Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

Custom Copper Parts Ruixing MFG Wholesale - Ruixing

Company Advantages

· The design of Ruixing custom copper parts is carried out by a professional team.

· Each finished is strictly tested on a number of parameters.

· The product can help clients improve their competitiveness in the market, bringing wider market application.

Description

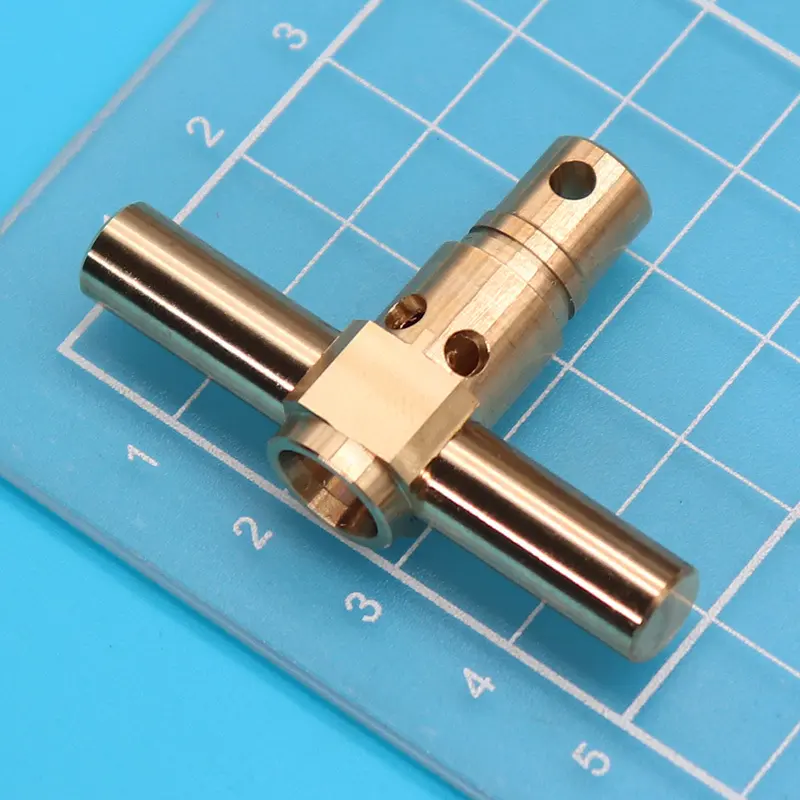

The 5-axis CNC machining process enables multi-angle cutting in a single setup, reducing production time while ensuring tight tolerances. This method is particularly advantageous for intricate designs, eliminating the need for multiple repositions and improving overall accuracy. Additionally, brass parts benefit from a smooth surface finish, which minimizes the need for secondary polishing.

Strict quality control measures, including dimensional inspections and material verification, ensure each component meets industry standards. With customizable specifications, manufacturers can produce brass parts tailored to specific functional and structural requirements.

For applications demanding high-performance materials with superior machinability, 5-axis CNC machining customized brass parts provide a reliable solution.

Applications

Electronics and Telecommunications

- RF Connectors and Terminals – Precision-machined brass connectors support signal transmission in communication systems.

- Circuit Board Components – Certain brass components are used in PCB assemblies for electrical conductivity and mechanical stability.

- Battery Contacts – Brass battery terminals provide efficient electrical connections in various consumer electronics.

Automotive and Transportation

- Cooling System Fittings – Brass components in radiators and coolant systems contribute to effective heat dissipation.

- Throttle and Fuel Injection Components – Machined brass parts are used in fuel delivery systems for controlled flow regulation.

- Ignition System Terminals – Brass terminals in ignition systems ensure stable electrical connections.

Aerospace and Satellite Technology

- Navigation System Housings – Brass enclosures protect delicate electronic components in navigation and control systems.

- Antenna Components – Machined brass parts are used in satellite communication antennas due to their electrical properties.

- Fluid Management Valves – Aircraft hydraulic and pneumatic systems rely on brass valves for consistent operation.

Medical and Laboratory Equipment

- Fluid Dispensing Nozzles – Precision brass nozzles are used in medical and laboratory devices for accurate fluid control.

- Gas Flow Regulators – Brass fittings are found in oxygen and anesthesia delivery systems.

- Analytical Instrument Components – Certain diagnostic instruments utilize machined brass parts for stable performance.

Industrial and Energy Sectors

- Power Distribution Components – Brass bus bars and connectors are used in power grids for conductivity and corrosion resistance.

- Mechanical Couplings – Brass couplings in automation systems provide durability and precision.

- Compressed Air System Fittings – Pneumatic systems in industrial environments incorporate brass components for reliable sealing.

FAQ

Company Features

· Shenzhen Ruixing Precision MFG is a professional supplier and manufacturer known with custom copper parts.

· The company has a team of patient and adaptable customer service professionals. They have abundant experience in handling irate, doubtful and chatty customers. Besides, they are always willing to learn how to provide better customer service.

· The tight network of sales and service training stations of Shenzhen Ruixing Precision MFG makes it easier to provide customers with more convenient services. Inquire!

Product Details

Compared with ordinary products, our custom copper parts has the specific differences as follows.

Application of the Product

Our custom copper parts has a wide range of applications.

With a focus on CNC Machining Services,Sheet Metal Fabrication, Ruixing is dedicated to providing reasonable solutions for customers.

Product Comparison

The custom copper parts mainly promoted by Ruixing have been further improved in the past through the technical improvement, which is reflected in the following aspects.