Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

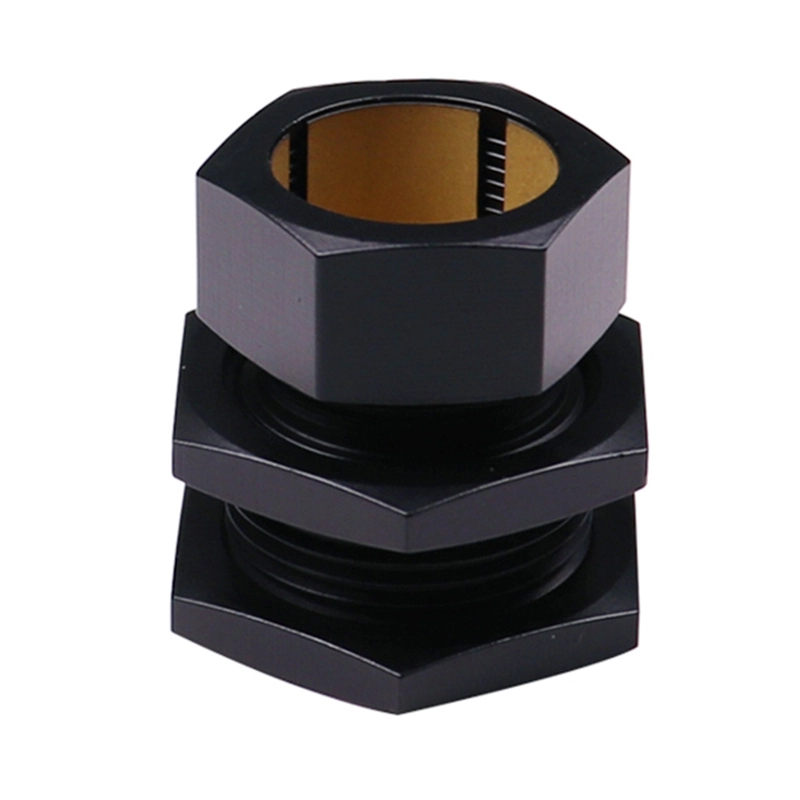

Brass CNC machining parts with teflon coating

Our custom brass CNC machining parts with Teflon coating offer exceptional performance and durability for a wide range of applications. Combining the strength of brass with the low-friction properties of Teflon, these parts deliver superior functionality and reliability.

These brass CNC machining parts with Teflon coating find applications in various industries, including automotive, aerospace, electronics, and machinery. They are commonly used in components such as valves, fittings, connectors, bushings, and seals.

Contact us today to discuss your specific requirements and discover how our parts can elevate your projects.

Understanding Brass CNC Machining Parts with Teflon Coating

Brass CNC machining parts with Teflon coating combine the inherent strength and versatility of brass with the exceptional low-friction properties of Teflon. This powerful combination results in parts that exhibit enhanced durability, improved performance, and extended service life.

Key Features

◎ Low Friction:

The Teflon coating on these parts significantly reduces friction, enabling smooth movement and minimizing wear and tear.

◎ Corrosion Resistance:

The Teflon coating acts as a protective barrier, shielding the brass from corrosive elements and extending the lifespan of the parts.

◎ Wear Resistance:

The Teflon coating enhances the wear resistance of the parts, ensuring they can withstand demanding operating conditions and maintain their performance over time.

◎ Chemical Resistance:

Brass CNC machining parts with Teflon coating exhibit excellent resistance to a wide range of chemicals, making them suitable for applications involving exposure to corrosive substances.

Diverse Applications

◎ Automotive Industry:

These parts find extensive use in automotive applications, including engine components, transmission systems, braking systems, and fuel delivery systems.

◎ Aerospace Industry:

They are utilized in aircraft assemblies, hydraulic systems, landing gear components, and control mechanisms.

◎ Electronics and Electrical Industry:

These parts are employed in connectors, switches, terminals, and other electrical components, ensuring reliable performance and reducing the risk of friction-induced failures.

◎ Machinery and Equipment:

They are crucial in machinery and equipment manufacturing, including pumps, valves, bearings, gears, and actuators.

◎ Medical Devices:

These parts are utilized in medical devices such as surgical instruments, diagnostic equipment, prosthetics, and implants, where low friction and corrosion resistance are essential.

◎ Oil and Gas Industry:

They are employed in valves, fittings, and connectors used in oil and gas exploration, production, and refining processes.

◎ Marine Applications:

These parts find use in marine equipment and systems, including propellers, shafts, couplings, and marine pumps, where corrosion resistance and durability are paramount.

◎ Food Processing Industry:

Brass CNC machining parts with Teflon coating are suitable for food processing equipment, ensuring smooth operation, easy cleaning, and compliance with hygiene standards.

Advantages

◎ Improved Efficiency:

The low friction provided by the Teflon coating reduces energy consumption and enhances overall operational efficiency.

◎ Enhanced Performance:

These parts contribute to smoother operation, reduced noise, and improved precision, resulting in enhanced performance of the machinery or system.

◎ Extended Service Life:

The Teflon coating protects the brass from wear, corrosion, and chemical damage, ensuring the parts have a longer lifespan and require less frequent replacement.

◎ Cost Savings:

By reducing friction-related failures, minimizing downtime, and extending maintenance intervals, these parts offer cost savings in the long run.

FAQ