Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

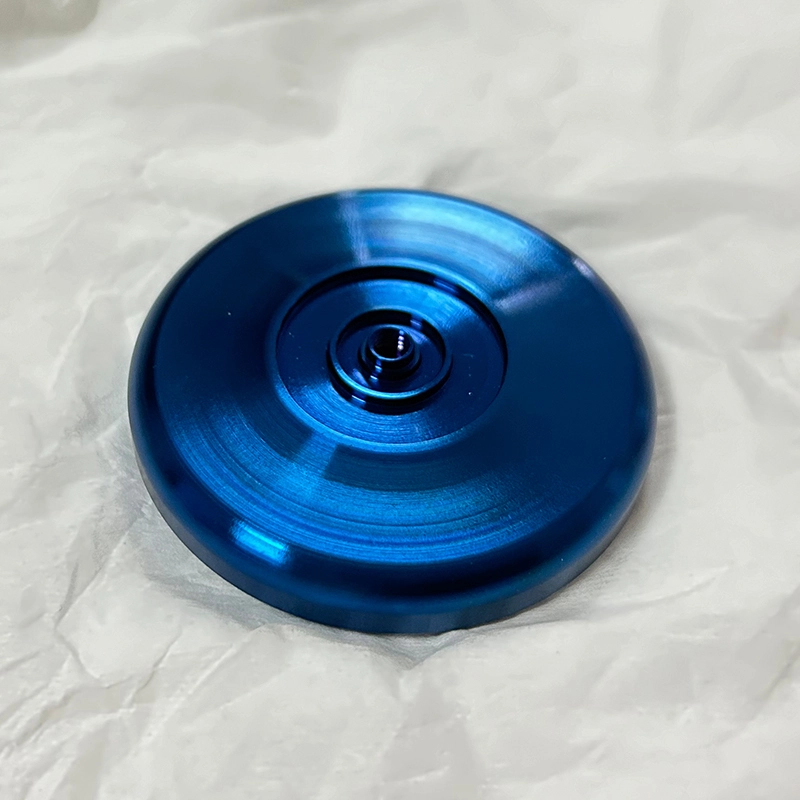

Precision CNC Turning Ti 6AL-4V Titanium Service With PVD Coating For Custom Parts

Our precision CNC turning services offer unparalleled expertise in crafting Ti 6AL-4V titanium parts with the added advantage of PVD coating. We specialize in delivering high-quality, custom OEM solutions for diverse industries.

The use of Ti 6AL-4V titanium provides exceptional strength, corrosion resistance, and low weight, making it ideal for various applications.

The incorporation of PVD coating enhances the surface properties, providing increased hardness, wear resistance, and aesthetic appeal to the titanium parts. Our commitment to quality and reliability makes us a trusted partner for OEMs seeking tailored solutions for their CNC machining needs.

Characteristic

1. Density:

- Ti 6AL-4V has a density of approximately 4.43 g/cm³, offering a lightweight yet sturdy option for precision CNC turning.

2. Tensile Strength:

- The tensile strength of Ti 6AL-4V ranges from 900 to 1000 MPa, providing excellent strength comparable to many steel alloys.

3. Melting Point:

- With a melting point of around 1668°C (3034°F), Ti 6AL-4V exhibits robust thermal stability during precision CNC turning processes.

4. Thermal Conductivity:

- Ti 6AL-4V has a thermal conductivity ranging from 6.7 to 7.5 W/(m·K), ensuring efficient heat dissipation during machining.

5. Coefficient of Thermal Expansion:

- The coefficient of thermal expansion is approximately 8.4 µm/m·K, minimizing the risk of distortion during precision CNC turning.

6. Corrosion Resistance:

- Ti 6AL-4V demonstrates excellent corrosion resistance, making it suitable for applications in challenging environments.

Advantages:

- High Strength-to-Weight Ratio:

Ti 6AL-4V offers a remarkable strength-to-weight ratio, making it ideal for applications where both strength and weight are critical factors.

- Corrosion Resistance:

The alloy's corrosion resistance ensures longevity and reliability in various environments.

- Biocompatibility:

Ti 6AL-4V is biocompatible, making it suitable for medical applications, such as implants.

Drawbacks:

- Cost:

Ti 6AL-4V titanium is relatively expensive compared to some other materials, impacting the overall cost of precision CNC turning.

- Machinability:

While machinable, Ti 6AL-4V can pose challenges due to its toughness, requiring appropriate machining techniques.

Application

1. Aerospace Industry:

Ti 6AL-4V's exceptional strength, low weight, and resistance to corrosion make it a preferred material for aerospace components. Precision CNC turning Ti 6AL-4V titanium service with PVD coating for custom parts offer enhanced durability and wear resistance, crucial for aerospace applications.

2. Medical Devices:

The biocompatibility of Ti 6AL-4V makes it suitable for medical implants. Precision CNC turning ensures intricate components for medical devices, and PVD coating adds an extra layer of protection, reducing wear and extending the life of the parts.

3. Automotive Sector:

Ti 6AL-4V titanium parts contribute to lightweight designs in the automotive industry, improving fuel efficiency. PVD-coated components enhance the durability of critical parts, ensuring longevity and reliability.

4. Oil and Gas Equipment:

In harsh environments, where corrosion resistance is paramount, Ti 6AL-4V parts excel. PVD coating further fortifies these components against wear and corrosion, making them ideal for oil and gas exploration equipment.

5. Precision Machinery:

Applications requiring precision and durability, such as high-performance machinery, benefit from Ti 6AL-4V components. PVD coating ensures that these parts withstand the rigors of heavy-duty operations.

6. Sporting Goods:

Ti 6AL-4V's lightweight yet sturdy nature makes it suitable for sporting goods. Whether in bicycles, golf clubs, or other equipment, precision CNC turning delivers customized components with PVD coating for added resilience.

7. Electronics and Gadgets:

The electronics industry utilizes Ti 6AL-4V parts in devices where weight and durability matter. PVD coating enhances the aesthetic appeal and protects these components from the demands of daily use.

8. Energy Sector:

Ti 6AL-4V's resilience makes it valuable in the energy sector. PVD-coated components, used in turbines and energy exploration tools, exhibit prolonged life and resistance to environmental stressors.

In every application, our precision CNC turning Ti 6AL-4V titanium service with PVD coating for custom parts, coupled with advanced PVD coating, ensure that the components meet the highest standards of quality, durability, and performance.

PVD Coating

1. Process Explanation:

- PVD coating involves the deposition of thin films on the substrate material through a vacuum process. Common coating materials include titanium nitride (TiN), titanium aluminum nitride (TiAlN), and chromium nitride (CrN).

2. Vacuum Chamber Operation:

- The substrate material is placed in a vacuum chamber, and the coating material is evaporated. The vaporized material condenses on the substrate, forming a thin, adherent coating.

3. Benefits of PVD Coating:

- Enhanced Hardness:

PVD coatings significantly increase the hardness of the substrate material, enhancing wear resistance.

- Improved Corrosion Resistance:

The coated surface exhibits heightened resistance to corrosion, ensuring longevity in challenging environments.

- Enhanced Aesthetics:

PVD coatings provide a decorative finish, adding visual appeal to machined components.

4. Applications in CNC Machining:

- PVD coating finds extensive use in CNC machining for various components, including precision parts, cutting tools, and decorative elements. It serves to extend the lifespan and functionality of machined products.

FAQ