Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

Swiss-type lathe parts manufacturers

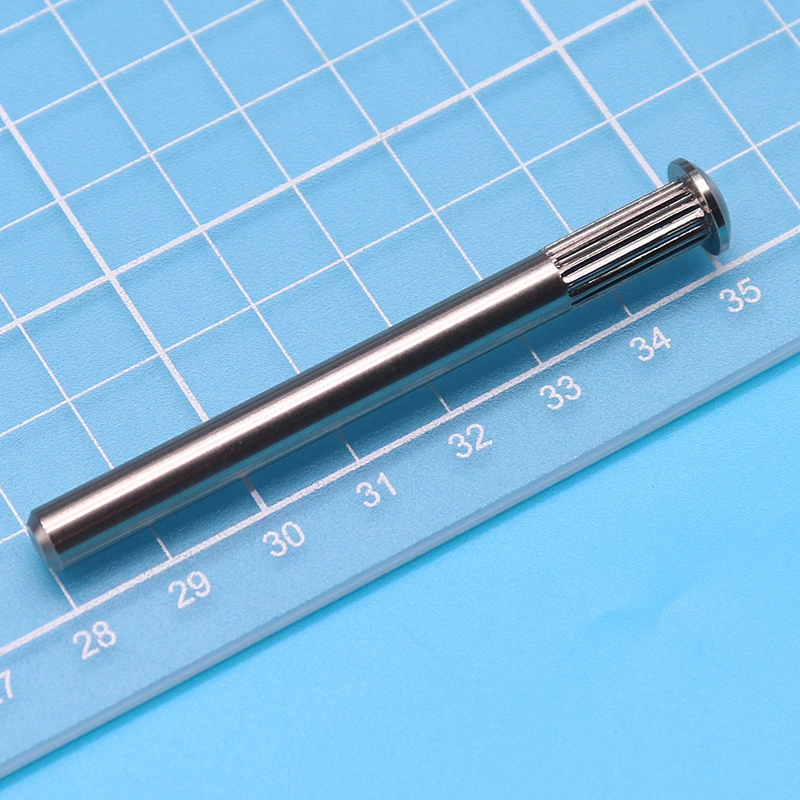

Swiss-type lathes are highly specialized machines capable of producing precision parts for various industries, including automotive, medical, and electronics. These machines excel at manufacturing small, intricate components that require tight tolerances and exceptional surface finishes. Typical parts include screws, pins, bushings, and miniature shafts, often used in demanding environments.

Manufacturers using Swiss-type lathes benefit from the ability to process complex parts from a range of materials, including titanium, brass, aluminum, and engineering plastics. This machining method is especially effective for components requiring deep drilling, fine threading, and detailed external geometries.

Description

Swiss-type lathes are highly specialized machines capable of producing precision parts for various industries, including automotive, medical, and electronics. These machines excel at manufacturing small, intricate components that require tight tolerances and exceptional surface finishes. Typical parts include screws, pins, bushings, and miniature shafts, often used in demanding environments.

Manufacturers using Swiss-type lathes benefit from the ability to process complex parts from a range of materials, including titanium, brass, aluminum, and engineering plastics. This machining method is especially effective for components requiring deep drilling, fine threading, and detailed external geometries.

Applications

Swiss-type lathe parts manufacturers serve a wide range of industries, providing essential components for precise and intricate applications. In the medical sector, Swiss-type lathes are used to produce critical components like bone screws, dental implants, and surgical instruments. These parts require high precision and tight tolerances to ensure the safety and efficacy of medical procedures.

◎ Automotive:

In the automotive industry, manufacturers use Swiss-type lathes to create small but vital components such as valve stems, fuel injector nozzles, and transmission pins. These parts are essential for engine performance, safety features, and overall vehicle functionality.

◎ Aerospace:

The aerospace industry also benefits from Swiss-type machining for parts such as electrical connectors, sensors, and fasteners. These parts are often made from materials like titanium and stainless steel, providing strength and durability while maintaining lightweight properties essential to aerospace designs.

◎ Electronics:

In the electronics industry, Swiss-type lathe manufacturers produce miniature connectors, pins, and contacts for various electronic devices, including mobile phones, computers, and precision instruments.

Swiss-type lathe manufacturers deliver accurate, reliable components that support high-precision applications across multiple sectors, contributing to the overall performance and reliability of final products.

FAQ