Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

Cnc Machine Metal Parts RuiXing MFG - - Ruixing

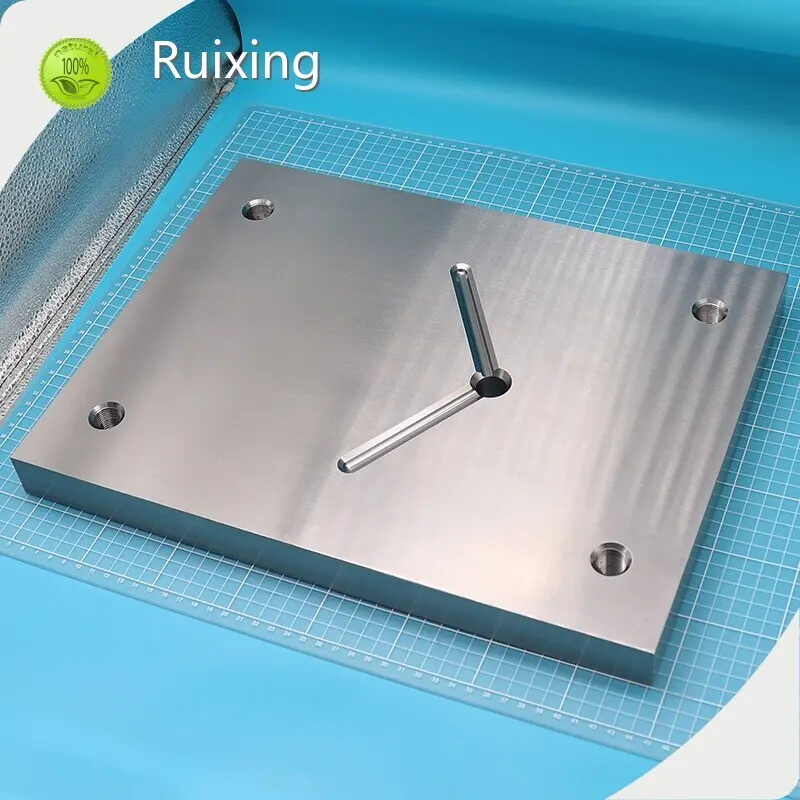

Product details of the cnc machine metal parts

Quick Detail

Ruixing cnc machine metal parts is designed to maintain a high-grade appearance. It is put on the market after strict quality inspection. The cnc machine metal parts produced by Ruixing is widely used in many industry sectors. This product provides maximum satisfaction by catering to the requirements of clients.

Product Information

Ruixing's cnc machine metal parts has been greatly improved in the following details.

Characteristic

1. Chemical Composition:

- Carbon (C): 0.38-0.43%

- Silicon (Si): 0.15-0.35%

- Manganese (Mn): 0.70-0.90%

- Phosphorus (P): ≤ 0.035%

- Sulfur (S): ≤ 0.040%

- Chromium (Cr): 0.70-0.90%

2. Mechanical Properties:

- Tensile Strength: 925-1020 MPa

- Yield Strength: 785 MPa (min)

- Elongation at Break: 13-17%

- Hardness (Brinell): 179-235 HB

3. Thermal Properties:

- Melting Point: 1460°C (2660°F)

- Specific Heat Capacity: 0.46 J/g-°C

4. Advantages:

- High Strength:

AISI 5140 steel exhibits excellent tensile strength and hardness, making it suitable for applications requiring robust mechanical properties.

- Wear Resistance:

With its chromium content, AISI 5140 steel offers good wear resistance, enhancing durability in demanding environments.

