Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

Custom Cnc Metal Parts None Wholesale - Ruixing

Characteristic

1. Chemical Composition:

- Carbon (C): 0.38-0.43%

- Silicon (Si): 0.15-0.35%

- Manganese (Mn): 0.70-0.90%

- Phosphorus (P): ≤ 0.035%

- Sulfur (S): ≤ 0.040%

- Chromium (Cr): 0.70-0.90%

2. Mechanical Properties:

- Tensile Strength: 925-1020 MPa

- Yield Strength: 785 MPa (min)

- Elongation at Break: 13-17%

- Hardness (Brinell): 179-235 HB

3. Thermal Properties:

- Melting Point: 1460°C (2660°F)

- Specific Heat Capacity: 0.46 J/g-°C

4. Advantages:

- High Strength:

AISI 5140 steel exhibits excellent tensile strength and hardness, making it suitable for applications requiring robust mechanical properties.

- Wear Resistance:

With its chromium content, AISI 5140 steel offers good wear resistance, enhancing durability in demanding environments.

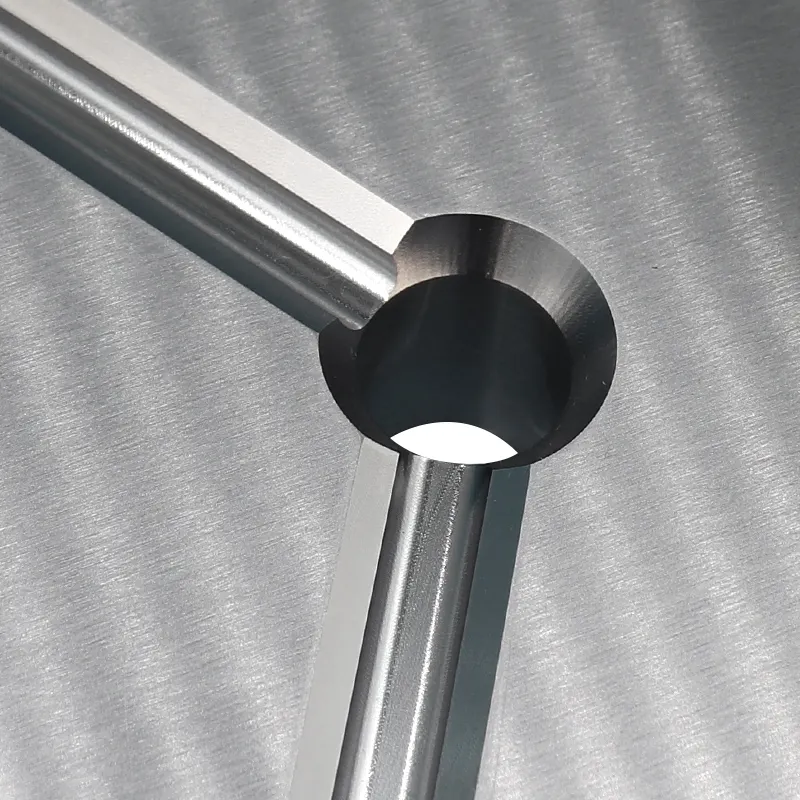

- Machinability:

The composition and microstructure of AISI 5140 steel facilitate ease of machining, allowing for efficient CNC precision milling operations.

5. Disadvantages:

- Limited Corrosion Resistance:

While AISI 5140 steel offers adequate corrosion resistance in certain environments, it may not be suitable for highly corrosive conditions without proper protection.

- Weldability Challenges:

Welding AISI 5140 steel requires preheating and post-weld heat treatment to prevent cracking and maintain mechanical properties, posing challenges in welding applications.

Application

1. Automotive Industry:

- Transmission Components:

AISI 5140 steel is used for manufacturing transmission gears, shafts, and other critical components due to its excellent strength, wear resistance, and machinability.

- Suspension System Parts:

CNC precision milling of AISI 5140 steel produces durable and reliable suspension system parts like control arms and linkages, ensuring superior performance and longevity.

2. Aerospace Sector:

- Landing Gear Components:

CNC-machined AISI 5140 steel parts are integral to landing gear assemblies, providing high strength and fatigue resistance to withstand the demanding conditions of flight operations.

- Engine Mounts:

Precision-milled AISI 5140 steel components play a crucial role in engine mount systems, offering robust support and vibration damping properties for aircraft engines.

3. Machinery Manufacturing:

- Industrial Gears:

AISI 5140 steel is widely utilized in CNC milling for producing industrial gears, offering excellent load-bearing capacity, toughness, and resistance to wear and deformation.

- Hydraulic Components:

CNC-machined AISI 5140 steel parts are essential in hydraulic systems, ensuring reliable performance under high pressure and dynamic operating conditions.

4. Renewable Energy:

- Wind Turbine Components:

CNC precision milling with AISI 5140 steel fabricates various wind turbine parts such as shafts, hubs, and gearboxes, delivering the durability and strength required for renewable energy generation.

FAQ

Company Advantages

· In the design of Ruixing custom cnc metal parts, we pay close attention to its aesthetics.

· Our quality testing department ensures that the product is of the quality that meets with the industry standards.

· Shenzhen Ruixing Precision MFG has experienced management and technical team.

Company Features

· Shenzhen Ruixing Precision MFG is a global manufacturer for custom cnc metal parts.

· Our custom cnc metal parts are available in various colors and shapes for more convenience.

· The company’s focus is to make our customers the highest priority with the goal of product quality and superior results. Any requirements or improvements in the products are treated seriously by our production team.

Application of the Product

Ruixing's custom cnc metal parts has a wide range of applications.

We are willing to understand the real needs of our customers. Then, we will provide the best solutions to their needs.