Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

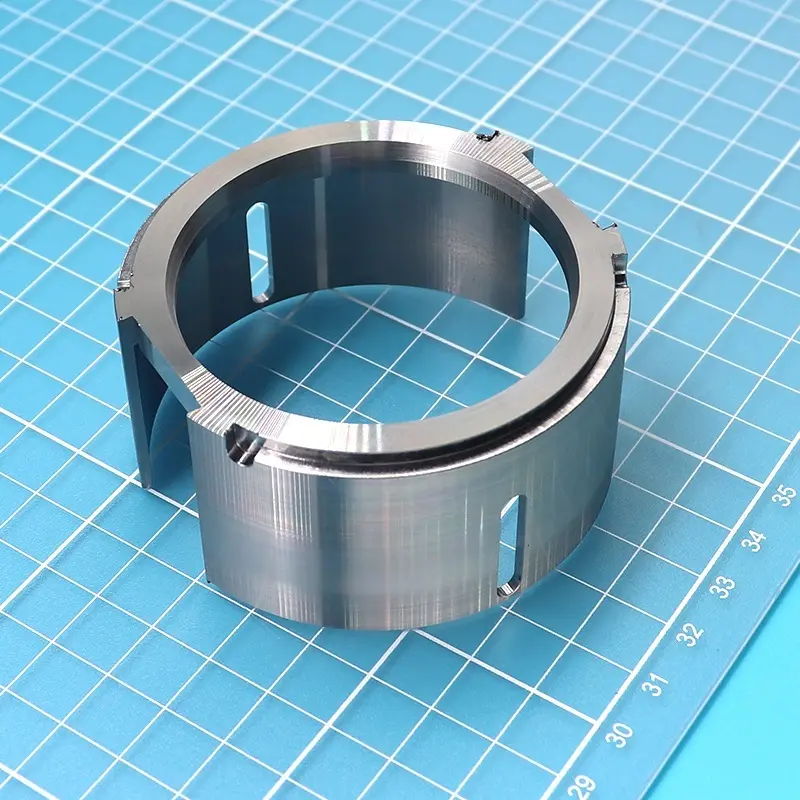

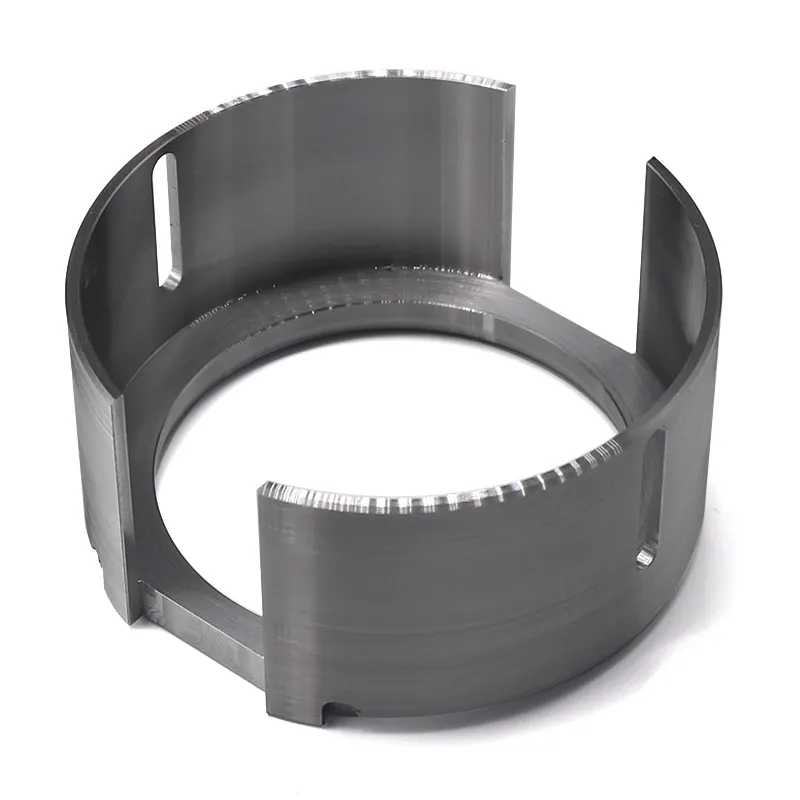

Metal Cnc Machined Parts 1018 Steel by Ruixing

Product details of the metal cnc machined parts

Product Overview

The metal cnc machined parts unique in its design are very famous. With the careful inspect from our dedicated and skilled crew of quality controllers at every step of production, the performance of this product remains exceptional with zero manufacturing defects. The metal cnc machined parts produced by our company is widely used in various industries and fields. More customers have recommended Ruixing to be their choices to purchase metal cnc machined parts.

