Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

Metal Cnc Parts ISO9001 - - Ruixing

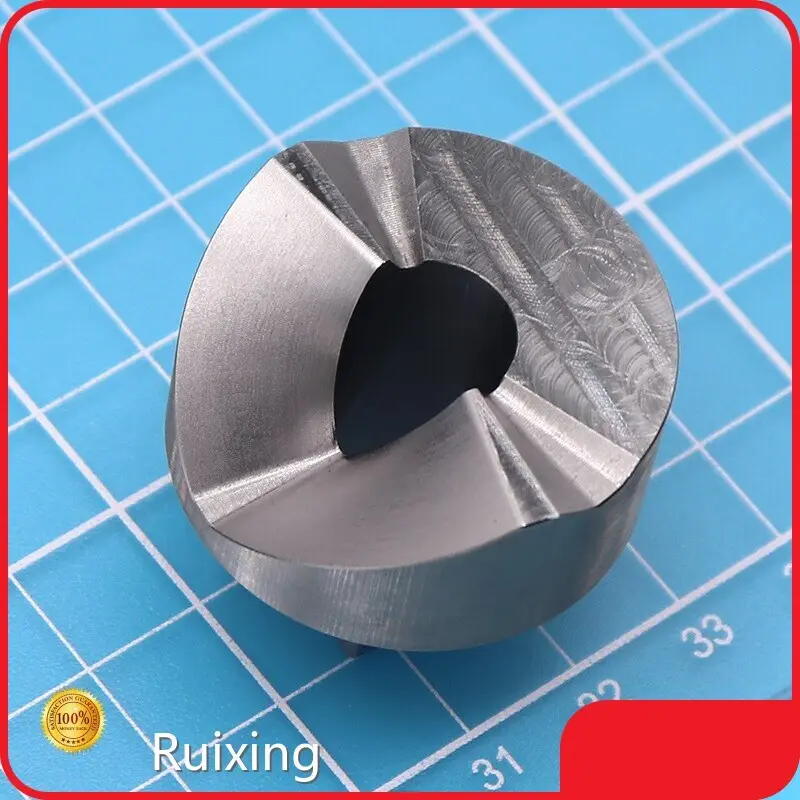

Product details of the metal cnc parts

Product Overview

We have been working to replace hazardous substances in Ruixing metal cnc parts. This product has excellent performance, durability and usability. The metal cnc parts produced by Ruixing has a wide range of applications. Shenzhen Ruixing Precision MFG's strict quality control system provides guarantee for ensuring international product quality standards.

Product Description

Compared with peer products, our metal cnc parts has more obvious advantages and they are reflected in the following aspects.

Characteristic

1. Chemical Composition:

- GCr15 / AISI 52100 / ASTM A295 / 100Cr6 materials have a chemical composition primarily consisting of:

- Carbon (C): 0.95-1.05%

- Chromium (Cr): 1.30-1.60%

- Manganese (Mn): 0.25-0.45%

- Silicon (Si): 0.15-0.35%

- Phosphorus (P): ≤0.025%

- Sulfur (S): ≤0.025%

2. Hardness:

- These materials exhibit high hardness levels, typically ranging from 60 to 66 HRC (Rockwell Hardness Scale), making them suitable for applications requiring wear resistance and toughness.

3. Tensile Strength:

- The tensile strength of GCr15 / AISI 52100 / ASTM A295 / 100Cr6 materials ranges from 600 to 850 MPa, providing excellent strength and load-bearing capabilities.

4. Fatigue Strength:

- These materials demonstrate good fatigue strength, allowing them to withstand repeated loading cycles without failure, making them suitable for applications involving dynamic stresses.

5. Corrosion Resistance:

- While GCr15 / AISI 52100 / ASTM A295 / 100Cr6 materials exhibit moderate corrosion resistance, they may require additional surface treatments or coatings to enhance protection against corrosion in harsh environments.

6. Wear Resistance:

- One of the key characteristics of these materials is their exceptional wear resistance, attributed to the high carbon and chromium content. This property makes them ideal for applications involving sliding or rolling contact, such as bearings and gears.

7. Machinability:

- GCr15 / AISI 52100 / ASTM A295 / 100Cr6 materials can be machined to precise dimensions with custom CNC processes. However, their high hardness may pose challenges during machining, requiring appropriate cutting tools and techniques.

8. Heat Treatment:

- Heat treatment, particularly quenching and tempering, is essential to achieve the desired mechanical properties in GCr15 / AISI 52100 / ASTM A295 / 100Cr6 materials. Proper heat treatment enhances hardness, strength, and toughness, ensuring optimal performance in various applications.

Product Advantages

1. Automotive Customizations:

Within the automotive industry, our precision machined AISI 52100 parts find their niche in specialized applications such as high-performance racing engines. From camshafts to valve train components, our custom CNC machining ensures precise specifications and durability, contributing to enhanced engine performance and reliability.

2. Oil and Gas Exploration:

In the oil and gas sector, our AISI 52100 parts are crucial for downhole drilling tools, including drill bits and bearings. The superior hardness and wear resistance of these parts withstand harsh drilling conditions, ensuring prolonged equipment life and efficient extraction operations.

3. Renewable Energy Solutions:

In the renewable energy industry, our precision machined AISI 52100 parts play a vital role in wind turbine gearbox assemblies. From planetary gears to main shaft bearings, our custom CNC machining delivers components that withstand high torque loads and harsh environmental conditions, contributing to reliable wind energy generation.

4. Medical Device Manufacturing:

Within the medical device manufacturing sector, our AISI 52100 parts are utilized in precision surgical instruments and implantable medical devices. The biocompatibility and corrosion resistance of these parts ensure safe and reliable performance in critical healthcare applications, such as orthopedic surgery and cardiovascular interventions.

5. Aerospace Innovations:

Our precision machined AISI 52100 parts play a pivotal role in the aerospace industry, particularly in the manufacturing of aircraft landing gear components. From landing gear struts to wheel bearings, our custom CNC machining ensures the highest standards of quality and reliability, meeting the stringent requirements of aerospace engineering.

6. Marine Engineering:

Within the marine engineering sector, our AISI 52100 parts are utilized in marine propulsion systems, including propeller shafts and bearings. The corrosion-resistant properties of these parts make them ideal for marine applications, ensuring reliable performance and longevity in challenging maritime environments.

7. High-Performance Sports Equipment:

In the realm of high-performance sports equipment, our precision machined AISI 52100 parts contribute to the performance and durability of sporting goods such as bicycle components. From wheel hubs to bottom brackets, our custom CNC machining delivers lightweight and high-strength parts that withstand the rigors of competitive cycling.

8. Electronics Manufacturing:

Within the electronics manufacturing industry, our AISI 52100 parts are essential for precision electromechanical components used in semiconductor manufacturing equipment. From wafer handling systems to precision actuators, our custom CNC machining ensures precise specifications and reliable performance, supporting the production of advanced semiconductor devices.

FAQ

Company Information

Shenzhen Ruixing Precision MFG, situated in shen zhen, is a enterprise. We are devoted to the production, processing, and sales of CNC Machining Services,Sheet Metal Fabrication. Ruixing has excellent customer service management team and professional customer service personnel. We can provide comprehensive, thoughtful, and timely services for customers. We are committed to guaranteeing the product quality and after-sales service. Welcome to contact us for cooperation!