Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

Custom Precision CNC machined XC38 steel parts with black oxide coating

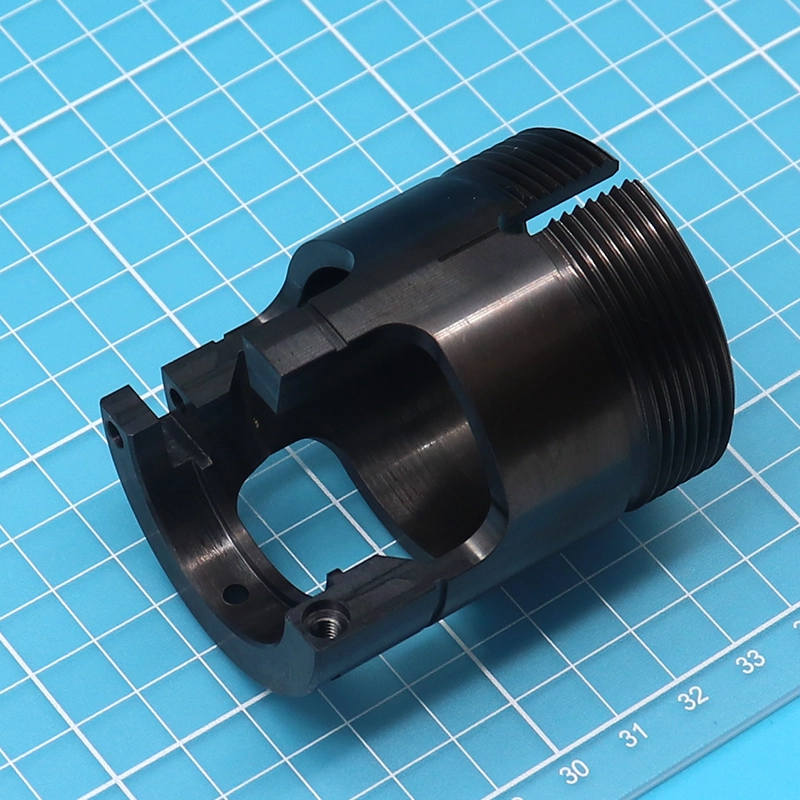

Welcome to our CNC machining facility, we offer Custom Precision CNC machined 1040 steel parts with black oxide coating. Our team is experienced in producing a wide range of components tailored to your specifications.

Utilizing reliable CNC milling and turning techniques, we manufacture 1040 steel parts with precision and accuracy. Our focus is on delivering high-quality, tailored solutions to meet your unique needs.

In addition to precision machining, we provide black oxide coating to enhance the durability and corrosion resistance of your parts. This coating option adds value to your components by extending their lifespan and maintaining their aesthetic appeal.

Characteristics

1. Composition:

1040 steel is a medium-carbon steel alloy containing approximately 0.40% carbon, providing a balance between ductility and strength.

2. Tensile Strength:

With a tensile strength of 580 MPa (84,000 psi) and a yield strength of 370 MPa (54,000 psi), 1040 steel exhibits robust mechanical properties suitable for various applications.

3. Hardness:

It has a hardness range of 160 to 180 Brinell hardness (HB), offering good machinability and wear resistance when properly heat-treated.

4. Machinability:

1040 steel demonstrates excellent machinability, making it suitable for precision CNC machining processes such as milling, turning, and drilling.

5. Weldability:

This steel grade exhibits fair weldability, allowing for ease of fabrication and assembly in welded structures and components.

Advantages of 1040 Steel:

1. Strength-to-Weight Ratio:

The balanced composition of 1040 steel provides a favorable strength-to-weight ratio, making it ideal for applications requiring high strength without excessive weight.

2. Machinability:

Its excellent machinability facilitates efficient machining processes, resulting in reduced production times and costs.

3. Versatility:

1040 steel offers versatility in fabrication, allowing for the production of a wide range of components for various industries, including automotive, aerospace, and machinery.

Disadvantages of 1040 Steel:

1. Limited Hardenability:

While 1040 steel can be hardened through heat treatment, its hardenability is limited compared to higher-carbon steels, potentially restricting its use in applications requiring extreme hardness.

2. Corrosion Susceptibility:

Despite exhibiting fair corrosion resistance, 1040 steel may be susceptible to corrosion in certain environments, necessitating proper coating or protection measures.

Product Advantages

1. Automotive Industry:

- Engine Components:

Custom precision CNC machined 1040 steel parts with black oxide coating are utilized in engine components such as crankshafts, camshafts, and connecting rods. The robustness and wear resistance of these parts contribute to the efficiency and longevity of automotive engines.

2. Aerospace Industry:

- Landing Gear Components:

In aircraft manufacturing, 1040 steel parts with black oxide coating are employed in landing gear components like axles, brackets, and hinges. These parts require high strength, corrosion resistance, and precise machining, making 1040 steel an ideal choice.

3. Machinery Manufacturing:

- Gear Assemblies:

Within machinery manufacturing, 1040 steel parts with black oxide coating find application in gear assemblies for various industrial equipment. The combination of strength, machinability, and surface protection enhances the performance and service life of gear systems.

4. Construction Sector:

- Structural Supports:

Custom precision CNC machined 1040 steel parts with black oxide coating are utilized in structural supports such as beams, columns, and brackets in construction projects. The corrosion resistance and structural integrity of these parts ensure the stability and safety of buildings and infrastructure.

5. Medical Device Manufacturing:

- Surgical Instruments:

In the medical device industry, 1040 steel parts with black oxide coating are employed in the production of surgical instruments like forceps, scissors, and clamps. The precision machining and surface protection enhance the functionality and sterilization of these critical instruments.

6. Oil and Gas Sector:

- Valve Components:

Within the oil and gas sector, 1040 steel parts with black oxide coating are utilized in valve components for pipelines and drilling equipment. The combination of strength, corrosion resistance, and sealing properties ensures reliable performance in demanding environments.

FAQ