Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

Precision CNC milling 304 stainless steel service

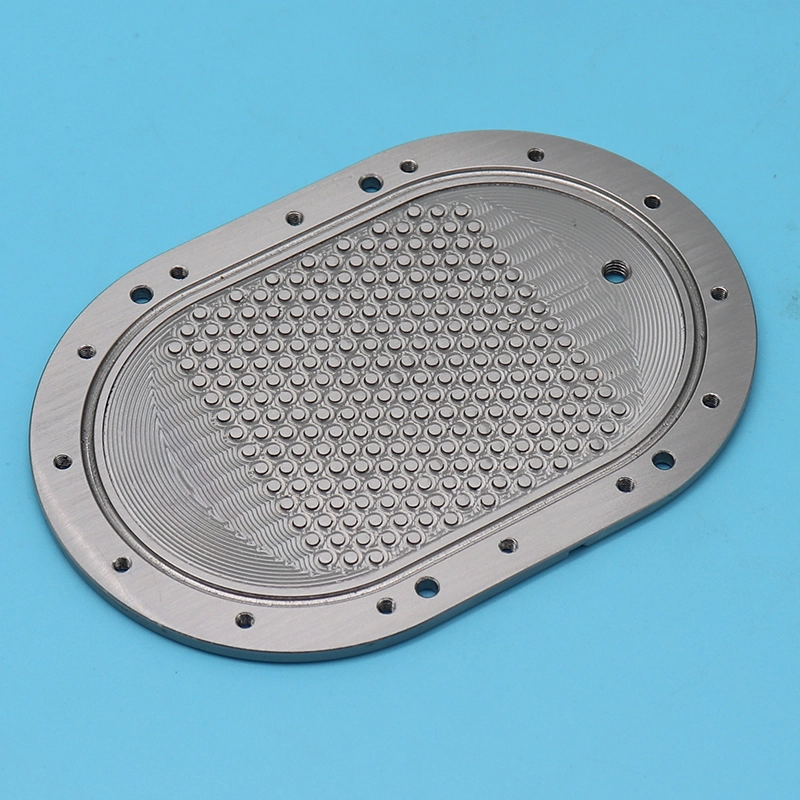

Welcome to our precision CNC milling 304 stainless steel service specializing in CNC machined metal and plastic components. With a focus on custom OEM solutions, we provide high-quality machining services tailored to your specific requirements.

With CNC milling, we offer versatility in part design, allowing for complex geometries and intricate features to be accurately machined. Whether you require prototypes or production runs, our CNC milling service delivers precise results, meeting your exact specifications.

Our commitment to quality extends to every stage of the machining process, from material selection to final inspection. We understand the importance of reliable components in your applications, and our stringent quality control measures ensure that each part meets the high standards.

From automotive to aerospace, medical devices to industrial equipment, our precision CNC milling service caters to diverse industries, providing custom 304 stainless steel parts that perform reliably in demanding environments.

Partner with us for your precision CNC milling needs, and experience the difference of tailored solutions and exceptional quality.

Characteristic

1. Dimensional Accuracy:

Precision CNC milling 304 stainless steel service ensures precise dimensional accuracy, meeting tight tolerances required for intricate component designs.

2. Surface Finish Control:

The process allows for controlled surface finishes, ranging from matte to glossy, providing aesthetic versatility to suit various applications.

3. Material Stability:

304 stainless steel offers excellent stability during CNC milling, minimizing the risk of warping or distortion, ensuring consistency in part dimensions.

4. Corrosion Resistance:

304 stainless steel exhibits high corrosion resistance, making it suitable for applications in corrosive environments, ensuring longevity and reliability.

5. Machinability:

Despite its robust nature, 304 stainless steel maintains good machinability during CNC milling, allowing for efficient production of complex parts.

6. Thermal Conductivity:

The material's thermal conductivity properties facilitate effective heat dissipation, making it suitable for components subjected to thermal stress.

Application

1. Automotive Sector: Engine Components

Precision CNC milling 304 stainless steel service is extensively used to manufacture critical engine components in the automotive sector. From cylinder heads to exhaust systems, 304 stainless steel parts ensure durability, corrosion resistance, and precise functionality.

2. Aerospace Industry: Structural Components

In aerospace applications, CNC-milled 304 stainless steel finds its place in the production of structural components. These parts provide the required strength and resistance to harsh environmental conditions, contributing to the safety and reliability of aircraft.

3. Medical Devices: Surgical Instruments

Precision is paramount in medical devices, and CNC-milled 304 stainless steel is employed in the production of surgical instruments. The material's biocompatibility, combined with accurate machining, ensures the quality and reliability of these critical medical tools.

4. Electronics: Connectors and Housings

The electronics industry benefits from CNC milling for the production of connectors and housings. 304 stainless steel provides the necessary conductivity, corrosion resistance, and structural integrity required for electronic components.

5. Industrial Machinery: Gear and Bearing Components

In industrial machinery, CNC-milled 304 stainless steel is used for manufacturing gear and bearing components. The material's strength and resistance properties contribute to the efficiency and longevity of these crucial parts.

6. Oil and Gas: Valve Components

The oil and gas sector relies on precision CNC milling for the production of valve components. 304 stainless steel's resistance to corrosion and harsh environmental conditions makes it an ideal choice for critical applications in this industry.

7. Renewable Energy: Wind Turbine Parts

In the renewable energy sector, CNC-milled 304 stainless steel is employed in the production of wind turbine parts. The material's durability and corrosion resistance ensure the longevity and reliability of these components in challenging environments.

FAQ