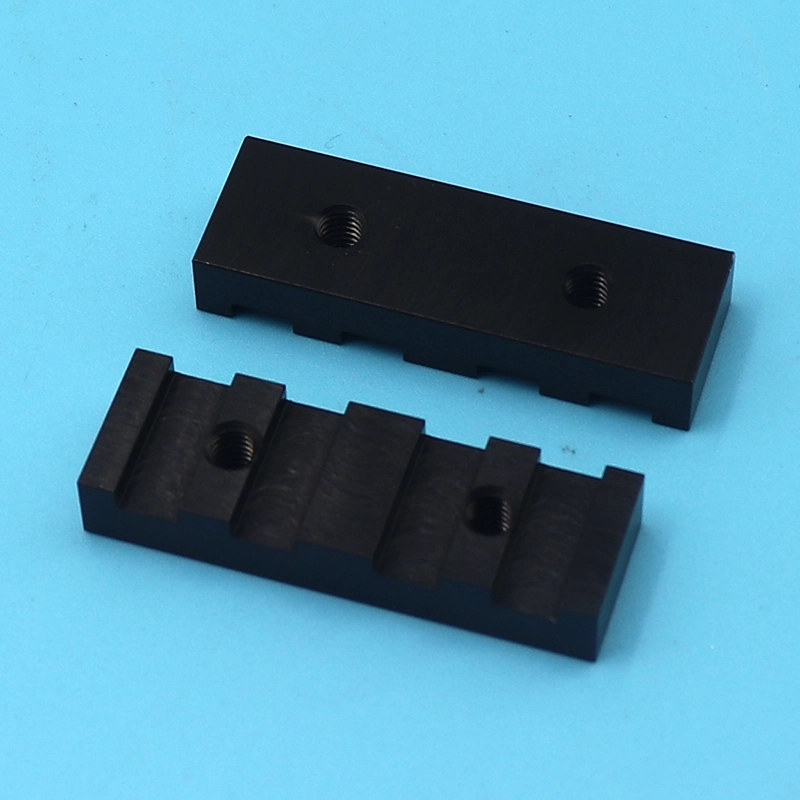

CNC Machined XC48 Steel Parts with Galvanization

Discover the precision and reliability of our CNC Machined XC48 Steel Parts with Galvanization. Meticulously crafted for your custom OEM needs, these components showcase precision craftsmanship with exacting accuracy. Built on the reliability of XC48 steel, they offer durability and strength without sacrificing machinability, thanks to an optimal blend of carbon and manganese.

As a dedicated OEM CNC machining facility, we collaborate closely to deliver high-precision XC48 steel components tailored to your specific requirements. From automotive to industrial machinery, our XC48 steel CNC milling parts find versatile applications, making them integral in assemblies requiring precision. Rigorous quality control measures underpin our commitment to delivering flawless components, ensuring they meet industry standards.

Characteristics

1. Chemical Composition:

- Carbon Content: 0.45-0.55%

- Silicon Content: 0.20-0.40%

- Manganese Content: 0.50-0.80%

- Phosphorus Content: Max 0.035%

- Sulfur Content: Max 0.035%

2. Mechanical Properties:

- Tensile Strength: 540 MPa (Minimum)

- Yield Strength: 420 MPa (Minimum)

- Elongation: 12% (Minimum)

3. Hardness:

- Brinell Hardness: 163 HB

4. Thermal Properties:

- Critical Cooling Rate: 40°C/s

5. Advantages:

- High Strength:

XC48 steel exhibits high tensile and yield strength, making it suitable for applications demanding robustness.

- Good Machinability:

The steel's composition contributes to excellent machinability, facilitating precision CNC milling processes.

- Wear Resistance:

XC48's hardness enhances its resistance to wear, prolonging the lifespan of machined parts.

6. Disadvantages:

- Limited Corrosion Resistance:

XC48 steel is susceptible to corrosion in certain environments, requiring protective measures or alternative materials for corrosive applications.

- Weldability Challenges:

Welding XC48 steel may pose challenges due to its composition, necessitating careful consideration during fabrication.

Application

1. Automotive Excellence:

CNC Machined XC48 Steel Parts with Galvanization contribute to the automotive sector, enhancing performance and durability. From engine components to chassis elements, their robust nature ensures optimal functionality, meeting the stringent standards of the automotive industry.

2. Industrial Machinery:

In the realm of industrial machinery, XC48 steel components play a pivotal role. Applications range from gear manufacturing to intricate parts of heavy machinery. The resilience of XC48 steel ensures these parts withstand the rigors of industrial operations.

3. Precision Instrumentation:

Precision instruments demand components that embody accuracy. XC48 steel CNC milling parts find applications in crafting components for delicate instruments where precision is paramount, ensuring reliable performance.

4. Aerospace Engineering:

The aerospace industry leverages the strength and reliability of XC48 steel CNC milling parts. From structural components to critical parts in aircraft systems, these components contribute to the safety and performance of aerospace engineering.

5. Energy Sector Reliability:

XC48 steel components are integral to the energy sector, where reliability is non-negotiable. Applications include components for power generation equipment and machinery critical to the energy production process.

6. Medical Equipment:

In the realm of medical engineering, XC48 steel CNC milling parts find applications in manufacturing medical equipment. Their precise engineering ensures the reliability and longevity of critical components in medical devices.

7. Custom OEM Solutions:

As a custom OEM CNC machining facility, we specialize in tailoring CNC machined XC48 steel parts with Galvanization to meet the unique requirements of various industries. Our collaborative approach ensures that the applications of XC48 steel CNC milling parts are seamlessly integrated into diverse projects.

Exploring Galvanization for Metal Protection

Understanding Galvanization:

Galvanization is a methodical process designed to protect metal surfaces by applying a layer of zinc. Two primary methods are widely used: hot-dip galvanization and electrogalvanization, each with distinct characteristics catering to specific needs.

1. Hot-Dip Galvanization:

This method involves immersing metals in a molten zinc bath, establishing a metallurgical bond that enhances durability and resilience.

2. Electrogalvanization:

Electrogalvanization delicately deposits a thin layer of zinc through an electric current, offering corrosion resistance and an aesthetically pleasing finish.

Benefits of Galvanization:

Galvanization is a comprehensive approach to fortify metals, offering several key benefits:

1. Corrosion Resistance:

The zinc barrier effectively shields metals from corrosive elements, providing a robust defense.

2. Longevity:

Galvanized surfaces exhibit an extended lifespan, emphasizing the durability of the process.

3. Low Maintenance:

Minimal upkeep is required for galvanized surfaces, contributing to practical long-term maintenance.

4. Cost-Effective:

Galvanization proves to be a cost-effective investment, aligning durability with economic considerations.

Applications Across Industries:

Galvanization finds extensive use across various sectors, contributing to:

1. Construction:

Structural steel and fasteners benefit from galvanization, especially in challenging construction environments.

2. Automotive Industry:

Galvanization is applied to automotive components for resilience against environmental elements.

3. Infrastructure:

Guardrails, bridges, and utility poles rely on galvanization for enduring corrosion resistance.

4. Agricultural Equipment:

Galvanized coatings enhance the resilience of agricultural equipment against harsh environmental conditions.

FAQ