Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

Cnc Metal Parts Manufacturer ASTM A572 Grade 50 / EN 10025 S355JR by Ruixing

Characteristics

1. Chemical Composition:

- Carbon (C): 0.23%

- Manganese (Mn): 1.35%

- Phosphorus (P): 0.04%

- Sulfur (S): 0.05%

- Silicon (Si): 0.40%

- Vanadium (V): 0.015% - 0.05%

2. Mechanical Properties:

- Tensile Strength (Ultimate): 450 MPa (65,300 psi)

- Yield Strength (0.2% Offset): 345 MPa (50,000 psi)

- Elongation at Break (in 200 mm): 18%

- Modulus of Elasticity: 200 GPa (29,000 ksi)

3. Physical Properties:

- Density: 7.85 g/cm³ (0.284 lb/in³)

- Electrical Conductivity: 23% IACS

- Thermal Conductivity: 60.3 W/m·K (419 BTU·in/(hr·ft²·°F))

Advantages of ASTM A572 Grade 50 Steel:

1. High Strength:

- ASTM A572 Grade 50 steel exhibits excellent strength-to-weight ratio, making it suitable for applications requiring structural integrity and load-bearing capacity.

2. Good Weldability:

- With proper welding procedures, ASTM A572 Grade 50 steel can be easily welded, offering versatility and flexibility in fabrication processes.

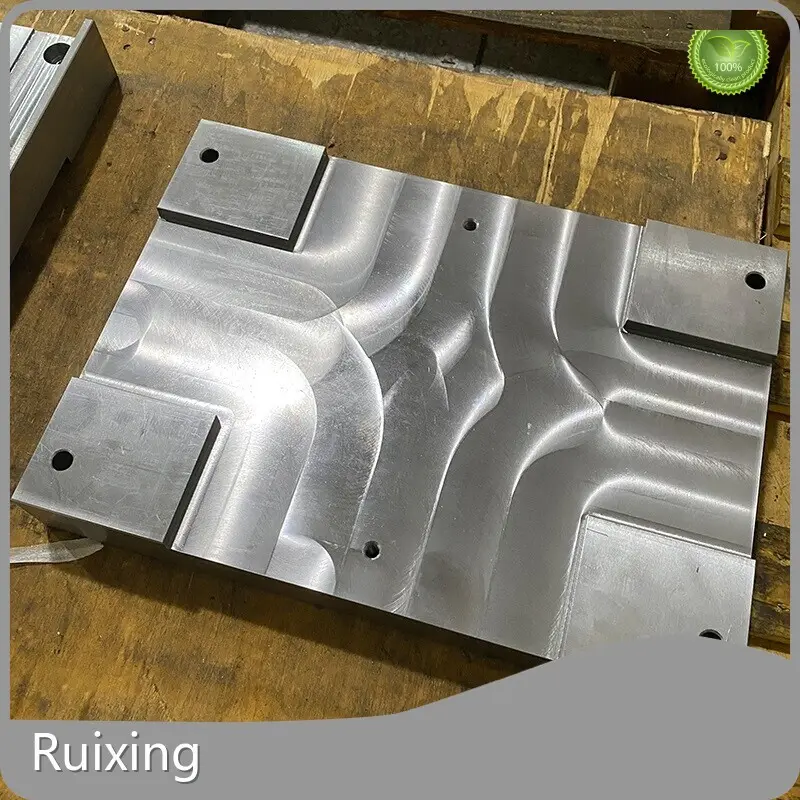

3. Enhanced Formability:

- This steel grade possesses good formability characteristics, allowing for the creation of complex shapes and intricate designs through CNC milling processes.

Disadvantages of ASTM A572 Grade 50 Steel:

1. Cost:

- Compared to standard carbon steels, ASTM A572 Grade 50 steel may have a higher initial cost due to its alloying elements and enhanced properties.

2. Machinability Challenges:

- While ASTM A572 Grade 50 steel is machinable, its high strength and hardness may pose challenges during machining operations, requiring specialized tooling and techniques.

Application

Aerospace Sector:

Within the aerospace industry, custom precision CNC Milling ASTM A572 Grade 50 steel parts are utilized in aircraft structural components, including fuselage frames, wing ribs, and landing gear assemblies. These high-strength, lightweight components meet stringent aerospace standards for safety and reliability.

Construction Sector:

In construction, they are integral to structural frameworks, beams, and columns in commercial and industrial buildings, bridges, and infrastructure projects. CNC milling ensures precise fabrication of these components, enhancing structural stability and longevity.

Heavy Machinery Manufacturing:

Heavy machinery manufacturers rely on them for equipment such as excavators, bulldozers, and cranes. These robust components withstand heavy loads and harsh operating conditions, contributing to the efficiency and reliability of industrial machinery.

Oil and Gas Industry:

Within the oil and gas sector, they parts are used in drilling equipment, pipelines, and offshore platforms. CNC milling ensures the fabrication of durable components that withstand corrosive environments and extreme temperatures in oil and gas operations.

Marine Applications:

In marine engineering, custom precision CNC Milling ASTM A572 Grade 50 steel parts are employed in shipbuilding, offshore structures, and marine propulsion systems. CNC machining delivers components with precise dimensions and superior mechanical properties, ensuring performance and longevity in maritime environments.

FAQ

Company Advantages

· Ruixing cnc metal parts manufacturer is manufactured under the guidance of our experienced professionals, using advanced machines and tools in tandem with international quality standards.

· The product has a complete life cycle due to the strict testing which is in line with the internal and external standards. Thus, the product is durable in use for a long time.

· Due to its remarkable characteristics, the product is increasingly used in the market.

Company Features

· It is widely popular that Ruixing brand now leads the cnc metal parts manufacturer industry.

· Our technology plays an important role in the production of cnc metal parts manufacturer.

· Shenzhen Ruixing Precision MFG provides high-quality cnc metal parts manufacturer for a number of world-famous brands.

Application of the Product

The cnc metal parts manufacturer produced by Ruixing is of high quality and is widely used in the industry.

Ruixing has an excellent team consisting of R&D, production, operation and management. According to actual needs of different customers, we could provide customers with practical solutions.