Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

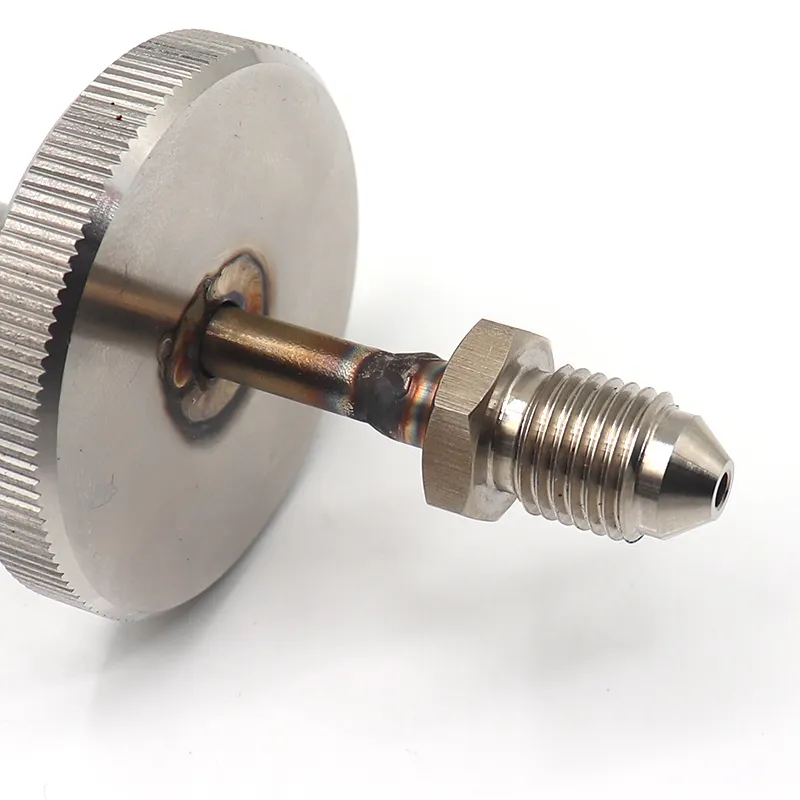

Stainless Steel Turned Components by Ruixing

Product details of the stainless steel turned components

Product Description

When manufacturing Ruixing stainless steel turned components, we have a special team to take charge of its design. The product has been tested for many times under the rigorous quality control system. With excellent economic returns, this product is considered to be the most promising product on the market.

TIG Welding Description

1. Arc Voltage:

TIG welding operates at a relatively low arc voltage range, typically between 10 and 20 volts. This characteristic ensures controlled heat input, making it suitable for thin materials and intricate components.

2. Current Range:

The current range in TIG welding spans from 5 to 350 amperes. This broad range allows for flexibility in welding various materials with distinct thicknesses, offering adaptability in CNC machining applications.

3. Shielding Gas:

Argon or a mixture of argon and helium is commonly used as shielding gas in TIG welding. The inert nature of these gases prevents atmospheric contamination, ensuring clean and precise welds.

4. Electrode Diameter:

Tungsten electrodes with diameters ranging from 0.5 to 4.0 millimeters are employed in TIG welding. The choice of electrode diameter influences the welding current and the intricacy of the weld.

Advantages:

A. Precision Welds:

TIG welding excels in delivering precision welds, making it suitable for applications where accuracy is critical, such as CNC machining.

B. Clean Welds:

The use of inert shielding gases ensures minimal spatter and a clean weld environment, contributing to the aesthetic and functional aspects of CNC machined parts.

C. Versatility:

TIG welding accommodates a wide range of materials, including aluminum, stainless steel, and titanium, enhancing its applicability in diverse CNC machining projects.

Disadvantages:

A. Speed of Welding:

TIG welding tends to be slower compared to some other welding processes, impacting production speed in high-volume CNC machining scenarios.

B. Skill Dependency:

Achieving optimal results in TIG welding requires a high level of skill and precision, making it crucial to have experienced welders involved in the CNC machining process.

C. Limited Thickness Range:

While suitable for thin materials, TIG welding may face limitations when dealing with thicker sections.

Application

1. Aerospace Industry:

In the aerospace sector, where safety and precision are paramount, TIG welding is instrumental. The method's ability to create seamless, high-strength joints makes it ideal for crafting critical components in aircraft, ensuring the structural integrity necessary for safe flights.

2. Automotive Manufacturing:

Automotive manufacturing relies on precision TIG welding services for assembling components with precision. From chassis to exhaust systems, TIG welding provides clean, precise welds that enhance the longevity and structural strength of automotive parts.

3. Medical Equipment Production:

The medical industry demands precision at the highest level. TIG welding finds applications in manufacturing medical equipment, where the method's ability to produce contamination-free, high-strength welds is crucial for maintaining the integrity of life-saving devices.

4. Energy Sector:

In the energy sector, TIG welding is widely employed in the fabrication of pipelines and nuclear components. The method's capability to create robust, corrosion-resistant welds ensures the longevity and safety of critical energy infrastructure.

5. Precision Instrumentation:

For the production of precision instruments and laboratory equipment, TIG welding is preferred. The method's precision and control contribute to the creation of intricate components that are vital in scientific research and experimentation.

6. Custom CNC Machining:

Within the realm of custom CNC machining, precision TIG welding services seamlessly integrate into the manufacturing process. This integration allows for the creation of components with impeccable welds, ensuring the structural reliability and precision required in bespoke CNC machined parts.

7. Marine Engineering:

In marine engineering, where components face harsh environmental conditions, TIG welding excels. It is applied in the construction of ship components and offshore structures, providing welds that resist corrosion and enhance structural durability.

8. Electronics Manufacturing:

Precision is paramount in electronics manufacturing. TIG welding finds applications in creating connections in electronic components, ensuring reliable conductivity and structural integrity in devices ranging from consumer electronics to industrial equipment.

FAQ

Company Feature

• Ruixing has excellent customer service management team and professional customer service personnel. We can provide comprehensive, thoughtful, and timely services for customers.

• Ruixing was founded in Having accumulated experience for years, we are now a leading enterprise in the industry.

• We own conductive conditions for material delivery. Nearby, there is a prosperous market, developed communication, and convenient transportation.

For bulk purchase of the products, please contact us.