Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

Custom CNC precision 6061 aluminum machining service

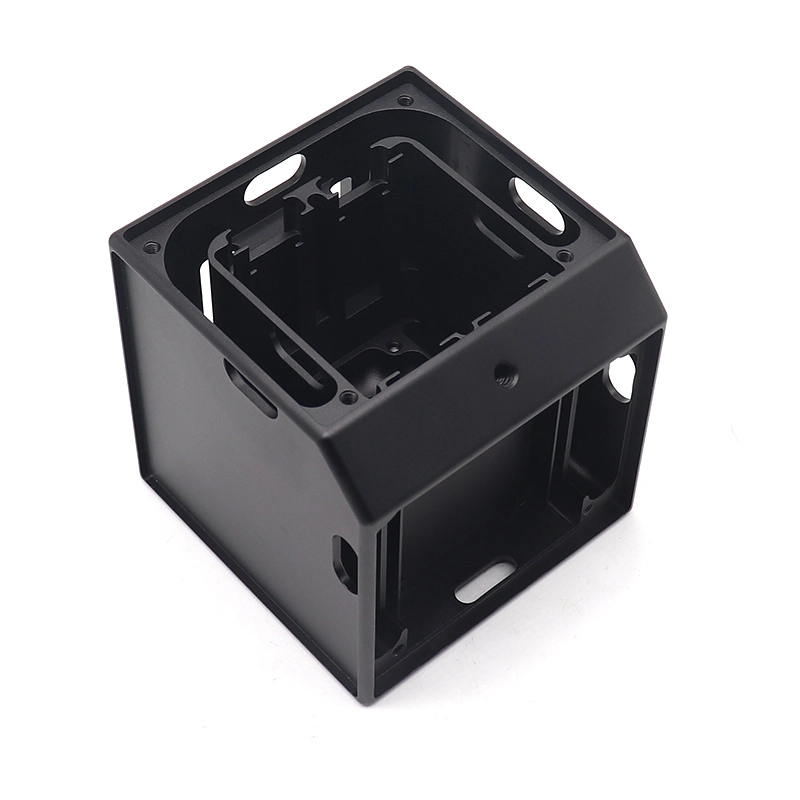

At our CNC machining facility, we specialize in providing custom solutions for machining 6061 aluminum components. As a dedicated OEM partner, we deliver precise and reliable machining services tailored to meet your specific needs.

Our experienced team of machinists employs professional equipment to ensure the accurate production of 6061 aluminum parts. This versatile material, known for its balanced properties of strength and machinability, is suitable for a wide range of applications across various industries.

From intricate designs to complex geometries, our CNC machining expertise enables us to manufacture components that align with your unique specifications. Partner with us for dependable, high-quality machining services designed to fulfill the requirements of your OEM projects.

Characteristic

1. Precision Tolerances:

Achieving exceptional precision, our custom CNC precision 6061 aluminum machining service maintains tight tolerances as low as +/- 0.02mm, ensuring exact conformity to design specifications.

2. Surface Finish Control:

We offer controlled surface finishes on 6061 aluminum parts, ranging from matte to glossy, providing aesthetic versatility for varied applications.

3. Material Composition:

Crafted from the resilient 6061 aluminum alloy, our service ensures a balanced combination of strength, corrosion resistance, and machinability.

4. Anodized Coating Thickness:

The anodized coating thickness on custom aluminum parts can be precisely controlled, typically ranging from 5 to 25 microns, ensuring durability and corrosion resistance.

5. Complex Geometries and Intricate Designs:

Leveraging CNC milling capabilities, intricate designs and complex geometries are achieved, allowing for versatility in component shapes and configurations.

Advantages:

a. Enhanced Aesthetics:

The anodized finish on custom aluminum parts enhances visual appeal, offering various colors and textures for customizable aesthetics.

b. Corrosion Resistance:

Anodized coating provides superior corrosion resistance, ensuring longevity by protecting aluminum parts from environmental elements.

c. Improved Surface Hardness:

Anodizing enhances surface hardness, increasing resistance to scratches, abrasion, and wear, ensuring durability in demanding applications.

d. Thermal Insulation:

Anodized 6061 aluminum parts exhibit improved thermal insulation properties, making them suitable for applications requiring heat dissipation or thermal barrier properties.

Product Advantages

1. Aerospace Industry - Structural Components:

Precision machining of 6061 aluminum is crucial for producing lightweight yet sturdy structural components in aerospace, such as aircraft frames, panels, and brackets.

2. Automotive Sector - Engine Parts:

Within the automotive realm, our custom CNC precision 6061 aluminum machining service is utilized for crafting precise engine components from 6061 aluminum, ensuring optimal performance and durability.

3. Electronics Manufacturing - Heat Sinks:

In electronics, the machining of 6061 aluminum is employed to create efficient heat sinks, playing a vital role in heat dissipation for electronic devices.

4. Medical Equipment - Instrument Housings:

The medical industry benefits from CNC precision machining for manufacturing instrument housings and components from 6061 aluminum, maintaining a delicate balance between strength and weight.

5. Industrial Equipment - Gearbox Housings:

For industrial applications, our machining service is instrumental in producing gearbox housings and components, where the durability of 6061 aluminum is paramount.

6. Renewable Energy - Wind Turbine Parts:

In the renewable energy sector, CNC machining is applied to create precise components for wind turbines, leveraging the lightweight and corrosion-resistant properties of 6061 aluminum.

7. Telecommunications - Antenna Components:

Telecommunication equipment relies on precision machining for crafting antenna components from 6061 aluminum, ensuring signal strength and longevity.

8. Sporting Goods - Bicycle Frames:

Within the sporting goods industry, our machining service contributes to the production of bicycle frames, benefitting from the ideal combination of strength and weight offered by 6061 aluminum.

FAQ