Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

Ruixing Sheet Metal Fabrication Services Price List

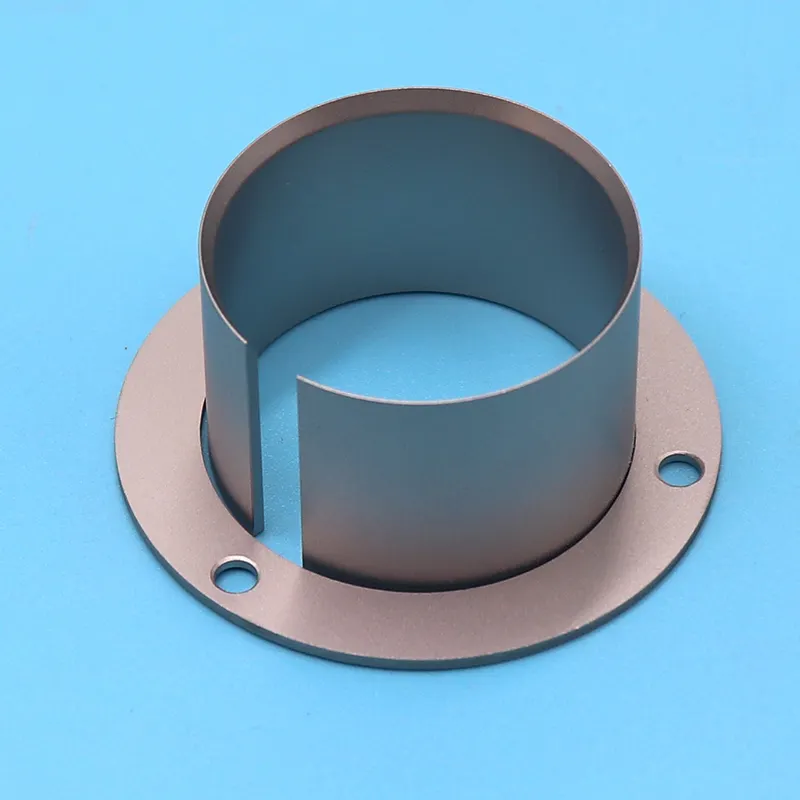

Product details of the sheet metal fabrication services

Product Overview

The creative design of Ruixing sheet metal fabrication services receives positive market responses. The product has been tested for many times under the rigorous quality control system. Shenzhen Ruixing Precision MFG can ensure the fastest and most accurate delivery date for sheet metal fabrication services.

Product Description

Compared with the same kind of products in the industry, sheet metal fabrication services has the following highlights due to the better technical capability.

Characteristic

1. Weldability Parameters:

- 304 stainless steel exhibits excellent weldability, allowing for a variety of welding methods such as arc welding, resistance welding, and gas welding.

- Welding current: 100-120 AC or 100-160 DC (amperes)

- Shielding gas: Argon or a mixture of argon and hydrogen

2. Heat Affected Zone (HAZ) Considerations:

- The HAZ of 304 stainless steel during welding is relatively small, minimizing the risk of sensitization and corrosion issues.

- Preheating is generally not required for thin sections, but it may be beneficial for thicker materials.

3. Post-Weld Annealing:

- Annealing after welding helps restore corrosion resistance and mechanical properties.

- Temperature: 1,010-1,120°C (1,850-2,050°F) for 30 minutes per 25 mm thickness.

4. Advantages of 304 Stainless Steel Welding:

- Corrosion Resistance: 304 stainless steel maintains corrosion resistance even after welding.

- Versatility: Suitable for a wide range of applications due to its compatibility with various fabrication processes.

- Aesthetics: Provides an attractive, polished appearance after welding.

5. Disadvantages of 304 Stainless Steel Welding:

- Sensitization: Prolonged exposure to elevated temperatures can lead to sensitization, reducing corrosion resistance.

- Hot Cracking: Susceptible to hot cracking in specific welding conditions, especially with high sulfur content.

Application

1. Exhaust Manifold Integration:

Precision stainless steel welding, coupled with CNC machining, is instrumental in crafting automotive exhaust manifolds. This synergy ensures precise fitment, optimal performance, and longevity in high-temperature environments.

2. Customized Engine Brackets:

In the automotive industry, CNC machining and precision welding collaboratively create customized stainless steel engine brackets. These components, critical for engine stability, demand meticulous fabrication to meet OEM standards.

3. Fuel Injector Mounts:

The integration of CNC-machined details with precision welding is evident in the fabrication of stainless steel mounts for fuel injectors. This process guarantees a secure and durable placement of critical engine components.

4. Chassis Reinforcement Components:

Precision welding, complemented by CNC machining, is employed in the production of stainless steel components for reinforcing automotive chassis. The result is enhanced structural integrity and safety features.

FAQ

Company Information

Shenzhen Ruixing Precision MFG(Ruixing) mainly supplies CNC Machining Services,Sheet Metal Fabrication. Our company always carries forward our enterprise spirit of 'dedication, collaboration and innovation'. During business operations, we pay great attention to people and quality and we also advocate integrity management. Based on that, we seize opportunities and meet challenges. With advanced science and technology and good brand advantages, we strive to create a leading brand and become a leader within the industry. Our company has a large number of talented people, and lots of highly educated, experienced and innovative employees, which provides a strong backing for our development. With professional service spirit, Ruixing always provides customers with reasonable and efficient one-stop solutions.

All walks of life are welcomed to visit and negotiate.