Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

Sheet Metal Bending Company Sheet Metal Bending Parts Wholesale - Ruixing

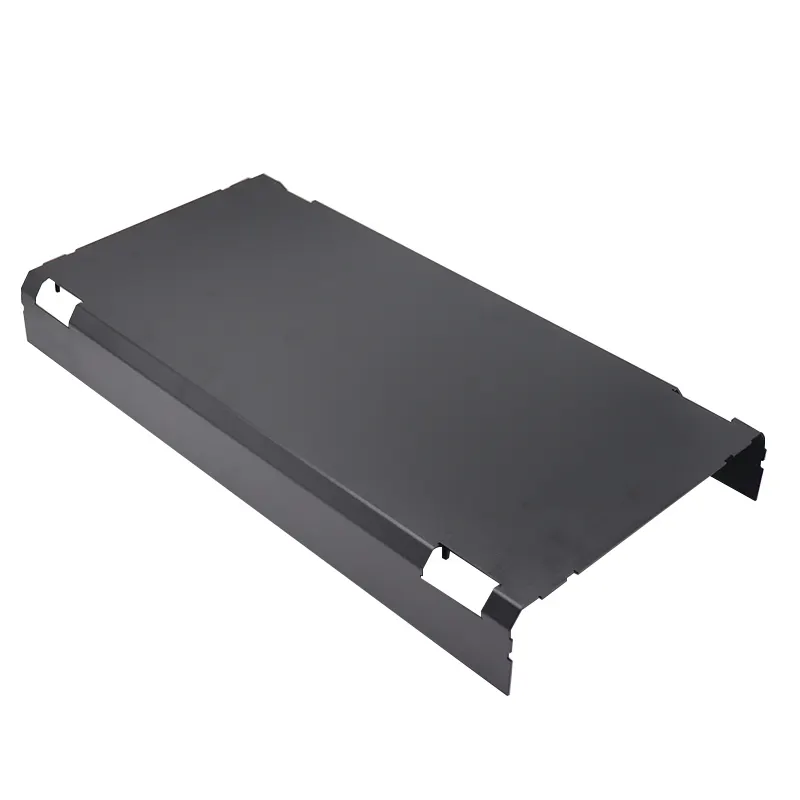

Product details of the sheet metal bending company

Product Information

Continuously improved management system makes sure the production process of Ruixing sheet metal bending company runs smoothly and efficiently. The product is of high quality and can withstand stringent quality and performance tests. Complete sheet metal bending company test machine provides strong assurance for the stable quality.

Characteristic

In the domain of precision manufacturing, the characteristics of Sheet Metal Bending and Laser Cutting for aluminum parts are pivotal for achieving accurate and customized components.

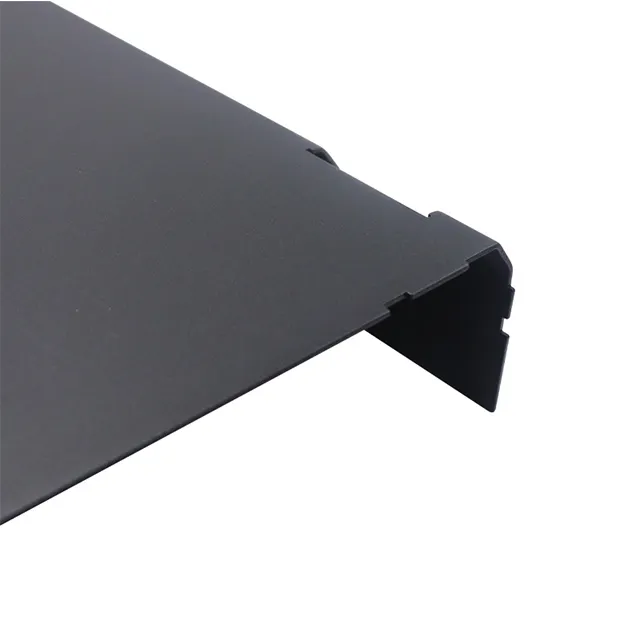

1. Material Thickness (Bending):

- Bending is adept at handling aluminum sheets with thickness ranging from 0.5mm to 6mm.

2. Bend Angle Tolerance (Bending):

- Precision bending allows for achieving bend angle tolerances within ±0.5 degrees.

3. Laser Power (Laser Cutting):

- Laser Cutting effectively processes aluminum sheets with a thickness range of 0.1mm to 12mm.

4. Cutting Speed (Laser Cutting):

- High cutting speeds of up to 2.5 meters per minute ensure efficiency and productivity.

5. Minimum Feature Size (Laser Cutting):

- Laser Cutting achieves intricate details with a minimum feature size as small as 0.2mm.

Advantages:

1. Precision and Accuracy:

- Achieves high precision in bending angles and intricate cuts with laser technology.

2. Versatility in Material Thickness:

- Adaptable to a wide range of aluminum sheet thicknesses for diverse applications.

3. Intricate Detailing:

- Laser Cutting allows for the creation of intricate patterns and small features.

Processing Challenges in CNC Machining:

1. Tool Wear (Bending):

- Continuous bending may lead to tool wear, necessitating regular maintenance.

