Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

Cnc Machining Parts Supplier Price List

Characteristic

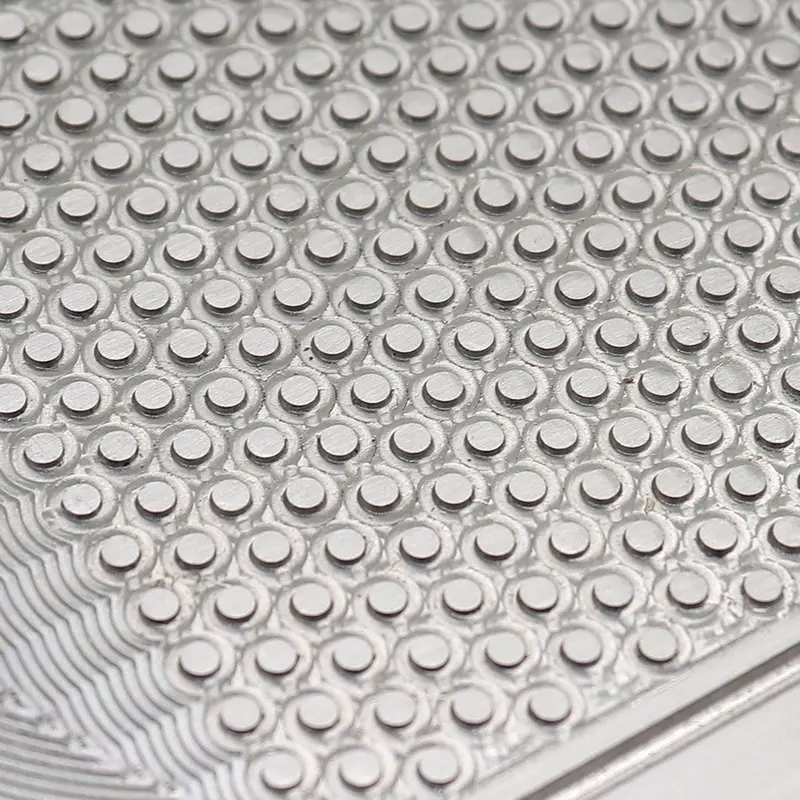

1. Dimensional Accuracy:

Precision CNC milling 304 stainless steel service ensures precise dimensional accuracy, meeting tight tolerances required for intricate component designs.

2. Surface Finish Control:

The process allows for controlled surface finishes, ranging from matte to glossy, providing aesthetic versatility to suit various applications.

3. Material Stability:

304 stainless steel offers excellent stability during CNC milling, minimizing the risk of warping or distortion, ensuring consistency in part dimensions.

4. Corrosion Resistance:

304 stainless steel exhibits high corrosion resistance, making it suitable for applications in corrosive environments, ensuring longevity and reliability.

5. Machinability:

Despite its robust nature, 304 stainless steel maintains good machinability during CNC milling, allowing for efficient production of complex parts.

6. Thermal Conductivity:

The material's thermal conductivity properties facilitate effective heat dissipation, making it suitable for components subjected to thermal stress.

Application

1. Automotive Sector: Engine Components

Precision CNC milling 304 stainless steel service is extensively used to manufacture critical engine components in the automotive sector. From cylinder heads to exhaust systems, 304 stainless steel parts ensure durability, corrosion resistance, and precise functionality.

2. Aerospace Industry: Structural Components

In aerospace applications, CNC-milled 304 stainless steel finds its place in the production of structural components. These parts provide the required strength and resistance to harsh environmental conditions, contributing to the safety and reliability of aircraft.

3. Medical Devices: Surgical Instruments

Precision is paramount in medical devices, and CNC-milled 304 stainless steel is employed in the production of surgical instruments. The material's biocompatibility, combined with accurate machining, ensures the quality and reliability of these critical medical tools.

4. Electronics: Connectors and Housings

The electronics industry benefits from CNC milling for the production of connectors and housings. 304 stainless steel provides the necessary conductivity, corrosion resistance, and structural integrity required for electronic components.

5. Industrial Machinery: Gear and Bearing Components

In industrial machinery, CNC-milled 304 stainless steel is used for manufacturing gear and bearing components. The material's strength and resistance properties contribute to the efficiency and longevity of these crucial parts.

6. Oil and Gas: Valve Components

The oil and gas sector relies on precision CNC milling for the production of valve components. 304 stainless steel's resistance to corrosion and harsh environmental conditions makes it an ideal choice for critical applications in this industry.

7. Renewable Energy: Wind Turbine Parts

In the renewable energy sector, CNC-milled 304 stainless steel is employed in the production of wind turbine parts. The material's durability and corrosion resistance ensure the longevity and reliability of these components in challenging environments.

FAQ

Company Advantages

· The offered Ruixing cnc machining parts supplier is designed by a team of experienced professionals.

· Comprehensive quality control is carried out to ensure the product meets with all related quality standards.

· Shenzhen Ruixing Precision MFG has the most knowledgeable experts and reliable, easy-to-use products.

Company Features

· Shenzhen Ruixing Precision MFG pays attention to the cnc machining parts supplier and is influential in the business.

· Ruixing conducts technological innovation and promotes cnc machining parts supplier research.

· Our success is built on the trust we earned from clients. We work shoulder-to-shoulder with our clients to solve complex challenges in ways that minimize business risk and maximize opportunity.

Application of the Product

The cnc machining parts supplier developed and produced by our company is widely applied to many industries and fields, and it can fully meet the diversified needs of customers.

Ruixing is dedicated to solving your problems and providing you with one-stop and comprehensive solutions.