Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

CNC machining anodized 6061 aluminum assembly service

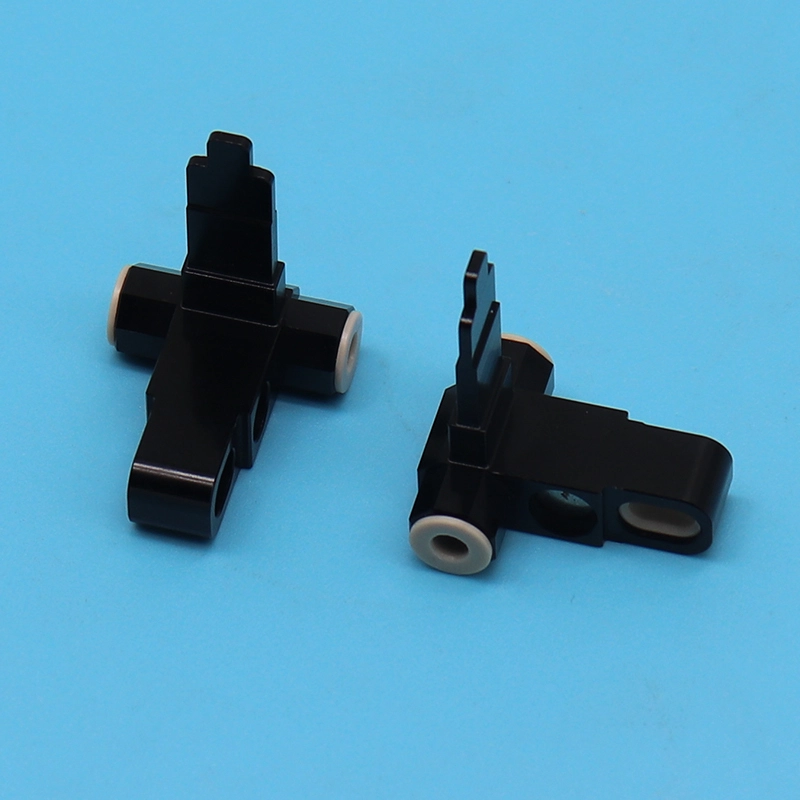

Our CNC machining anodized 6061 aluminum assembly service delivers precision-crafted components tailored to meet the exact specifications of OEM applications.

The anodized finish not only enhances the aesthetic appeal but also provides additional durability, corrosion resistance, and protection against environmental factors.

Our expertise in CNC machining allows us to create intricate assemblies, meeting tight tolerances and intricate design requirements. The 6061 aluminum alloy's exceptional balance of strength and machinability makes it a versatile choice for various industrial applications.

Whether you require components for automotive, aerospace, or electronic applications, our service guarantees reliable and efficient solutions. We prioritize precision, consistency, and adherence to client specifications, ensuring the seamless integration of our components into your projects.

Characteristic

1. Surface Finish Quality:

The anodized finish on our CNC-machined 6061 aluminum components is consistently controlled, providing a surface finish within the range of Ra 0.3-0.5 microns. This guarantees an aesthetically pleasing appearance while maintaining functional integrity.

2. Material Composition Metrics:

Crafted from the resilient 6061 aluminum alloy, the parts boast a balanced combination of material properties. The alloy exhibits a tensile strength of 275 MPa, yield strength of 240 MPa, and a hardness range of 95-97 HRB, ensuring durability and suitability for diverse applications.

3. Anodized Coating Thickness:

The anodized coating thickness on our aluminum parts is precisely controlled, typically ranging from 15 to 20 microns. This thickness ensures optimal durability, corrosion resistance, and longevity in challenging environments.

Advantages:

a. Enhanced Corrosion Resistance:

The anodized coating significantly enhances the corrosion resistance of the 6061 aluminum, making the components suitable for applications exposed to harsh environmental conditions.

b. Improved Aesthetics:

The anodized finish not only protects but also enhances the aesthetics of the components, offering a visually appealing surface with customizable color options.

c. Extended Lifespan:

With tight dimensional tolerances and a robust anodized coating, our CNC-machined 6061 aluminum components exhibit an extended lifespan, reducing the need for frequent replacements.

Disadvantages:

a. Limited Coating Thickness Range:

While the anodized coating thickness is precise, it is limited to a specific range. This may restrict applications requiring thicker coatings for specialized needs.

Application

1. Aerospace: Aircraft Fuselage Components

In the aerospace sector, our CNC-machined and anodized 6061 aluminum parts are employed in crafting fuselage components. The anodized finish ensures corrosion resistance, while CNC precision guarantees tight tolerances vital for aerospace structural integrity.

2. Automotive: Electric Vehicle Battery Housings

Within the automotive industry, our service is utilized for manufacturing electric vehicle battery housings. The anodized 6061 aluminum provides thermal efficiency and corrosion resistance, safeguarding vital components in electric vehicles.

3. Medical: Imaging Equipment Mounting Systems

Precision is paramount in the medical field. Our CNC-machined anodized aluminum components are integral in crafting mounting systems for medical imaging equipment, ensuring stability, durability, and resistance to sterilization processes.

FAQ