2. Material Distortion (Bending):

- The bending process may induce material distortion, requiring careful planning.

3. Heat-Affected Zone (Laser Cutting):

- Laser Cutting generates heat, potentially affecting the material around the cut.

4. Edge Quality (Laser Cutting):

- Achieving optimal edge quality demands fine-tuning of laser parameters.

Application

1. Electronics Industry:

Our precision-crafted aluminum components find applications in the electronics sector, where intricate designs and precise dimensions are crucial for components like casings, brackets, and panels.

2. Automotive Sector:

Sheet Metal Bending and Laser Cutting play a vital role in the automotive industry, providing accurate and durable aluminum parts for various applications, including chassis components, brackets, and interior fittings.

3. Aerospace Engineering:

In aerospace applications, where lightweight yet robust materials are essential, our CNC-machined aluminum parts serve in critical components such as structural elements, brackets, and enclosures.

4. Telecommunications:

The telecommunications sector benefits from our precise aluminum components for enclosures, mounting brackets, and specialized parts, ensuring reliable performance and longevity.

5. Medical Equipment:

Precision is paramount in medical equipment, and our CNC-machined aluminum parts contribute to the manufacturing of components for diagnostic devices, support structures, and enclosures.

6. Renewable Energy:

As the demand for sustainable energy solutions grows, our CNC-machined aluminum parts find application in renewable energy systems, including solar panel mounting brackets and support structures.

7. Industrial Machinery:

Sheet Metal Bending and Laser Cutting are integral in producing components for various industrial machinery, such as frames, panels, and support structures, ensuring durability and reliability.

8. Consumer Goods:

From household appliances to recreational equipment, our precision aluminum components contribute to the production of aesthetically pleasing and functional consumer goods.

Process

1. Bending:

- Secure the sheet or plate material into the CNC bending machine.

- Program the machine with precise bending angles and dimensions.

- Activate the bending machine to form the material into the desired shape.

- Inspect the bent component for accuracy and quality.

2. Laser Cutting:

- Secure the material to the CNC machining bed.

- Program the laser cutting machine with the specific design or pattern.

- Initiate the laser cutting process, where the laser beam precisely cuts through the material.

- Conduct a thorough quality check on the cut components.

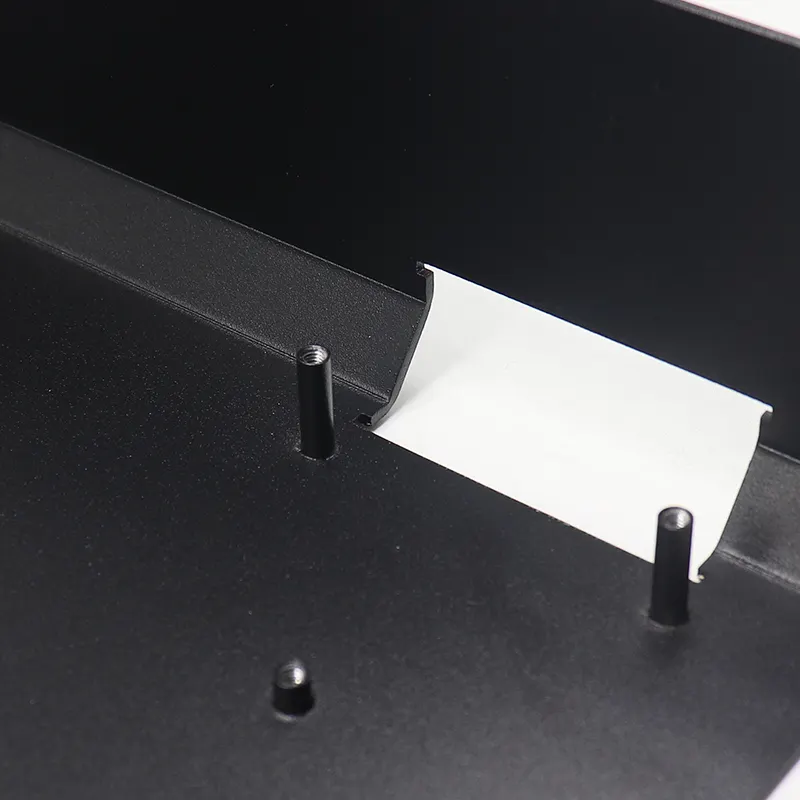

3. Riveting:

- Align the components to be joined securely.

- Select the appropriate rivet type and size.

- Introduce the rivet into the prepared holes.

- Employ a CNC riveting machine to compress and secure the rivet, forming a durable connection.

- Inspect the riveted assembly for structural integrity.

FAQ

Company Feature

• Apart from high-level production talents, our company employs a number of industry-leading experts to guide our daily production management for the products. It provides a strong guarantee for the quality of our products.

• With the reasonable price and high quality, our products are favored by domestic and foreign customers.

• Ruixing always sticks to the tenet that we serve customers wholeheartedly and promotes the healthy and optimistic brand culture. We are committed to providing professional and comprehensive services.

If you would like to purchase our products, please contact us as soon as possible.