Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

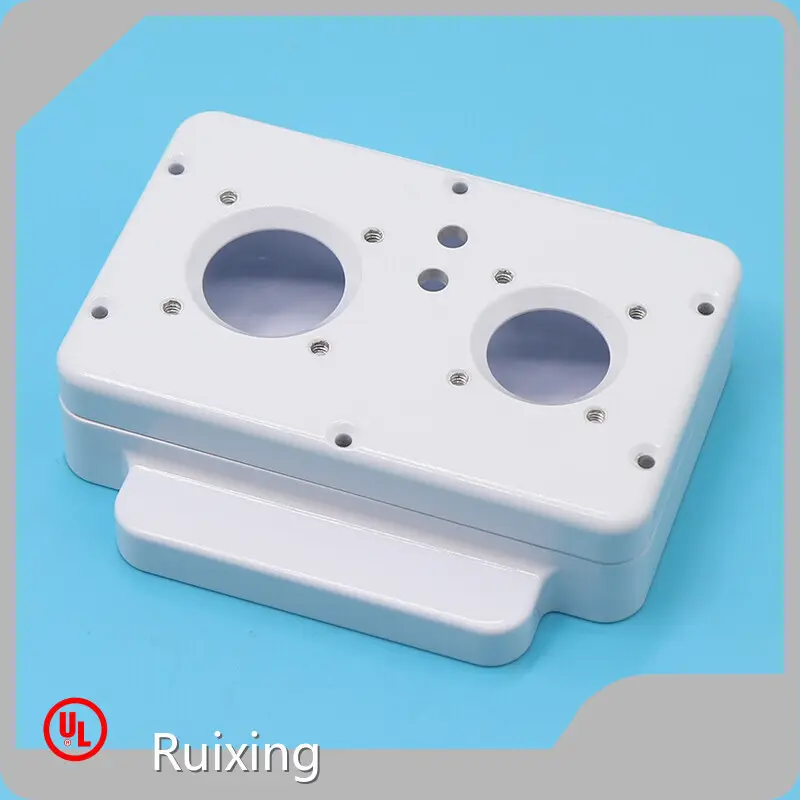

Precision Machined Components by Ruixing

Product details of the precision machined components

Product Information

precision machined components from Shenzhen Ruixing Precision MFG creates a novel product style through innovations in the terms of material and out-look design. The product surpasses the similar products in terms of service life. As long as there is request for help about design or other things, Shenzhen Ruixing Precision MFG will be ready to help for our customers.

Characteristic

1. Surface Finish:

The powder coating process enhances the aesthetics and durability of aluminum parts, providing a smooth, even finish with a thickness ranging from 0.002 to 0.006 inches.

2. Material Selection:

Aluminum's lightweight and corrosion-resistant properties make it an ideal choice for CNC machining, while the powder coating adds an extra layer of protection against environmental elements.

3. Temperature Resistance:

The cured powder coating offers heat resistance, ensuring that CNC machined aluminum parts can withstand elevated temperatures without compromising performance.

4. Durability and Longevity:

Powder coating significantly improves the lifespan of CNC machined aluminum parts by providing a robust protective layer that resists scratches, chemicals, and UV exposure.

Advantages:

a. Enhanced Aesthetics:

Powder coating allows for a wide range of color options, enhancing the visual appeal of CNC machined aluminum parts.

b. Environmental Benefits:

The powder coating process is eco-friendly, producing minimal waste and emissions compared to traditional painting methods.

c. Cost-Effectiveness:

CNC machining with powder coating offers a cost-effective solution for producing high-quality, durable components with a streamlined production process.

Drawbacks:

a. Thickness Variation:

Achieving consistent powder coating thickness can be challenging, leading to potential variations in appearance and performance.

b. Limited to Certain Materials:

While suitable for aluminum, the powder coating process may not be compatible with certain materials, limiting material choices for specific applications.

Application

1. Automotive Industry:

From engine components to intricate dashboard elements, our CNC machined aluminum parts play a pivotal role in enhancing automotive performance. Powder-coated finishes not only provide aesthetic appeal but also ensure resilience against harsh weather conditions and road debris.

2. Electronics Sector:

In electronic enclosures, precision matters. Our CNC machining aluminum parts with powder coating, offer a robust shield against electromagnetic interference and environmental factors. These components find application in devices ranging from control panels to communication equipment.

3. Aerospace Components:

Critical aerospace components demand the highest precision. They contribute to the structural integrity of aircraft. From brackets to structural elements, our components adhere to stringent aerospace standards.

4. Medical Equipment:

In the medical field, precision is paramount. They contribute to the manufacturing of medical devices. From diagnostic equipment to structural components, our parts adhere to strict medical industry regulations.

5. Renewable Energy Solutions:

Precision components are crucial in renewable energy systems. Our CNC machining aluminum parts with powder coating, contribute to the construction of components in solar panels, wind turbines, and energy storage systems.

Powder Coating in CNC Machining

Introduction:

Powder coating is a dry finishing process where finely ground particles of pigment and resin are electrostatically charged and sprayed onto a conductive metal surface, such as aluminum components produced through CNC machining.

Key Points:

1. Application Process:

- Powder coating begins with the application of electrostatically charged powder particles to the surface of the metal component.

- The charged particles adhere to the surface, creating a uniform coating.

2. Curing:

- After application, the coated component undergoes a curing process, typically in an oven.

- The heat causes the powder particles to melt, flow, and then cure into a durable, smooth finish.

3. Benefits:

- Powder coating enhances the durability of CNC machined components, providing resistance to corrosion, chemicals, and UV exposure.

- The process offers an extensive range of color options, contributing to the aesthetic appeal of the finished product.

4. Environmental Considerations:

- Powder coating is environmentally friendly, producing minimal volatile organic compounds (VOCs) compared to traditional liquid coatings.

- It reduces waste by allowing for the reuse of overspray, contributing to sustainable manufacturing practices.

FAQ

Company Advantage

• We pay attention to the impact of service effects on public praise. Based on this, we are committed to providing professional services and making progress together with consumers.

• According to the management system of modern enterprise, our company has established an elite team. They have rich industry experience in production, processing and sales.

• Since the establishment in we have continuously innovated our business model and established and improved the management system of modern enterprise. So we have finally found an industrialized development path.

All walks of life are welcomed to visit and negotiate.