Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

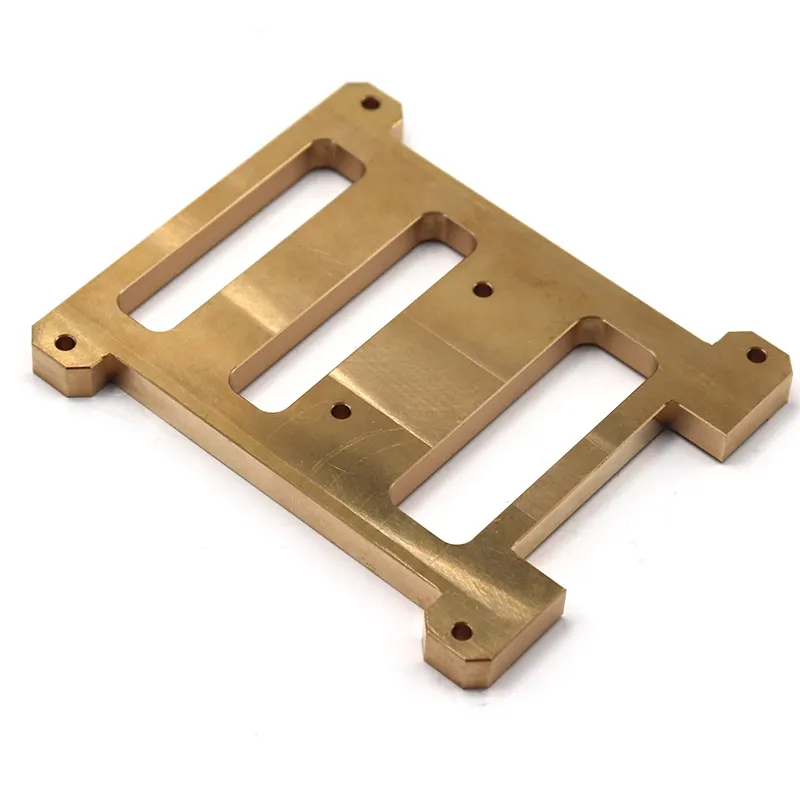

Brass Cnc Parts None - - Ruixing

Product details of the brass cnc parts

Quick Overview

The materials of Ruixing brass cnc parts are sourced from suppliers that enforce strict social standards in their factories. Every aspect of the product has been rigorously tested to meet international quality standards. brass cnc parts has a wide range of applications. QC is strictly incorporated into every procedure of brass cnc parts's production.

Product Introduction

Compared with similar products, the brass cnc parts of Ruixing is more strict in the selection of raw materials. The specific aspects are as follows.

Characteristic

1. Composition:

- H59 brass is a copper-zinc alloy with a nominal composition of approximately 59% copper and 40% zinc.

2. Mechanical Properties:

- Tensile Strength: 410 MPa

- Yield Strength: 310 MPa

- Elongation: 15%

- Hardness (HV): 110-140

3. Thermal Properties:

- Melting Point: 902°C

- Thermal Conductivity: 120 W/(m·K)

4. Electrical Conductivity:

- Electrical Conductivity:

27% IACS (International Annealed Copper Standard)

Pros:

- Machinability:

H59 brass exhibits excellent machinability, making it well-suited for precision CNC milling processes.

- Corrosion Resistance:

The material's corrosion resistance is advantageous in various applications, ensuring durability in diverse environments.

- Electrical Conductivity:

H59 brass's moderate electrical conductivity is beneficial in applications requiring electrical components.

Cons:

- Cost:

Compared to some other alloys, H59 brass can be relatively more expensive.

- Not Suitable for Extreme Temperatures:

Its moderate melting point limits its use in applications requiring resistance to high temperatures.

Challenges in CNC Machining:

- Tool Wear:

The machining process may lead to increased tool wear due to the material's abrasiveness.

- Chip Control:

Effective chip control is essential during CNC milling to prevent issues related to chip formation and evacuation.

In precision CNC milling of H59 brass parts, understanding these characteristics, pros, cons, and associated challenges is imperative. Our CNC machining expertise ensures meticulous handling of H59 brass, delivering customized solutions that align with the unique demands of OEM applications.

Application

1. Automotive Sector:

RuiXing precision CNC milling H59 brass parts find applications in the automotive sector, contributing to the manufacturing of critical parts such as gears, bushings, and connectors. The durability and precision of these parts ensure optimal performance and longevity in demanding automotive environments.

2. Electronics Manufacturing:

In the electronics industry, they are integral to the production of connectors, sockets, and other intricate components. The material's excellent electrical conductivity and machining precision make it a preferred choice for electronic devices and systems.

3. Aerospace Components:

The aerospace industry benefits from the CNC milling of H59 brass for components like fasteners and structural elements. The combination of high strength and precision is crucial in meeting the stringent standards and reliability requirements of aerospace applications.

4. Medical Equipment:

They play a role in medical equipment manufacturing, contributing to the production of components for devices such as diagnostic instruments, imaging equipment, and surgical tools. The material's biocompatibility and precision are vital in medical applications.

5. Industrial Machinery:

H59 brass components, crafted through precision CNC milling, find applications in industrial machinery, contributing to the production of gears, bearings, and other critical parts. The material's strength and wear resistance are essential for ensuring the longevity of machinery.

6. Energy Sector:

Within the energy sector, RuiXing precision CNC milling H59 brass parts are utilized in the production of components for renewable energy systems, electrical equipment, and power generation machinery. The material's reliability and resistance to corrosion make it suitable for various energy applications.

FAQ

Company Introduction

Shenzhen Ruixing Precision MFG is a modern company that produces CNC Machining Services,Sheet Metal Fabrication in shen zhen. Ruixing constantly improves product quality and service system depending on technical advantages. Now we have a nationwide marketing service network. Welcome all customers to come for cooperation.