Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

Aluminum Cnc Turning Parts 6061 Aluminum CNC Machining Parts Wholesale - Ruixing

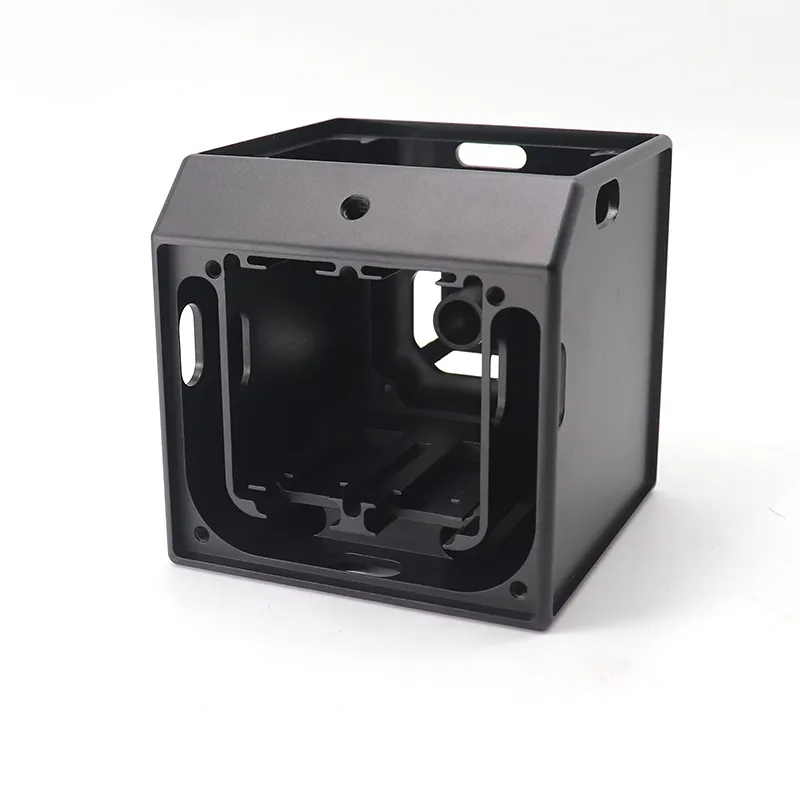

Product details of the aluminum cnc turning parts

Product Information

Ruixing aluminum cnc turning parts is an innovation-oriented product with improvement on production process. The product has the advantages of good quality and excellent performance. Shenzhen Ruixing Precision MFG has set up the top platform of commercial resource in the world.

Characteristic

1. Precision Tolerances:

Achieving exceptional precision, our custom CNC precision 6061 aluminum machining service maintains tight tolerances as low as +/- 0.02mm, ensuring exact conformity to design specifications.

2. Surface Finish Control:

We offer controlled surface finishes on 6061 aluminum parts, ranging from matte to glossy, providing aesthetic versatility for varied applications.

3. Material Composition:

Crafted from the resilient 6061 aluminum alloy, our service ensures a balanced combination of strength, corrosion resistance, and machinability.

4. Anodized Coating Thickness:

The anodized coating thickness on custom aluminum parts can be precisely controlled, typically ranging from 5 to 25 microns, ensuring durability and corrosion resistance.

5. Complex Geometries and Intricate Designs:

Leveraging CNC milling capabilities, intricate designs and complex geometries are achieved, allowing for versatility in component shapes and configurations.

Advantages:

a. Enhanced Aesthetics:

The anodized finish on custom aluminum parts enhances visual appeal, offering various colors and textures for customizable aesthetics.

b. Corrosion Resistance:

Anodized coating provides superior corrosion resistance, ensuring longevity by protecting aluminum parts from environmental elements.

c. Improved Surface Hardness:

Anodizing enhances surface hardness, increasing resistance to scratches, abrasion, and wear, ensuring durability in demanding applications.

d. Thermal Insulation:

Anodized 6061 aluminum parts exhibit improved thermal insulation properties, making them suitable for applications requiring heat dissipation or thermal barrier properties.

Product Advantages

1. Aerospace Industry - Structural Components:

Precision machining of 6061 aluminum is crucial for producing lightweight yet sturdy structural components in aerospace, such as aircraft frames, panels, and brackets.

2. Automotive Sector - Engine Parts:

Within the automotive realm, our custom CNC precision 6061 aluminum machining service is utilized for crafting precise engine components from 6061 aluminum, ensuring optimal performance and durability.

3. Electronics Manufacturing - Heat Sinks:

In electronics, the machining of 6061 aluminum is employed to create efficient heat sinks, playing a vital role in heat dissipation for electronic devices.

4. Medical Equipment - Instrument Housings:

The medical industry benefits from CNC precision machining for manufacturing instrument housings and components from 6061 aluminum, maintaining a delicate balance between strength and weight.

5. Industrial Equipment - Gearbox Housings:

For industrial applications, our machining service is instrumental in producing gearbox housings and components, where the durability of 6061 aluminum is paramount.

6. Renewable Energy - Wind Turbine Parts:

In the renewable energy sector, CNC machining is applied to create precise components for wind turbines, leveraging the lightweight and corrosion-resistant properties of 6061 aluminum.

7. Telecommunications - Antenna Components:

Telecommunication equipment relies on precision machining for crafting antenna components from 6061 aluminum, ensuring signal strength and longevity.

8. Sporting Goods - Bicycle Frames:

Within the sporting goods industry, our machining service contributes to the production of bicycle frames, benefitting from the ideal combination of strength and weight offered by 6061 aluminum.

FAQ

Company Advantage

• Our company enjoys the advantaged location. The transportation here is much convenient because the roads, railways, and airports are all available.

• Ruixing provides competitive solutions and services based on customer demand,

• Ruixing has a talents team consisting of senior industry experts, elites and R&D personnel. They provide strong technical support for our company.

• Since the beginning in Ruixing has been continuously improving the production process and product quality. Now we gain industry recognition with high-quality products.

The products produced are qualified products of high quality. If you are interested in our products, please contact us!