Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

Cnc Machining Plastic None Wholesale - Ruixing

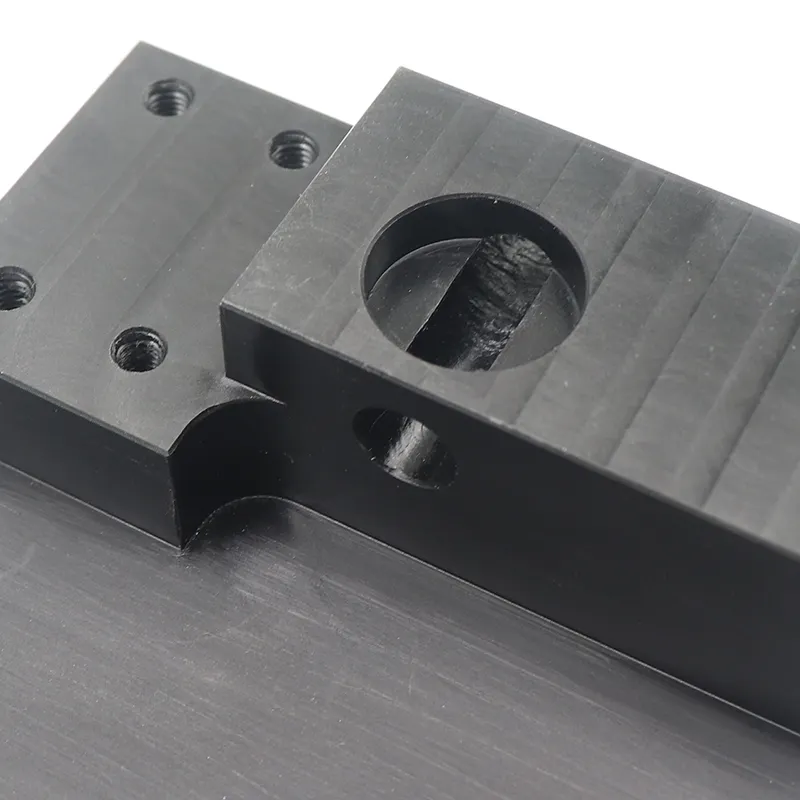

Feature

1. Material Characteristics:

Nylon PA6, a type of polyamide, exhibits specific numerical parameters:

- Density: 1.14 g/cm³

- Melting Point: 220°C (428°F)

- Tensile Strength: 80 MPa

- Elongation at Break: 250%

- Hardness (Rockwell R): 118

2. Advantages:

- Mechanical Strength:

Nylon PA6 boasts high tensile strength, providing durability in components.

- Chemical Resistance:

Resistant to various chemicals, enhancing suitability for diverse environments.

- High Elongation:

Exhibits notable elongation at break, making it flexible and impact-resistant.

- Low Friction Coefficient:

Possesses a low coefficient of friction, suitable for applications requiring smooth movements.

3. Disadvantages:

- Moisture Absorption:

Nylon PA6 is hygroscopic, absorbing moisture, potentially affecting mechanical properties.

- UV Sensitivity:

Not UV resistant, limiting outdoor applications.

- Thermal Expansion:

Shows sensitivity to thermal expansion, requiring consideration in specific applications.

4. Challenges in CNC Machining:

Precision machining of Nylon PA6 presents specific challenges:

- Tool Wear:

The abrasiveness of Nylon PA6 may lead to accelerated tool wear.

- Chip Control:

Proper chip control is crucial due to the material's tendency to form long, stringy chips.

- Thermal Considerations:

Managing thermal effects during machining to maintain dimensional accuracy.

Application

1. Automotive Sector:

Custom CNC machined Nylon PA6 parts find application in the automotive industry, contributing to the production of components like gears, bushings, and connectors. Their durability and resistance to wear make them suitable for enhancing the performance and lifespan of automotive assemblies.

2. Electronic Components:

In the electronics industry, these CNC-machined parts are utilized for producing casings, insulators, and connectors. The electrical insulating properties of Nylon PA6 make it a reliable choice for electronic applications.

3. Aerospace Precision:

For OEM CNC machining in the aerospace sector, they play a crucial role. Their lightweight nature and dimensional stability make them suitable for precision applications in aircraft and aerospace equipment.

4. Medical Equipment Manufacturing:

They contribute to the production of medical devices, providing biocompatible and durable solutions. Their ability to meet stringent tolerances makes them ideal for critical components in the medical field.

5. Industrial Machinery Customization:

In the realm of industrial machinery, these CNC-machined parts are employed for custom components, ensuring efficiency and reliability. Nylon PA6's resistance to chemicals and durability make it suitable for demanding industrial environments.

6. Consumer Goods Production:

Custom CNC machined Nylon PA6 parts find applications in the manufacturing of consumer goods, such as appliances and tools, where precision and durability are essential.

7. Fluid Handling Systems:

Due to its resistance to chemicals and wear, Nylon PA6 is a preferred choice for CNC-machined parts in fluid handling systems, ensuring reliability in pipes, valves, and connectors.

FAQ

Company Advantages

· The production of Ruixing cnc machining plastic strictly adheres to the latest international standards.

· Our qualified and experienced staff strictly follows the quality control system.

· Shenzhen Ruixing Precision MFG has formed perfect quality assurance system and production guarantee system.

Company Features

· Ruixing is skilled at manufacturing cnc machining plastic.

· Our factory has a standard workshop that is built according to the stipulated requirements. The workshop has reasonable arranged production lines that guarantee smooth, ordered, and efficient production.

· We have drawn up a series of major challenges - going beyond zero environmental impact to deliver positive environmental benefits.

Application of the Product

Ruixing's cnc machining plastic has been widely used in many industries.

Ruixing is dedicated to providing professional, efficient and economical solutions for customers, so as to meet customers' needs to the greatest extent.