Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

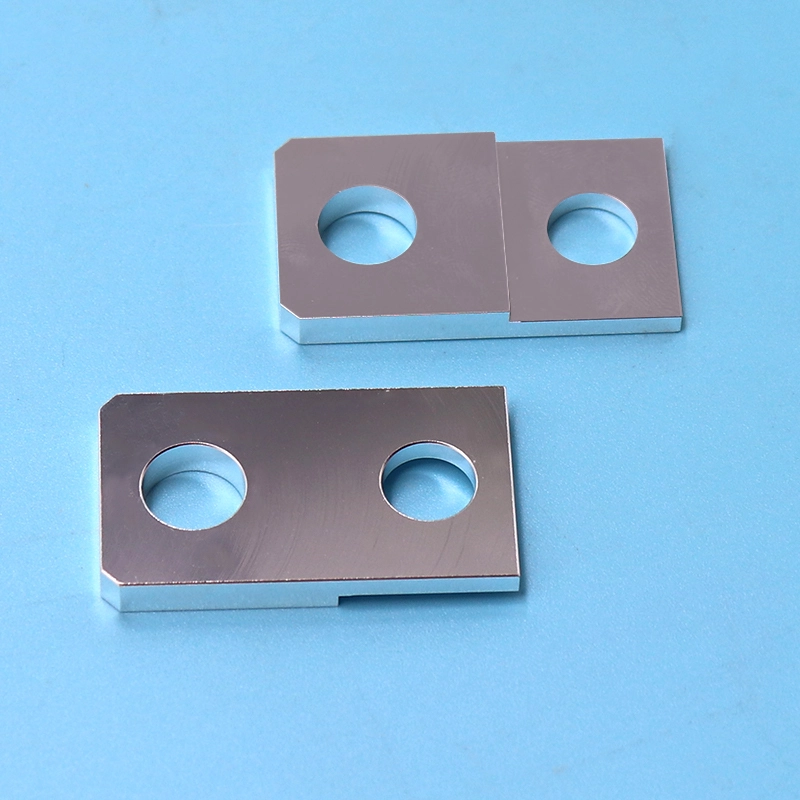

Custom CNC machined CuA1 copper parts with silver plating

CNC machining meets precision in our custom CNC machined CuA1 copper parts with silver plating. Crafted with meticulous attention to detail, our OEM services offer tailored solutions for diverse industries.

CuA1 copper, known for its electrical conductivity and thermal performance, is CNC machined to exact specifications. The silver plating enhances corrosion resistance and ensures longevity. Whether for electrical components, connectors, or specialized parts, our CNC machining expertise delivers quality and reliability.

Characteristic

1. Electrical Conductivity:

CuA1 copper boasts an exceptional electrical conductivity of approximately 58.1 × 10^6 S/m, making it an ideal choice for applications requiring efficient transmission of electric current.

2. Thermal Conductivity:

With a thermal conductivity of around 398 W/(m·K), CuA1 copper efficiently dissipates heat, making it suitable for various thermal management applications.

3. Density:

CuA1 copper has a density of about 8,900 kg/m³, providing a balance between sturdiness and weight, making it applicable in diverse engineering solutions.

4. Melting Point:

The melting point of CuA1 copper is approximately 1,083°C, ensuring stability under high-temperature conditions, crucial for demanding industrial environments.

5. Tensile Strength:

CuA1 copper exhibits a tensile strength of around 240 MPa, providing structural integrity and reliability in various mechanical applications.

6. Yield Strength:

With a yield strength of approximately 200 MPa, CuA1 copper maintains its structural integrity under specific loads, contributing to its longevity.

Advantages:

- Excellent electrical and thermal conductivity.

- Balanced density for structural applications.

- High melting point for stability in elevated temperatures.

- Good tensile and yield strength for mechanical reliability.

Disadvantages:

- Vulnerable to corrosion in certain environments.

- Higher cost compared to other non-copper alternatives.

Application

Automotive Industry:

Custom CNC machined CuA1 copper parts with silver plating find their place in electrical connectors, heat exchangers, and wiring systems due to their excellent conductivity and thermal properties. Silver plating enhances corrosion resistance, making them reliable in challenging automotive environments.

Electronics and Telecommunications:

In electronic devices, the precision of CNC machining is crucial. They serve in circuit boards, connectors, and antennas, ensuring efficient electrical conductivity. Silver plating adds an extra layer of protection against oxidation.

Renewable Energy:

CuA1 copper's conductivity makes it ideal for renewable energy applications. CNC machined parts are used in solar panels, wind turbines, and electrical connections. Silver plating ensures longevity in outdoor settings.

Medical Equipment:

In the medical field, where precision is paramount, custom CNC machined CuA1 copper parts with silver plating play a role in diagnostic equipment, imaging devices, and electronic components. The antimicrobial properties of silver plating contribute to a hygienic environment.

Silver plating

Silver plating is a surface treatment process that involves depositing a thin layer of silver onto the surface of a base material, often copper or other metals, through electroplating. This method enhances the properties of the underlying material and provides several benefits for various applications.

Key Aspects of Silver Plating:

1. Corrosion Resistance:

Silver is known for its excellent corrosion resistance. Silver-plated surfaces are less prone to tarnishing and corrosion, ensuring the longevity and durability of the components.

2. Electrical Conductivity:

Silver is an exceptional conductor of electricity. By silver plating, components gain improved electrical conductivity, making it an ideal choice for applications where efficient electrical transmission is critical.

3. Solderability:

Silver plating enhances solderability, facilitating the soldering process during assembly. This is particularly advantageous in the production of electronic components.

4. Lubricity:

Silver-plated surfaces exhibit good lubricity, reducing friction and wear. This property is beneficial in applications where moving parts require smooth operation.

5. Aesthetics:

Apart from its functional benefits, silver plating provides an aesthetically pleasing finish. This is advantageous when components are visible and contribute to the overall appearance of the product.

Applications of Silver-Plated Components:

1. Electronics:

Silver-plated components are widely used in the electronics industry for connectors, switches, and other critical electrical contacts.

2. Medical Devices:

In medical applications, silver plating is utilized for components that require high biocompatibility and reliability, such as medical connectors and sensors.

3. Aerospace:

Aerospace applications benefit from silver plating due to its electrical conductivity and corrosion resistance, making it suitable for critical components.

FAQ