Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

Industrial Parts CNC Milling - - Ruixing

Company Advantages

· The design concept of Ruixing industrial parts is based on modern green style.

· Every stage of the production process is strictly monitored to ensure the quality of this product.

· Good service of Ruixing has attracted more and more customers.

Characteristic

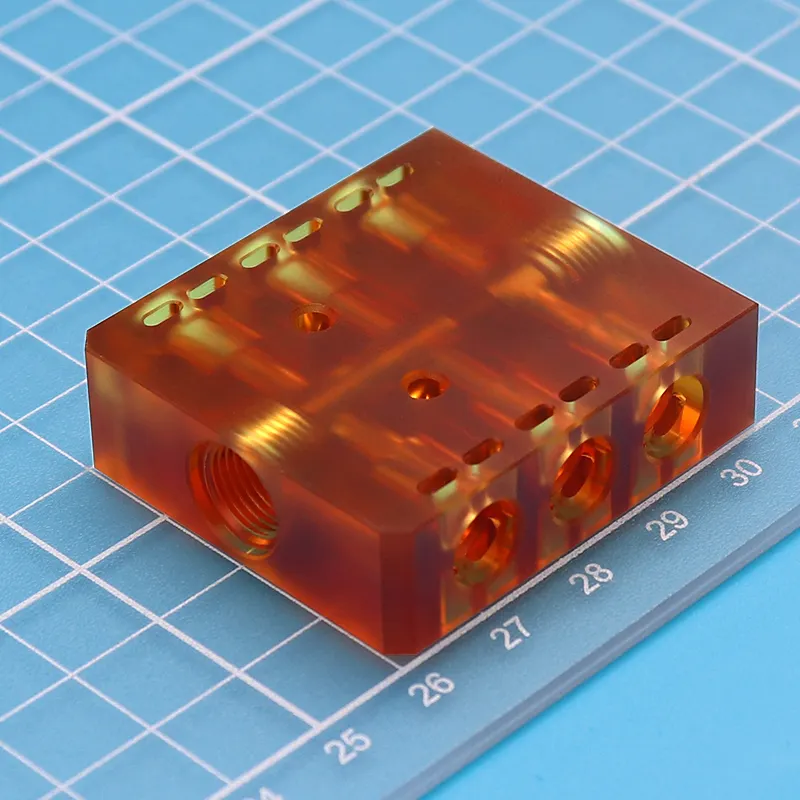

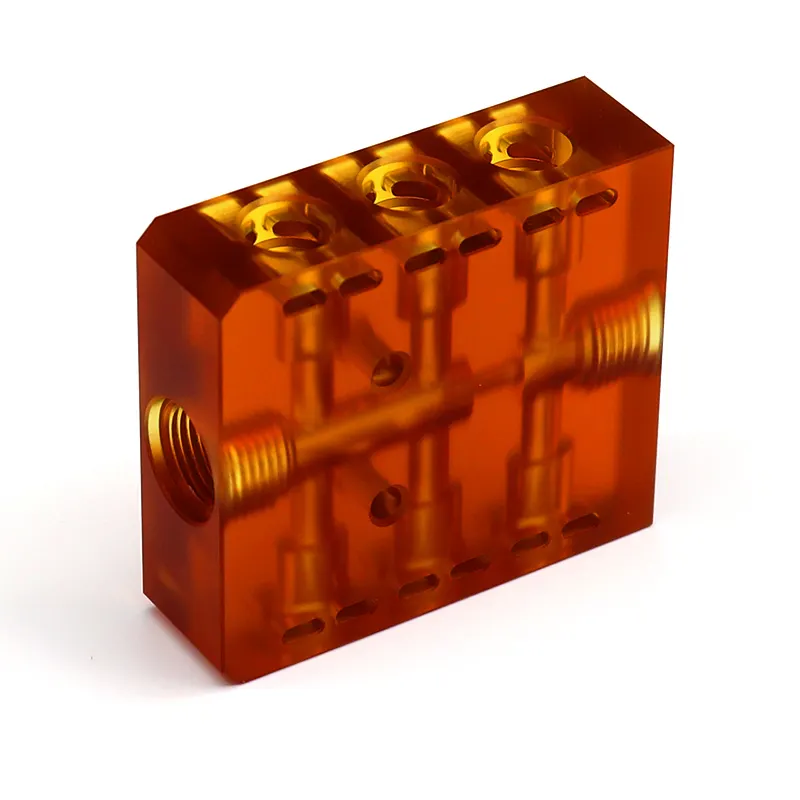

PEI (Polyetherimide) is a high-performance engineering plastic known for its exceptional thermal stability, mechanical strength, and chemical resistance. These characteristics make it an excellent choice for precision custom CNC machined PEI plastic manifolds. Below are the detailed properties, advantages, and disadvantages of PEI:

Characteristics of PEI (Polyetherimide):

1. Thermal Stability:

- Glass Transition Temperature (Tg):

Approximately 217°C (423°F).

