Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

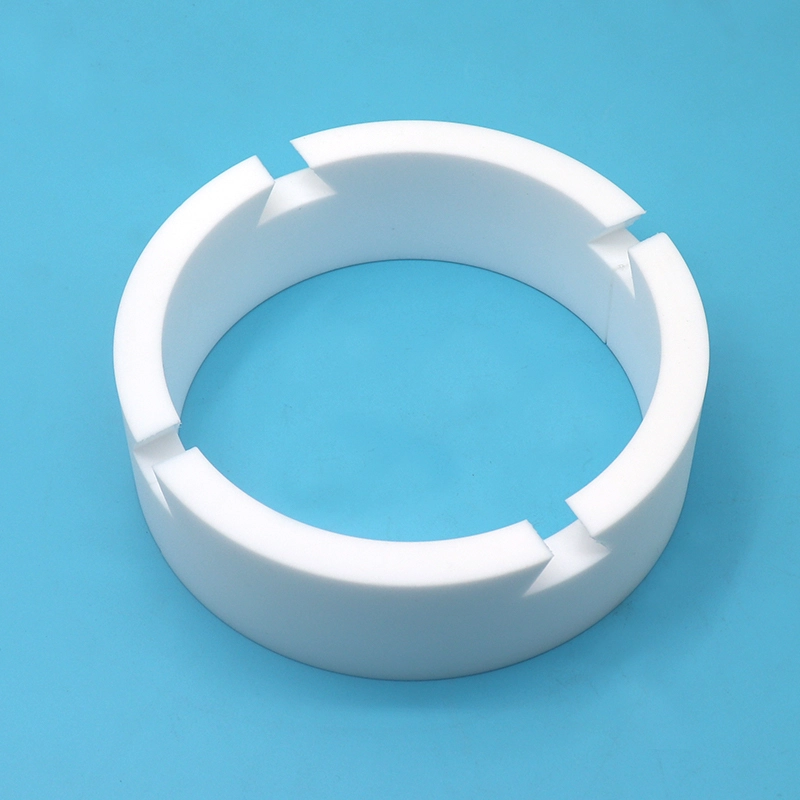

CNC Machined Custom PTFE Sealing Rings

At our CNC machining facility, we good at crafting bespoke PTFE sealing rings to meet the exacting needs of diverse industries. The CNC machined custom PTFE sealing rings offer exceptional sealing performance, chemical resistance, and thermal stability. With a focus on quality and tailored solutions, our CNC machining services ensure the production of high-precision PTFE sealing rings that consistently meet stringent specifications. Trust us for reliable OEM solutions, delivering precision, durability, and adherence to the high industry standards.

Characteristic

1. Coefficient of Friction:

PTFE, known for its low friction, boasts a coefficient as low as 0.05, minimizing resistance and ensuring smooth operation in dynamic sealing applications.

2. Temperature Resistance:

PTFE excels in temperature resistance, withstanding a broad range from -200°C to 260°C. This property makes it suitable for applications in extreme thermal environments.

3. Chemical Inertness:

With exceptional chemical inertness, PTFE remains unaffected by various chemicals, acids, and bases, ensuring stability and reliability in diverse chemical environments.

4. Dielectric Strength:

PTFE possesses high dielectric strength, making it an excellent insulator. This property is crucial in electrical applications where insulation integrity is paramount.

5. Surface Tension:

The low surface tension of PTFE, quantified at approximately 18 dyn/cm, contributes to its non-stick properties, preventing adhesion of foreign substances and enhancing cleanliness.

6. Water Absorption:

PTFE exhibits minimal water absorption, with a water absorption rate lower than 0.01%. This property ensures dimensional stability in varying humidity conditions.

7. Tensile Strength:

While PTFE has a lower tensile strength compared to some metals, its tensile strength of around 20 MPa is sufficient for sealing applications, providing structural integrity.

Advantages:

- Chemical Resistance:

PTFE's resistance to chemicals enhances its applicability in corrosive environments.

- Low Friction:

The low coefficient of friction reduces wear and tear, extending the lifespan of sealing components.

- Wide Temperature Range:

PTFE's ability to endure extreme temperatures makes it suitable for diverse industrial conditions.

Disadvantages:

- Cold Flow:

PTFE may exhibit cold flow under prolonged stress, causing deformation over time.

- Limited Load-Bearing Capacity:

Compared to some metals, PTFE has a lower load-bearing capacity.

Application

1. Aerospace Industry:

CNC Machined custom PTFE sealing rings play a crucial role in aerospace applications, providing effective sealing solutions for hydraulic systems, fuel systems, and engine components. Their resistance to extreme temperatures and compatibility with aviation fuels make them vital in ensuring the reliability of critical aircraft systems.

2. Automotive Sector:

In the automotive industry, these sealing rings contribute to the efficiency of engines and transmissions. Their ability to withstand harsh automotive fluids, such as oil and coolant, makes them integral components for maintaining the longevity and functionality of automotive systems.

3. Medical Devices:

They are employed in medical devices where aseptic conditions are imperative. Their biocompatibility, chemical resistance, and precision sealing make them suitable for various medical applications, including pharmaceutical manufacturing and laboratory equipment.

4. Oil and Gas Equipment:

The resilience of PTFE sealing rings in corrosive environments positions them as ideal components in oil and gas equipment. They effectively seal components in pumps, valves, and pipelines, contributing to the overall integrity and safety of oil and gas operations.

5. Food and Beverage Processing:

In food and beverage processing equipment, where hygiene is paramount, they ensure contamination-free environments. Their resistance to chemicals and high temperatures makes them suitable for sealing applications in processing machinery.

6. Industrial Machinery:

CNC Machined custom PTFE sealing rings are extensively utilized in various industrial machinery, including pumps, compressors, and hydraulic systems. Their versatility and ability to maintain sealing integrity under challenging conditions contribute to the reliable operation of industrial equipment.

7. Electronics and Semiconductor Manufacturing:

Precision is critical in electronics and semiconductor manufacturing. PTFE sealing rings, with their inert nature and resistance to static charge buildup, find applications in semiconductor manufacturing equipment, ensuring a controlled and contamination-free environment.

These diverse applications underscore the versatility and effectiveness of CNC machined custom PTFE sealing rings across critical industries, where precision and reliability are non-negotiable.

FAQ