Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

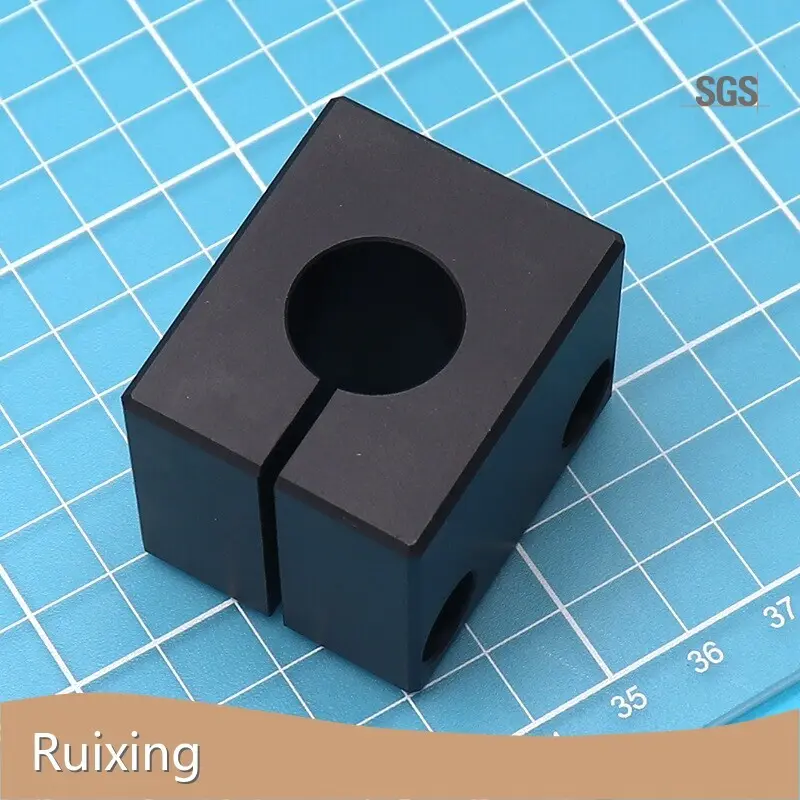

Custom Machined Plastic Parts CNC Milling by Ruixing

Product details of the custom machined plastic parts

Quick Detail

The whole production of Ruixing custom machined plastic parts is finely finished by our dedicated experienced production team. Its quality is guaranteed by a team of people following the relative certificates. Over the years, Shenzhen Ruixing Precision MFG has insisted on optimizing products structure.

Product Information

Ruixing's custom machined plastic parts has better performances, as shown below.

Characteristic

1. Dimensional Stability:

The addition of 40% glass fiber enhances PPS's dimensional stability, ensuring that machined parts maintain precise dimensions even under varying temperatures.

2. High Heat Resistance:

PPS GF40 parts boast an elevated heat resistance, with a continuous operating temperature reaching approximately 240°C (464°F). This makes them suitable for applications in demanding thermal environments.

3. Excellent Mechanical Strength:

The incorporation of glass fiber significantly reinforces the mechanical strength of PPS. Tensile strength can range around 120 MPa, providing robustness crucial for diverse industrial applications.

4. Low Water Absorption:

PPS GF40 exhibits low water absorption, a vital property for components exposed to humid or wet conditions. This characteristic ensures stability and reliability in varied environments.

5. Chemical Resistance:

PPS GF40 parts showcase excellent resistance to a wide range of chemicals, making them suitable for applications in aggressive industrial settings where exposure to chemicals is inevitable.

Advantages:

- Enhanced Dimensional Stability

- High Heat Resistance

- Exceptional Mechanical Strength

- Low Water Absorption

- Outstanding Chemical Resistance

Disadvantages:

- Higher Material Cost

- Increased Abrasion on Machining Tools

Application

1. Automotive Sector:

Custom CNC machined PPS GF40 parts play a vital role in the automotive industry, particularly within engine components. Their robust nature, heat resistance, and dimensional stability make them ideal for critical applications.

2. Aerospace Industry:

In aerospace, where precision and durability are non-negotiable, they find applications in structural components. Their lightweight yet sturdy nature contributes to enhanced performance.

3. Electronics Manufacturing:

They are integral to electronics manufacturing, serving in connectors and housings. The material's excellent mechanical properties ensure the longevity of electronic devices.

4. Industrial Equipment:

Within industrial equipment, these parts find a place in gear systems. The high strength and wear resistance of PPS GF40 contribute to the efficiency and reliability of gear mechanisms.

5. Medical Devices:

Precision is paramount in the medical field. PPS GF40 parts, known for their dimensional stability, are used in the manufacturing of surgical instrument components.

6. Oil and Gas Sector:

In the oil and gas industry, where harsh conditions prevail, custom CNC machined PPS GF40 parts are employed in valve components. Their resistance to chemicals and extreme temperatures ensures optimal performance.

FAQ

Company Introduction

a company, specializes in the production, processing, and sales of CNC Machining Services,Sheet Metal Fabrication. To ensure the timely explanation to consumers questions, we have established a complete service system of pre-sales, in-sales and after-sales. So customers' legal right would be protected. Our products are of reliable quality, with great cost performance and you can purchase them with confidence. If you are in need, please contact us for business discussion.