- Continuous Use Temperature:

Up to 170°C (338°F).

- Heat Deflection Temperature (HDT):

200°C (392°F) at 1.8 MPa.

2. Mechanical Strength:

- Tensile Strength: 110 MPa.

- Flexural Strength: 170 MPa.

- Modulus of Elasticity: 3.6 GPa.

3. Chemical Resistance:

- Resistant to hydrocarbons, alcohols, and halogenated solvents.

- Limited resistance to strong acids and bases.

4. Electrical Properties:

- Dielectric Strength: 830 V/mil.

- Volume Resistivity: 1.0 × 10^17 ohm-cm.

5. Flammability:

- UL94 V-0 rating, indicating good flame retardancy.

Advantages of PEI:

1. High Thermal Stability:

- Suitable for applications involving high temperatures without losing mechanical integrity.

2. Excellent Mechanical Properties:

- High tensile and flexural strength provide durability and resistance to deformation.

3. Chemical Resistance:

- Good resistance to a variety of chemicals, making it suitable for harsh environments.

4. Electrical Insulation:

- Superior dielectric properties make it ideal for electrical and electronic components.

5. Flame Retardancy:

- Inherent flame resistance enhances safety in applications requiring high fire safety standards.

Disadvantages of PEI:

1. Cost:

- Higher material cost compared to other engineering plastics.

2. Machining Challenges:

- Requires precise machining techniques due to its hardness and brittleness.

3. Limited Resistance to Acids and Bases:

- Not suitable for environments with strong acids and bases.

4. Moisture Absorption:

- Can absorb moisture, potentially affecting dimensional stability in humid conditions.

Application

Precision Custom CNC Machined PEI Plastic Manifolds are utilized across various industries due to their exceptional thermal stability, mechanical strength, and resistance to chemical corrosion. These manifolds are specifically designed to optimize the performance of fluid and gas systems, making them indispensable in multiple sectors.

1. Medical Industry:

In the medical field, they are essential components in diagnostic equipment and laboratory instruments. For instance, they are used in fluidic systems of blood analyzers and other diagnostic devices, ensuring accurate and reliable fluid management.

2. Aerospace Industry:

In aerospace applications, they are used in fuel management systems and hydraulic control systems. Their ability to withstand high temperatures and mechanical stress makes them suitable for critical aerospace components, such as fuel distribution systems in aircraft engines.

3. Chemical Processing:

In the chemical processing industry, they are employed in chemical reactors and processing equipment. Their resistance to a wide range of chemicals makes them ideal for use in systems that handle aggressive substances, ensuring longevity and reliability.

4. Semiconductor Manufacturing:

The semiconductor industry uses them in etching and deposition equipment. Precision machining is crucial here to maintain the high standards required for semiconductor fabrication, ensuring consistent performance and minimal contamination.

5. Food and Beverage Industry:

In food and beverage processing, they are used in dispensing and packaging equipment. Their ability to handle a range of temperatures and resist chemical cleaning agents makes them suitable for maintaining hygiene and operational efficiency.

6. Pharmaceutical Industry:

Pharmaceutical manufacturing relies on them in drug formulation and packaging machinery. Precision CNC machining ensures that these components meet the necessary standards for drug safety and efficacy, supporting consistent and reliable production processes.

FAQ

Company Features

· Doing well in R&D and production of industrial parts, Shenzhen Ruixing Precision MFG has gained a high reputation at home and oversea market.

· Our company brings together a group of talented committed and engaged employees. Their skills, knowledge, attitude, and creativity ensure that we continue to deliver great service and positive outcomes for our clients.

· We can do all that our customers want us to do for industrial parts. Welcome to visit our factory!

Application of the Product

The industrial parts produced by Ruixing is widely used in industry.

Based on customers' specific situations and needs, Ruixing provides comprehensive and reasonable solutions.

Product Comparison

The main differences between Ruixing's industrial parts and similar products are as follows.