Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

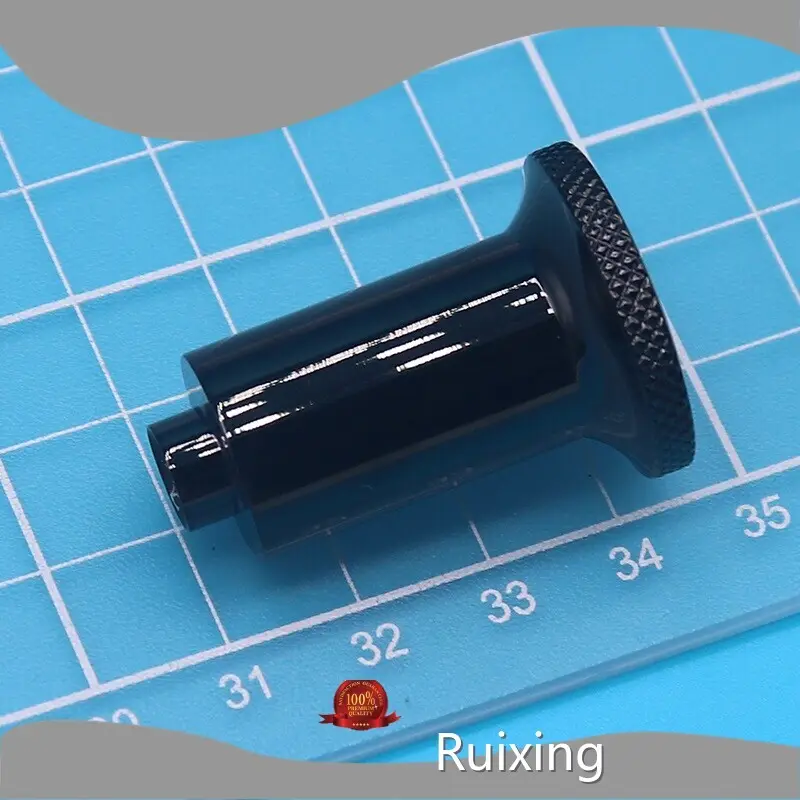

Aluminum Parts Machining PVD Coating - - Ruixing

Product details of the aluminum parts machining

Product Description

Ruixing aluminum parts machining is precisely accurate to the design specifications. aluminum parts machining is located in the high-end market. With strong sense of responsibility, Ruixing staff are devoted themselves into producing exquisite aluminum parts machining.

Characteristic

1. Material Composition:

- 6061 Aluminum Alloy:

Composed primarily of aluminum, with additions of magnesium and silicon for improved strength and corrosion resistance.

- PVD Coating:

Thin film coating applied through physical vapor deposition (PVD) process, enhancing surface hardness and wear resistance.

- Polishing:

Surface polishing process for achieving smooth finishes and aesthetic appeal.

2. Mechanical Properties:

- Tensile Strength:

Typically ranges from 30,000 to 45,000 psi (207 to 310 MPa), providing good strength-to-weight ratio for various applications.

- Yield Strength:

Approximately 40,000 psi (276 MPa), indicating the stress at which the material begins to deform permanently.

- Hardness:

Around 95 HRB (Rockwell B Hardness) after PVD coating, ensuring resistance to abrasion and scratching.

3. Surface Finish:

- Mirror-Like Finish:

Achieved through polishing process, enhancing aesthetics and corrosion resistance.

- Low Coefficient of Friction:

PVD coating reduces friction coefficient, improving wear resistance and lubricity.

- Uniform Coating Thickness:

PVD coating ensures uniform coverage, preventing uneven wear and corrosion spots.

4. Dimensional Accuracy:

- Tight Tolerances:

CNC turning process enables precise machining with tolerances as tight as ±0.001 inches (0.025 mm), ensuring dimensional accuracy and consistency.

- Repeatable Results:

Advanced CNC technology ensures repeatability in part production, minimizing variation between batches.

5. Corrosion Resistance:

- Anodizing Compatibility:

6061 aluminum is suitable for anodizing processes, further enhancing corrosion resistance and surface durability.

- PVD Coating Protection:

Provides an additional layer of protection against corrosion, extending the lifespan of the parts in harsh environments.

