Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

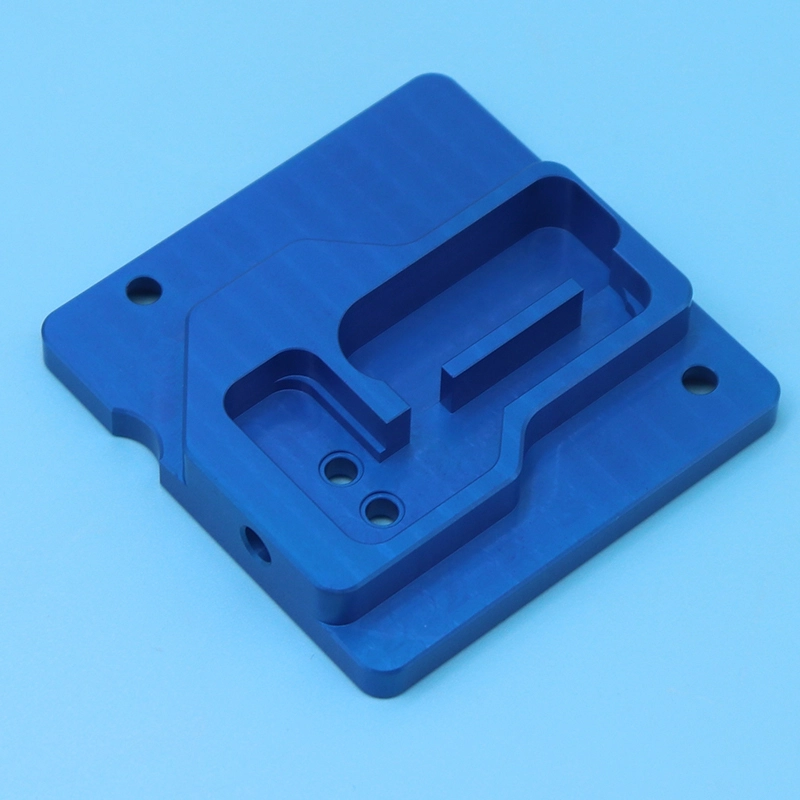

CNC machined 2017 aluminum parts

The 2017 aluminum alloy boasts remarkable strength-to-weight ratio, corrosion resistance, and machinability. This makes our parts popular in industries such as aerospace, automotive, electronics, and beyond.

Discover the precision and versatility of CNC machined 2017 aluminum parts, and their exceptional strength, lightweight design, and superior performance.

Product Description

Discover the precision and versatility of CNC machined 2017 aluminum parts, and their exceptional strength, lightweight design, and superior performance.

◎ Properties of 2017 Aluminum Alloy:

1. Strength:

2017 aluminum alloy exhibits excellent strength, making it suitable for applications requiring robust components.

2. Lightweight:

Despite its strength, 2017 aluminum is relatively lightweight, contributing to improved fuel efficiency and overall weight reduction in various industries.

3. Corrosion Resistance:

The alloy possesses good resistance to corrosion, making it suitable for applications in harsh environments.

4. Machinability:

2017 aluminum alloy is highly machinable, allowing for efficient production and intricate designs.

◎ Comparison with Other Aluminum Alloys:

1. 2017 vs. 6061 Aluminum:

While 6061 aluminum offers better corrosion resistance, 2017 aluminum provides higher strength and machinability.

2. 2017 vs. 7075 Aluminum:

Compared to 7075 aluminum, 2017 alloy has lower strength but superior machinability.

Advantages & Disadvantages

Advantages

◎ Strength-to-Weight Ratio:

2017 aluminum parts offer an excellent strength-to-weight ratio, making them suitable for weight-sensitive applications without compromising structural integrity.

◎ Machinability:

The high machinability of 2017 aluminum simplifies the manufacturing process, resulting in reduced production time and costs.

◎ Corrosion Resistance:

The alloy's corrosion resistance ensures the longevity and durability of CNC machined 2017 aluminum parts.

Disadvantages

◎ Lower Strength Compared to Some Alloys:

While 2017 aluminum alloy is strong, it may not match the strength of certain other aluminum alloys, such as 7075.

Detailed Application Scenarios

◎ Aerospace Industry:

1. Aircraft Components:

CNC machined 2017 aluminum parts find applications in aircraft structural components, such as wing ribs and fuselage frames, due to their strength and lightweight nature.

2. Aerospace Fasteners:

The alloy's strength and corrosion resistance make it suitable for aerospace fasteners, ensuring secure connections.

◎ Automotive Industry:

1. Engine Components:

They are used in engine blocks, pistons, and cylinder heads, benefiting from their strength and thermal conductivity.

2. Suspension Systems:

The lightweight and durable properties of 2017 aluminum make it ideal for manufacturing suspension components, reducing unsprung weight and improving handling.

◎ Electronics Industry:

1. Heat Sinks:

CNC machined 2017 aluminum heat sinks offer efficient heat dissipation for electronic devices, ensuring optimal performance and reliability.

2. Enclosures:

The corrosion resistance and machinability of 2017 aluminum make it suitable for electronic enclosures, protecting sensitive components.

◎ Industrial Machinery:

1. Hydraulic Systems:

CNC machined 2017 aluminum parts are utilized in hydraulic systems, benefiting from their strength, corrosion resistance, and machinability.

2. Conveyor Systems:

The lightweight nature of 2017 aluminum allows for the construction of efficient and durable conveyor systems in various industries.

FAQ