Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

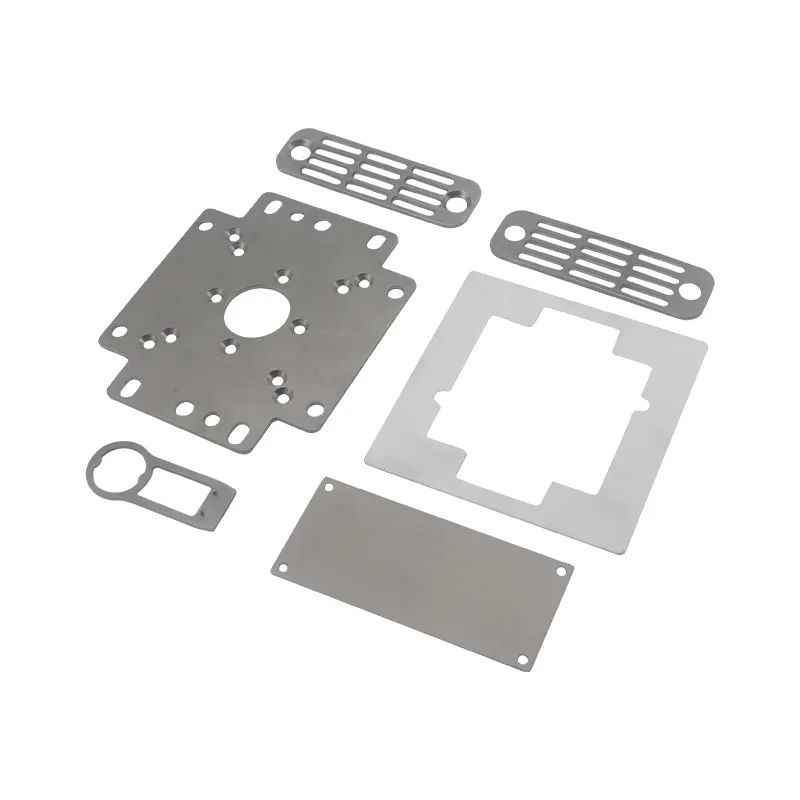

Laser Cutting Parts by Ruixing

Product details of the laser cutting parts

Product Description

laser cutting parts can be specially tailored according to customers' products and process requirements. Its first-class performance is loved by global customers. High efficient production of laser cutting parts contributes to the introduction of advanced machines.

Feature

◎ Precision:

One of the most significant benefits of laser cutting parts is their unmatched precision. Laser cutting produces a narrow and concentrated beam of light, which can be adjusted to create precise cuts with a high level of accuracy. This allows for clean, straight, and uniform cutting that meets the exact specifications and requirements of the customer.

◎ Quality:

Laser-cut parts have a superior surface quality that is free of burrs, dross, and other imperfections. This is because laser cutting does not involve any physical contact with the material, thus eliminating any chances of damage. The result is a clean and smooth cut that requires minimal finishing or post-processing.

◎ Speed:

Laser cutting is a fast and efficient process that can produce parts faster than traditional cutting methods, allowing for shorter lead times and faster turnaround times. This can significantly reduce production costs and increase overall productivity.

◎ Versatility:

Laser cutting can work with a variety of materials, including metals, plastics, ceramics, and composites. In addition, it can cut complex shapes and intricate designs, making it ideal for creating customized and unique parts.

◎ Cost-Effective:

Laser cutting can save costs by reducing scrap material and increasing the efficiency of the cutting process. It also eliminates the need for specialized tooling or dies, resulting in shorter setup times and lower labor costs.

Applications 01

◎ Aerospace and Defense:

Laser cutting parts are commonly used in the aerospace and defense industries, where precision and accuracy are crucial. The process is used to produce parts for aircraft engines, frames, and panels, as well as missile and satellite components.

◎ Automotive:

Laser cutting is widely used in the automotive industry to produce parts such as chassis components, exhaust systems, and engine parts. It is also used for welding, engraving, and marking applications.

◎ Electronics:

The electronics industry relies on laser cutting to produce components for phones, tablets, and computers. Laser cutting is also used to create metal stencils used in the production of printed circuit boards (PCBs).

Application 02

◎ Medical Equipment:

Laser cutting parts are crucial in the medical equipment industry, where precision and accuracy are vital. Laser-cut components are used in the production of surgical tools, implants, and diagnostic equipment.

◎ Architecture and Art:

Laser cutting is gaining popularity in the field of architecture and art for its ability to create intricate designs and unique shapes. Laser-cut parts are used in building facades, interior design, sculptures, and installations.

FAQ

Company Feature

• Our company wholeheartedly provides customers with sincere and reasonable services.

• Ruixing is located in the area of convenient traffic, with a great number of shopping facilities. This makes a convenient condition for transportation.

• We have a group of technical staff with many years of experience in professional project and middle and senior scientific and technical personnel with rich scientific research experience, which provides a very solid technical force for our product development and business activities.

Do you fully understand Ruixing? In the future, Ruixing will provide more consumer electronics and accessories. Please leave your contact information, and you will find a new world.