Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

Custom Precision Sheet Metal Bending Audio Equipment Panel With Powder Coating

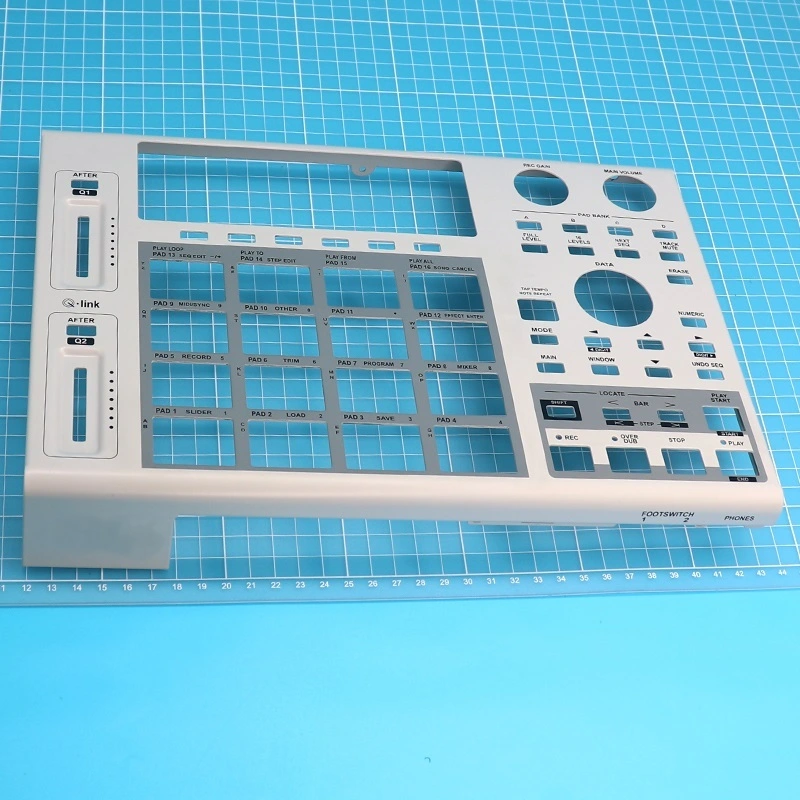

At Ruixing MFG, we offer custom precision sheet metal bending for audio equipment panels with powder coating. Our panels are engineered to meet the precise requirements of audio equipment manufacturers, ensuring durability and a professional finish. Each panel is crafted to exact specifications, using high-quality materials to provide reliable and consistent performance.

Our sheet metal bending process guarantees accuracy and uniformity, essential for maintaining the integrity and functionality of audio equipment. The powder coating adds an extra layer of protection, enhancing the panel’s resistance to wear and corrosion. This treatment not only improves the panel's lifespan but also provides a clean, polished appearance suitable for high-end audio equipment.

By choosing our custom precision sheet metal bending and powder coating services, you can trust that your audio equipment panels will meet industry standards and deliver reliable results. Our focus on quality and precision ensures that each panel we produce aligns with your specific needs and requirements.

Characteristic

304 stainless steel is widely used in custom precision sheet metal bending for audio equipment panels due to its balanced properties. Here are the detailed characteristics and numerical parameters of 304 stainless steel:

1. Chemical Composition:

- Carbon (C): ≤ 0.08%

- Manganese (Mn): ≤ 2.00%

- Phosphorus (P): ≤ 0.045%

- Sulfur (S): ≤ 0.03%

- Silicon (Si): ≤ 0.75%

- Chromium (Cr): 18.00-20.00%

- Nickel (Ni): 8.00-10.50%

- Nitrogen (N): ≤ 0.10%

2. Mechanical Properties:

- Tensile Strength: 505 MPa (73,200 psi)

- Yield Strength: 215 MPa (31,200 psi)

- Elongation: 40%

- Hardness (Brinell): 201 HB

3. Physical Properties:

- Density: 7.93 g/cm³

- Melting Point: 1400-1450°C (2552-2642°F)

- Thermal Conductivity: 16.2 W/m·K at 100°C

- Specific Heat: 500 J/kg·K

- Electrical Resistivity: 0.72 µΩ·m at 20°C

Advantages:

1. Corrosion Resistance:

304 stainless steel exhibits excellent resistance to a wide range of atmospheric environments and many corrosive media.

2. Formability:

This material can be easily formed into various shapes and is suitable for welding.

3. Hygienic:

It is easy to clean, making it ideal for applications requiring high sanitation standards.

4. Strength:

Good mechanical properties provide a balance between strength and formability.

Disadvantages:

1. Cost:

304 stainless steel can be more expensive than other steel grades.

2. Work Hardening:

It tends to work-harden, which can make machining more difficult.

3. Temperature Limitations:

While it has good oxidation resistance, it is not suitable for continuous use at high temperatures above 800°C (1472°F).

Applications of Sheet Metal Bending Panel

Custom precision sheet metal bending with powder coating finds versatile applications across various industries, enhancing the functionality and durability of critical components.

- In the automotive sector, these panels are integral to dashboard assemblies, providing structural integrity and a polished finish. They ensure the precise integration of audio control interfaces and display screens, contributing to a seamless user experience.

- In the aerospace industry, these panels serve as protective covers for avionics systems, offering resistance to environmental factors and maintaining reliability during flight operations. Their precision manufacturing ensures compatibility with complex cockpit layouts and instrument panels, meeting stringent safety and performance standards.

Moreover, in the medical equipment field, these panels are utilized in diagnostic devices where precision and hygiene are paramount. The powder coating enhances their resistance to sterilization processes and chemical exposure, prolonging their operational life and maintaining sanitary conditions essential for medical environments.

Across all applications, our custom precision sheet metal bending and powder coating services ensure components meet exacting specifications, delivering durability, functionality, and aesthetic appeal tailored to specific industry needs.

Surface Finishing: Powder Coating

Powder coating is a widely utilized finishing process that involves applying a dry, powdered substance to a surface, which is then cured under heat to form a solid, durable coating. This method offers several advantages over traditional liquid painting techniques, making it a popular choice in various industries.

1. Types of Powder Coatings:

- Thermoplastic: Can be melted and reshaped, providing flexibility and reusability.

- Thermoset: Forms irreversible bonds upon curing, offering high resistance to heat and chemicals.

2. Application Process:

- Preparation: The surface is cleaned and pre-treated to ensure proper adhesion.

- Application: The powder is electrostatically charged and sprayed onto the grounded surface.

- Curing: The coated item is heated in an oven, causing the powder to melt and form a uniform, solid layer.

3. Advantages:

- Durability: Provides a tough, long-lasting finish resistant to chipping, scratching, and fading.

- Environmentally Friendly: Contains no solvents, releasing minimal volatile organic compounds (VOCs) into the atmosphere.

- Efficiency: Overspray can be collected and reused, reducing waste.

4. Common Applications:

- Automotive: Used for wheels, bumpers, and various components for its resistance to road wear.

- Appliances: Applied to household appliances for a durable, attractive finish.

- Architecture: Utilized in outdoor structures and furniture for its weather-resistant properties.

FAQ