Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

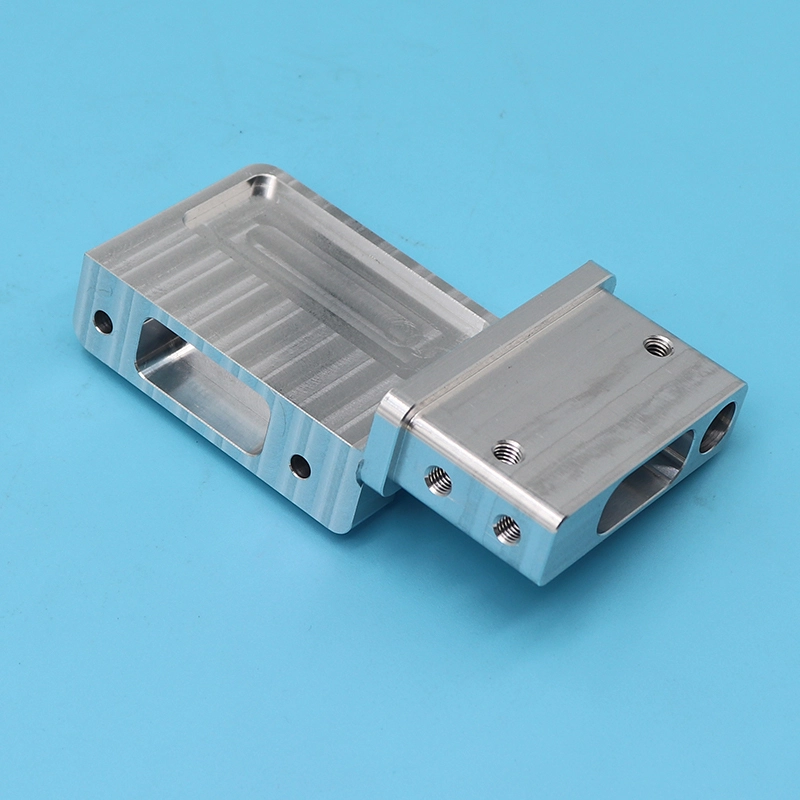

RuiXing MFG丨Custom CNC milled 6082 aluminum parts

Delivering Excellence in Custom CNC Milling:

At our OEM CNC machining facility, we craft high-quality 6082 aluminum parts with meticulous precision. Our professional CNC milling processes guarantee consistency and accuracy, meeting the exact specifications of your projects.

6082 aluminum, renowned for its excellent machinability and mechanical properties, is a preferred choice for industries demanding reliability and durability. Our expertise extends to handling this material with finesse, ensuring the production of top-notch components.

Our custom CNC milled 6082 aluminum parts find applications across diverse industries, including automotive, aerospace, and machinery. From intricate components to structural elements, our precision-milled parts contribute to the seamless functioning of various systems.

Characteristic

I. Numerical Parameters:

1. Tensile Strength: 260 MPa

2. Yield Strength: 240 MPa

3. Elongation at Break: 10%

4. Hardness (Brinell): 95 HB

5. Density: 2.70 g/cm³

6. Thermal Conductivity: 180 W/(m·K)

7. Melting Point: 555°C

8. Machinability Rating (compared to 2011 at 100%): 80%

II. Advantages:

1. Excellent Machinability:

6082 aluminum exhibits high machinability, allowing for precise and efficient CNC milling.

2. Good Strength-to-Weight Ratio:

Its combination of strength and low density contributes to a favorable strength-to-weight ratio.

3. Corrosion Resistance:

The material's corrosion resistance ensures durability in various environments.

4. Weldability:

6082 aluminum is weldable, facilitating the fabrication of complex structures.

III. Disadvantages:

1. Not Heat-Treatable:

Unlike some other aluminum alloys, 6082 is not heat-treatable, limiting post-machining heat treatment options.

2. Limited Cold Forming:

Cold forming may lead to reduced mechanical properties, limiting its applicability in certain manufacturing processes.

Application

I. Automotive Industry:

Custom CNC milled 6082 aluminum parts find extensive use in the automotive sector, contributing to the production of critical components such as engine parts, transmission components, and structural elements. The material's lightweight yet durable nature makes it ideal for improving fuel efficiency and overall vehicle performance.

II. Aerospace Applications:

In aerospace engineering, precision is paramount. They meet the stringent demands of this industry, serving in applications like aircraft structural components, landing gear, and hydraulic systems. The material's strength and reliability contribute to the safety and performance of aerospace systems.

III. Machinery and Equipment:

Custom CNC milling of 6082 aluminum is integral to the machinery and equipment manufacturing sector. These precision components are utilized in the production of gears, shafts, and other critical elements, ensuring optimal performance and longevity in various types of machinery.

IV. Electronics and Technology:

The electronics industry benefits from the use of them in the production of enclosures, heat sinks, and connectors. The material's excellent thermal conductivity and corrosion resistance make it an ideal choice for applications requiring durability and reliability.

V. Medical Equipment:

In the medical field, precision and hygiene are paramount. They play a vital role in the manufacturing of medical devices, diagnostic equipment, and surgical instruments. The material's biocompatibility and precision contribute to the quality and safety of medical technologies.

VI. Renewable Energy Systems:

Components used in renewable energy systems, such as wind turbines and solar panel frameworks, benefit from the custom CNC milled 6082 aluminum parts. The material's strength and resistance to environmental factors make it suitable for ensuring the longevity and reliability of renewable energy infrastructure.

FAQ