Application

1. Sporting Goods:

- Bicycle Components:

From lightweight handlebars to sturdy pedal brackets, custom CNC turning 6061 aluminum parts with PVD coating and Polishing offer durability and corrosion resistance for high-performance bicycles.

- Archery Equipment:

Components like arrow rests and sight brackets benefit from the precision machining and surface finishing of CNC-turned aluminum parts with PVD coating, ensuring accuracy and reliability in archery gear.

2. Marine Industry:

- Boat Accessories:

They are utilized in marine applications, including boat cleats, rod holders, and anchor brackets, providing resistance to saltwater corrosion and harsh environmental conditions.

- Wakeboard Tower Components:

Tower mounts and wakeboard racks made from CNC-turned aluminum parts with PVD coating offer strength and longevity, enhancing the performance and aesthetics of wakeboarding accessories.

3. Recreational Vehicles (RVs):

- RV Interior Fixtures:

From cabinet handles to curtain rods, they add durability and a modern touch to RV interiors, withstanding the rigors of travel and use.

- Exterior Trim Components:

Door handles, window frames, and awning brackets made from CNC-turned aluminum parts with PVD coating offer weather resistance and aesthetic appeal, enhancing the overall look and functionality of RV exteriors.

4. Industrial Equipment:

- Conveyor Systems:

Roller brackets and guide rails made from them provide smooth and reliable operation in conveyor systems, contributing to efficient material handling in industrial settings.

- Packaging Machinery:

Components such as gripper fingers and sealing jaws benefit from the precision and durability of CNC-turned aluminum parts with PVD coating, ensuring consistent performance in packaging equipment.

5. Robotics:

- Robotic Arm Components:

Joints, end effectors, and grippers made from them offer lightweight yet robust solutions for robotic systems, enhancing agility and performance in automation tasks.

- Drone Frames:

UAV frames and motor mounts benefit from the precision machining and corrosion resistance of CNC-turned aluminum parts with PVD coating, ensuring structural integrity and longevity in drone applications.

6. Musical Instruments:

- Percussion Instrument Hardware:

Drum lugs, pedal brackets, and cymbal mounts made from them provide durability and aesthetic appeal for high-quality percussion instruments, enhancing sound and playability.

- Guitar Hardware:

From tuning machine heads to bridge saddles, CNC-turned aluminum parts with PVD coating offer precise tuning stability and corrosion resistance for guitar components, contributing to the performance and longevity of musical instruments.

7. Medical Devices:

- Rehabilitation Equipment:

They are used in rehabilitation devices such as prosthetic limbs and orthopedic braces, offering lightweight and durable solutions for patient mobility and support.

- Surgical Robotics:

Components for robotic surgical systems, including instrument holders and camera mounts, benefit from the precision machining and biocompatibility of CNC-turned aluminum parts with PVD coating, ensuring safe and effective surgical procedures.

8. Aerospace Prototyping:

- Unmanned Aerial Vehicles (UAVs):

Custom CNC turning 6061 aluminum parts with PVD coating and Polishing are utilized in UAV prototypes for components such as airframes and landing gear, providing lightweight and aerodynamic solutions for aerial exploration and research.

- Spacecraft Subsystems:

From satellite components to space probe instrumentation, CNC-turned aluminum parts with PVD coating offer reliability and performance in harsh space environments, contributing to the success of space exploration missions.

FAQ

Company Advantage

• Our company is located in a superior geographical position. And we are enjoying abundant resources and convenient transportation. It is a good natural and human geographical environment.

• It is a long way to go for our enterprise to develop. Our own brand image is related to whether we are capable of providing customers with quality services. Thus, we proactively integrate peer advanced service concept and the advantages of our services. To satisfy different needs of consumers, we are sticking to provide consumers with diverse services including pre-sales, sales, after-sales service.

• We have a broad market for our products. They are currently sold well in various regions at home and abroad.

• Since the establishment in our company has gone through ups and downs for years. Our product range continues to increase and our business scope continues to expand. This experience has allowed us to accumulate a wealth of experience in production and processing, and promoted us to increase our market visibility and brand influence.

Ruixing's CNC Machining Services,Sheet Metal Fabrication are available in diverse types, favorable price and they are comfortable and durable. If you have needs to order in bulk, please leave your contact information. We will open channels for you.