Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

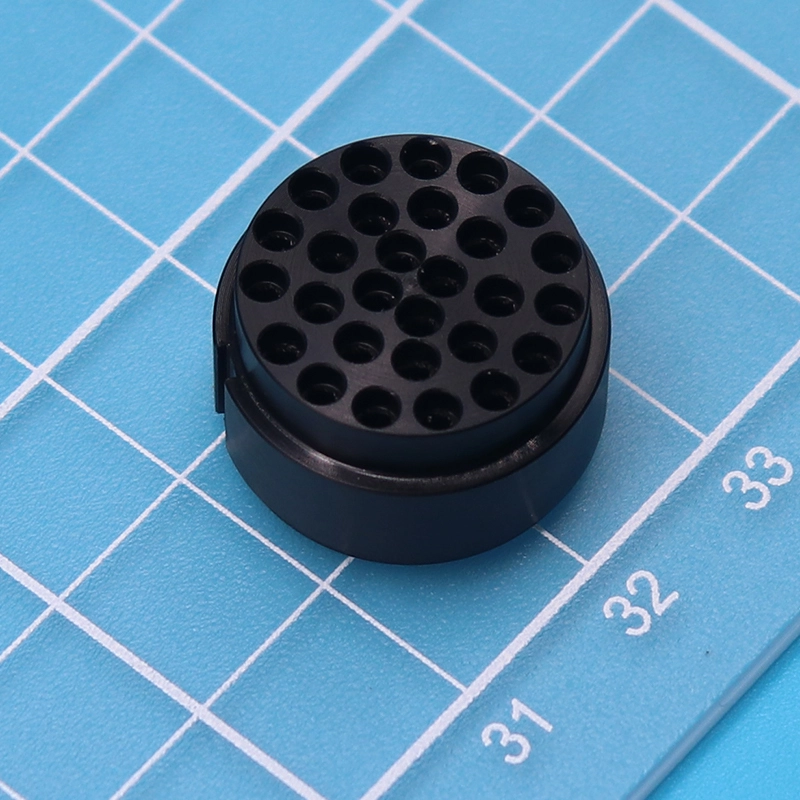

Custom CNC machined plastic parts for Nylon PA6

At RuiXing MFG, we understand the critical importance of precision in CNC machining. Our custom CNC machined plastic parts for nylon PA6 exemplify precision engineering, ensuring that each component meets tight tolerances with consistent accuracy.

Nylon PA6: A Material of Choice

Nylon PA6 stands out for its robust properties, making it an excellent choice for various applications. Its high strength, resilience, and resistance to wear and tear make it suitable for demanding environments. Our CNC machining expertise brings out the best in nylon PA6, providing you with durable and reliable custom parts.

Applications Across Industries

Our CNC plastic parts find applications across a spectrum of industries. Whether it's automotive components, industrial machinery parts, or electronic enclosures, our nylon PA6 parts meet the stringent requirements of diverse sectors. Each component is meticulously crafted to ensure functionality and longevity.

Characteristic

1. Tensile Strength:

- Nylon PA6 exhibits a high tensile strength ranging from 50 to 75 MPa, ensuring robustness and durability in various applications.

2. Flexural Modulus:

- With a flexural modulus between 2,000 and 4,000 MPa, nylon PA6 provides excellent stiffness, making it suitable for components requiring structural integrity.

3. Impact Strength:

- The impact strength of nylon PA6, ranging from 30 to 70 kJ/m², contributes to its ability to withstand sudden forces without undergoing deformation or breakage.

4. Temperature Resistance:

- Nylon PA6 offers thermal stability with a melting point in the range of 220 to 260°C, allowing it to maintain structural integrity under elevated temperatures.

5. Chemical Resistance:

- This material demonstrates good resistance to various chemicals, oils, and solvents, ensuring longevity and reliability in challenging environments.

6. Water Absorption:

- Nylon PA6 has a water absorption rate of around 2-3%, which should be considered in applications where exposure to moisture is a factor.

Advantages:

- Versatility:

Nylon PA6's versatility allows for the production of intricate and custom CNC plastic parts across different industries.

- Mechanical Properties:

Its favorable tensile strength, flexural modulus, and impact strength contribute to the durability and performance of components.

- Chemical Resistance:

The material's resistance to chemicals enhances its suitability for applications exposed to various substances.

- Temperature Stability:

Nylon PA6 maintains structural integrity even under elevated temperatures, expanding its application range.

Disadvantages:

- Water Absorption:

While relatively low, the water absorption property may be a consideration in applications with prolonged exposure to moisture.

Application

1. Automotive Industry:

Custom CNC machined plastic parts for Nylon PA6, such as intake manifolds and engine covers, are widely used in automobiles due to their high strength-to-weight ratio and resistance to chemicals and heat. They contribute to improved engine performance and longevity.

2. Electronics Sector:

In the electronics industry, they like circuit board housings and connectors provide excellent electrical insulation properties and dimensional stability, ensuring reliable performance in various electronic devices.

3. Medical Devices:

Custom CNC plastic parts made from nylon PA6 are extensively

employed in medical devices such as surgical instruments, implantable components, and diagnostic equipment. These parts offer biocompatibility, sterilization resistance, and precision, meeting stringent medical standards.

4. Aerospace Applications:

They play a vital role in aerospace applications, including aircraft interiors, structural components, and satellite systems. Their lightweight nature, high mechanical strength, and resistance to wear make them ideal for aerospace engineering.

5. Consumer Goods:

From sporting equipment like gears and bearings to household appliances like vacuum cleaners and kitchen gadgets, custom CNC plastic parts manufactured from nylon PA6 offer durability, corrosion resistance, and precision, enhancing the performance and lifespan of consumer products.

6. Industrial Machinery:

Custom CNC machined plastic parts for Nylon PA6 find extensive use in industrial machinery such as gears, bearings, and bushings. Their self-lubricating properties, wear resistance, and ability to withstand harsh operating conditions make them indispensable in various manufacturing processes.

FAQ