Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

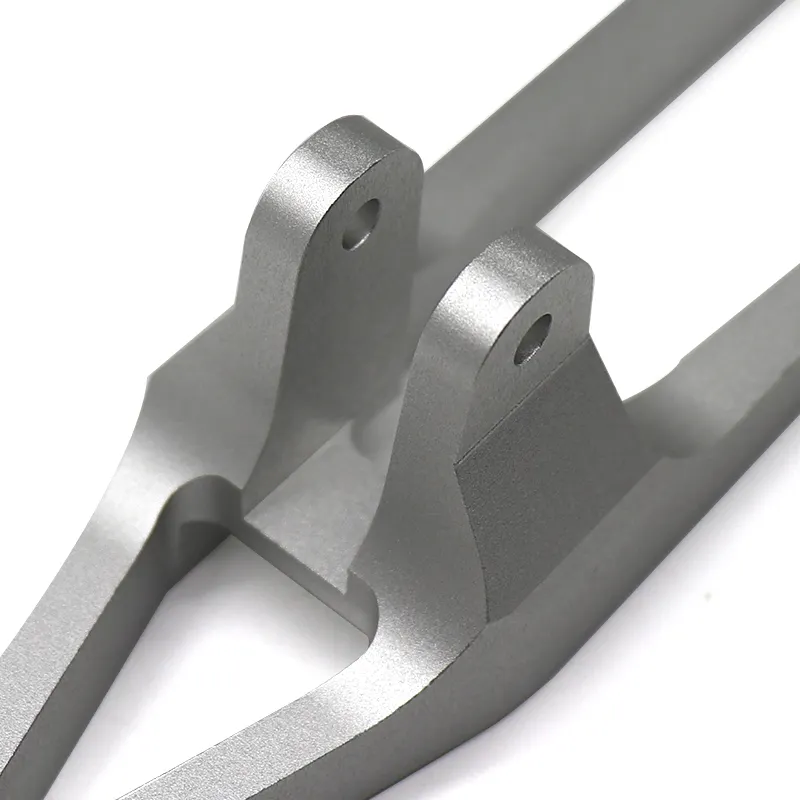

Cnc Aluminium Parts Anodizing - - Ruixing

Product details of the cnc aluminium parts

Product Information

In the design of Ruixing cnc aluminium parts, a professional market survey is carried out according to customers' demands. As a result of innovative ideas and technologies, it is user-friendly. Its quality and performance is widely recognized in various exhibitions. This product is at feasible market prices to meet the specific requirements of customers.

Feature

6061 Aluminum stands as a versatile material with distinct characteristics, making it a popular choice for CNC machined parts. Delve into the specifics to comprehend its attributes:

1. Composition:

- Primarily composed of aluminum (97.9%).

- Alloyed with magnesium (1.0%) and silicon (0.6%).

2. Tensile Strength:

- Tensile strength ranges from 40,000 to 45,000 psi.

- Exhibits a balance of strength and formability.

3. Density:

- Possesses a density of 2.70 g/cm³.

- Contributes to the lightweight nature of components.

4. Melting Point:

- Melting point recorded at approximately 582°C (1080°F).

- Allows for effective machining without compromising structural integrity.

5. Thermal Conductivity:

- Exhibits high thermal conductivity at 167 W/m-K.

- Facilitates efficient heat dissipation in CNC machining.

6. Yield Strength:

- Yield strength ranges between 34,000 and 40,000 psi.

- Provides stability and durability under various loads.

Advantages:

1. Versatility:

Suitable for a wide range of applications due to its balanced properties.

2. Corrosion Resistance:

Forms a protective oxide layer, enhancing resistance to corrosion.

3. Machinability:

Exhibits excellent machinability, facilitating intricate CNC machining.

4. Weldability:

Easily welded using various techniques, enhancing fabrication possibilities.

5. Aesthetics:

Anodizing and other finishes can be applied for improved aesthetics.

Disadvantages:

1. Strength Limitation:

Compared to some alloys, it may have limitations in high-stress applications.

2. Surface Finish:

Achieving a high-quality surface finish can be challenging in certain machining operations.

3. Cost:

Slightly more expensive than standard carbon steels.

Application

1. Aerospace Excellence:

In the aerospace industry, where reliability is paramount, our 6061 Aluminum CNC Machined Parts shine. From structural components to intricate aerospace parts, the high strength and corrosion resistance of these components ensure optimal performance in challenging flight conditions.

2. Automotive Precision:

Precision matters in the automotive sector, and our CNC machined parts meet the demand. From engine components to critical parts in vehicle assemblies, the reliability and machinability of 6061 aluminum contribute to the efficiency and longevity of automotive systems.

3. Electronics and Technology:

In the fast-paced world of electronics, precision is key. Our CNC machined parts play a vital role in electronic devices, ensuring the accuracy and reliability required for intricate electronic components and assemblies.

4. Industrial Machinery:

The industrial sector benefits from the durability and machinability of our CNC machined parts. From heavy machinery components to intricate parts in manufacturing equipment, the versatility of 6061 aluminum contributes to the robustness of industrial machinery.

5. Marine Engineering:

In marine applications, where corrosion resistance is crucial, our CNC machined parts excel. From ship components to offshore structures, the corrosion-resistant properties of 6061 aluminum ensure longevity in challenging marine environments.

6. Medical Device Precision:

The medical industry demands precision and biocompatibility. Our CNC machined parts find applications in medical devices, providing the necessary accuracy and reliability for critical components like surgical instruments and implants.

7. Renewable Energy Components:

In the renewable energy sector, where efficiency is paramount, our 6061 aluminum CNC machined parts contribute to the production of reliable components for solar panels, wind turbines, and other renewable energy systems.

FAQ

Company Feature

• Since the beginning in Ruixing has been adhering to the brand development strategy and focusing on product quality and technological innovation. Now we have an industry-leading research and development strength and technical level.

• Ruixing has a group of professional and experienced technical personnel to ensure the development and production of high-quality products.

• Through continuous improvement of sales channels, our company has established an unobstructed market channel and sales network at home and abroad with our major distribution outlets. It expands the visibility of our products.

• Abiding by the service concept of 'customers first, satisfaction-oriented', we provide you with professional consulting and after sales service.

Dear customer, if you are interested in Ruixing's CNC Machining Services,Sheet Metal Fabrication and would like to know more details, please feel free to contact us. We will provide professional services!