Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

Custom Tungsten Carbide Parts None Wholesale - Ruixing

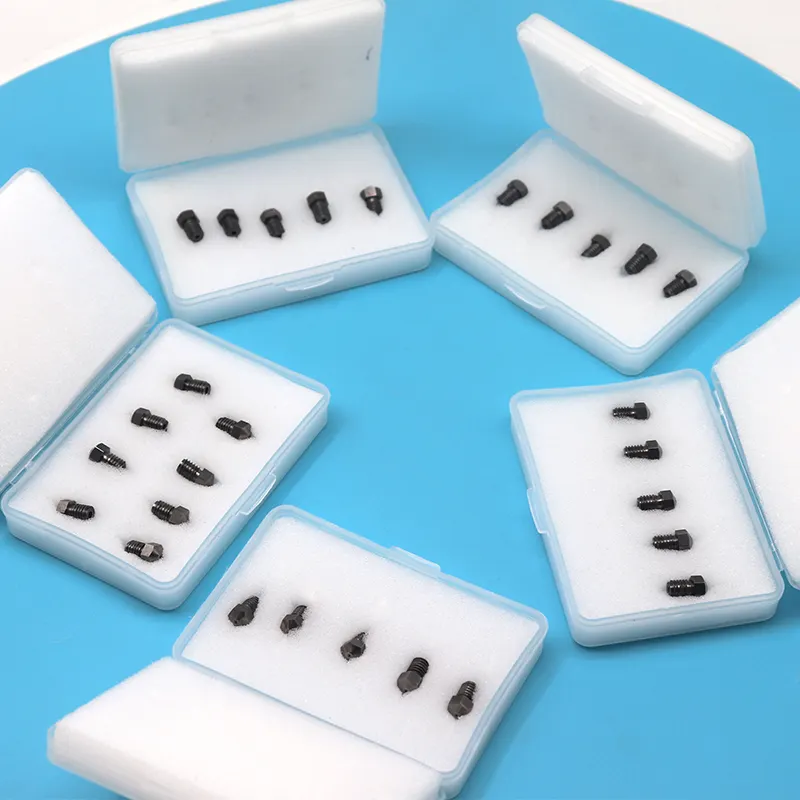

Product details of the custom tungsten carbide parts

Product Overview

The production of Ruixing custom tungsten carbide parts is carried out according to industry production standard. This product has passed the inspection of our professional QC team and the authoritative third party. It is the exquisite service that Ruixing attracts many customers.

Product Description

The specific details for custom tungsten carbide parts of Ruixing are mainly reflected in the following aspects.

Characteristic

1. Density (g/cm³):

Tungsten steel boasts a high density of approximately 15.6 g/cm³, contributing to its robust and heavy-duty nature.

2. Hardness (HRC):

With a hardness rating exceeding 90 HRC, tungsten steel is exceptionally hard, providing outstanding wear resistance.

3. Melting Point (°C):

Tungsten steel has a high melting point of about 3,422°C, ensuring stability under extreme temperatures.

4. Thermal Conductivity (W/m·K):

Its thermal conductivity, approximately 120 W/m·K, enables efficient heat dissipation during machining processes.

5. Coefficient of Thermal Expansion (10^-6/°C):

Tungsten steel exhibits a low coefficient of thermal expansion (4.5–6.0 x 10^-6/°C), minimizing dimensional changes under temperature variations.

Advantages:

1. High Hardness:

Exceptional hardness contributes to prolonged tool life and wear resistance in various machining applications.

2. Temperature Resistance:

High melting point and low thermal expansion make tungsten steel suitable for applications in extreme temperature environments.

3. Wear Resistance:

The hardness of tungsten steel provides excellent wear resistance, ensuring durability in demanding machining processes.

Disadvantages:

1. Brittleness:

Tungsten steel's inherent hardness can lead to brittleness, posing challenges in certain machining applications.

2. Machinability:

Due to its hardness, tungsten steel presents difficulties in machining processes, requiring specialized tools and techniques.

Challenges in CNC Machining:

Precision CNC machining of tungsten steel poses specific challenges:

1. Tool Wear:

The extreme hardness of tungsten steel accelerates tool wear, necessitating frequent tool changes.

2. Vibration and Chatter:

Tungsten steel's hardness can cause increased vibration and chatter during machining, impacting surface finish.

In the realm of custom CNC machining, understanding these characteristics and challenges is crucial for optimizing processes and achieving precision in crafting components like 3D printer nozzles.

Application

In the realm of precision engineering, our custom CNC machined tungsten steel parts find diverse applications, demonstrating the versatility of these components across various industries. The meticulous craftsmanship of our OEM CNC machining facility ensures that each tungsten steel part meets stringent standards for durability, wear resistance, and precision. Here are six notable examples of tungsten steel parts in specific industries:

1. Oil and Gas Sector - Drill Bit Inserts:

Tungsten steel components contribute to the production of tungsten carbide inserts for rotary drill bits, enhancing hardness and wear resistance for optimal drilling efficiency in challenging geological conditions.

2. Aerospace Industry - Valve Spools:

Tungsten steel parts play a crucial role in crafting precision valve spools for aerospace hydraulic systems, ensuring reliable fluid flow regulation under extreme aerospace conditions.

3. Medical Equipment - Surgical Instruments:

Tungsten steel's durability and precision are harnessed in crafting components for surgical instruments, ensuring longevity and reliability in critical medical applications.

4. Automotive Manufacturing - Transmission Components:

Tungsten steel's wear resistance is utilized in crafting precision components for automotive transmissions, contributing to the efficiency and durability of these critical parts.

5. Electronics - Semiconductor Tooling:

Tungsten steel parts are integral to the creation of high-precision tooling for semiconductor manufacturing, where durability and precision are paramount for intricate electronic components.

6. Energy Sector - Turbine Blades:

In the energy sector, tungsten steel components are employed in crafting precision turbine blades, withstanding extreme conditions to ensure the efficient generation of power.

FAQ

Company Advantages

Located in shen zhen, Shenzhen Ruixing Precision MFG specializes in processing and sales and its products mainly include CNC Machining Services,Sheet Metal Fabrication. In order to provide better service, our company follows the service concept of 'professional, concentrated, honest, responsible' and the service principle of 'innovation, hard work, sincerity, responsibility'. We insist on obtaining customer's trust and support with sincerity and quality, so as to achieve mutual benefit. Ruixing focuses on talents and virtue. A group of elite teams is cultivated based on that. They are cooperative and well-communicated. Ruixing always provides customers with reasonable and efficient one-stop solutions based on the professional attitude.

If interested in our products, you are welcomed to contact customer service staff for consultation!