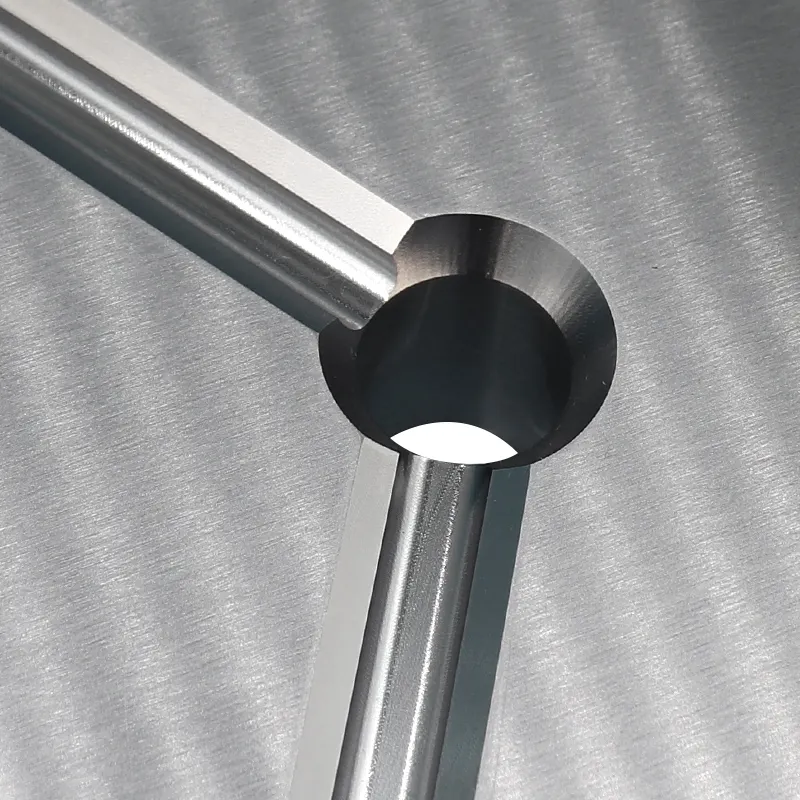

- Machinability:

The composition and microstructure of AISI 5140 steel facilitate ease of machining, allowing for efficient CNC precision milling operations.

5. Disadvantages:

- Limited Corrosion Resistance:

While AISI 5140 steel offers adequate corrosion resistance in certain environments, it may not be suitable for highly corrosive conditions without proper protection.

- Weldability Challenges:

Welding AISI 5140 steel requires preheating and post-weld heat treatment to prevent cracking and maintain mechanical properties, posing challenges in welding applications.

Application

1. Automotive Industry:

- Transmission Components:

AISI 5140 steel is used for manufacturing transmission gears, shafts, and other critical components due to its excellent strength, wear resistance, and machinability.

- Suspension System Parts:

CNC precision milling of AISI 5140 steel produces durable and reliable suspension system parts like control arms and linkages, ensuring superior performance and longevity.

2. Aerospace Sector:

- Landing Gear Components:

CNC-machined AISI 5140 steel parts are integral to landing gear assemblies, providing high strength and fatigue resistance to withstand the demanding conditions of flight operations.

- Engine Mounts:

Precision-milled AISI 5140 steel components play a crucial role in engine mount systems, offering robust support and vibration damping properties for aircraft engines.

3. Machinery Manufacturing:

- Industrial Gears:

AISI 5140 steel is widely utilized in CNC milling for producing industrial gears, offering excellent load-bearing capacity, toughness, and resistance to wear and deformation.

- Hydraulic Components:

CNC-machined AISI 5140 steel parts are essential in hydraulic systems, ensuring reliable performance under high pressure and dynamic operating conditions.

4. Renewable Energy:

- Wind Turbine Components:

CNC precision milling with AISI 5140 steel fabricates various wind turbine parts such as shafts, hubs, and gearboxes, delivering the durability and strength required for renewable energy generation.

FAQ

Company Introduction

Shenzhen Ruixing Precision MFG is a company. We are mainly engaged in the production, processing and sales of CNC Machining Services,Sheet Metal Fabrication. Our company persists in the concept of 'faithful management, continuous improvement', and the tenet of 'quality oriented, customer first'. Based on this, we seek to provide customers with all-round quality services while achieving considerable development. We look forward to working with all new and old customers to create brilliant future. In addition to the existing employees, our company also employs high-quality professional and technical research talents as our technical consultants to guarantee for our research and development and production of high-quality products. We have been engaged in the production and management of CNC Machining Services,Sheet Metal Fabrication for many years. For some problems encountered by customers in the procurement, we have the ability to provide customers with a practical and effective solution to help customers solve problems better.

Do not hesitate to contact us if you are interested in ourCNC Machining Services,Sheet Metal Fabrication.