Product Introduction

In the production, Ruixing believes that detail determines result and quality creates brand. This is the reason that we strive for excellence in every product detail.

Characteristic

1. Chemical Composition:

- Carbon Content: Approximately 0.18%

- Manganese Content: 0.6% - 0.9%

- Other Elements: Small amounts of sulfur and phosphorus

2. Mechanical Properties:

- Tensile Strength: 63,800 psi

- Yield Strength: 53,700 psi

- Hardness (Brinell): 126

3. Machinability:

- AISI 1018 steel boasts excellent machinability, making it ideal for precision CNC machining operations.

- Its low carbon content contributes to reduced tool wear and smoother surface finishes.

4. Weldability:

- Good weldability, both through conventional welding methods and resistance welding techniques.

- Suitable for welding with various filler materials.

5. Surface Finish:

- AISI 1018 steel offers a good surface finish when subjected to precision CNC machining processes.

- Proper machining techniques ensure the attainment of desired surface smoothness.

6. Advantages:

- Cost-Effective:

AISI 1018 steel is relatively inexpensive compared to other alloys, making it an economical choice for CNC machining projects.

- Machinability:

Its excellent machinability allows for efficient and precise CNC machining, reducing production time and costs.

- Weldability:

Good weldability facilitates ease of assembly and fabrication in various applications.

7. Disadvantages:

- Limited Strength:

While suitable for many applications, AISI 1018 steel may not offer the required strength for highly demanding or high-stress applications.

- Surface Hardness:

Compared to some other alloys, AISI 1018 steel may exhibit lower surface hardness, impacting its wear resistance in certain environments.

Application

1. Automotive Industry:

- Application:

AISI 1018 precision-machined components find use in automotive transmission systems.

- Benefit:

High machinability ensures intricate part designs for improved transmission performance.

2. Aerospace Sector:

- Application:

Critical aircraft components, such as brackets and connectors, benefit from precision CNC machining AISI 1018 steel service.

- Benefit:

The material's weldability and machinability contribute to lightweight yet robust aerospace parts.

3. Electronics Manufacturing:

- Application:

AISI 1018 parts are employed in electronic enclosures and connectors.

- Benefit:

Precision machining allows for intricate designs, crucial for electronic component assembly.

4. Medical Device Production:

- Application:

Surgical instruments and medical equipment housings benefit from precision machining in AISI 1018.

- Benefit:

High-quality surface finish and dimensional accuracy meet stringent medical industry standards.

5. Energy Sector:

- Application:

AISI 1018 components play a role in the production of oil and gas equipment.

- Benefit:

Robust machinability ensures durability in challenging environments.

6. Industrial Equipment Manufacturing:

- Application:

AISI 1018 precision-machined parts are utilized in the production of industrial machinery.

- Benefit:

Customizable machining addresses specific design requirements for diverse industrial applications.

7. Consumer Goods Production:

- Application:

Custom-designed AISI 1018 components find use in consumer appliances.

- Benefit:

The material's versatility and precision machining contribute to the reliability of consumer products.

FAQ

Company Information

Shenzhen Ruixing Precision MFG is a comprehensive enterprise mainly engaged in the production of CNC Machining Services,Sheet Metal Fabrication. The business also includes processing and sales. Our company adheres to the tenet of 'customer first and honesty-oriented' and the management philosophy of 'quality and excellence'. We make effort to get a lasting development while providing high-quality products, and look forward to work together and create brilliance with new and old customers in industry. Ruixing has a group of excellent sales staff and experienced production personnel, which provides favorable conditions for development and growth. With a focus on customers, Ruixing analyzes problems from the perspective of customers and provides comprehensive, professional and excellent solutions.

Welcome all customers to come for cooperation.