Ruixing MFG - Custom CNC Machined Parts Manufacturer & Supplier For 20 Years

Stainless Steel Machining Parts ISO9001 Gallery of CNC Parts Wholesale - Ruixing

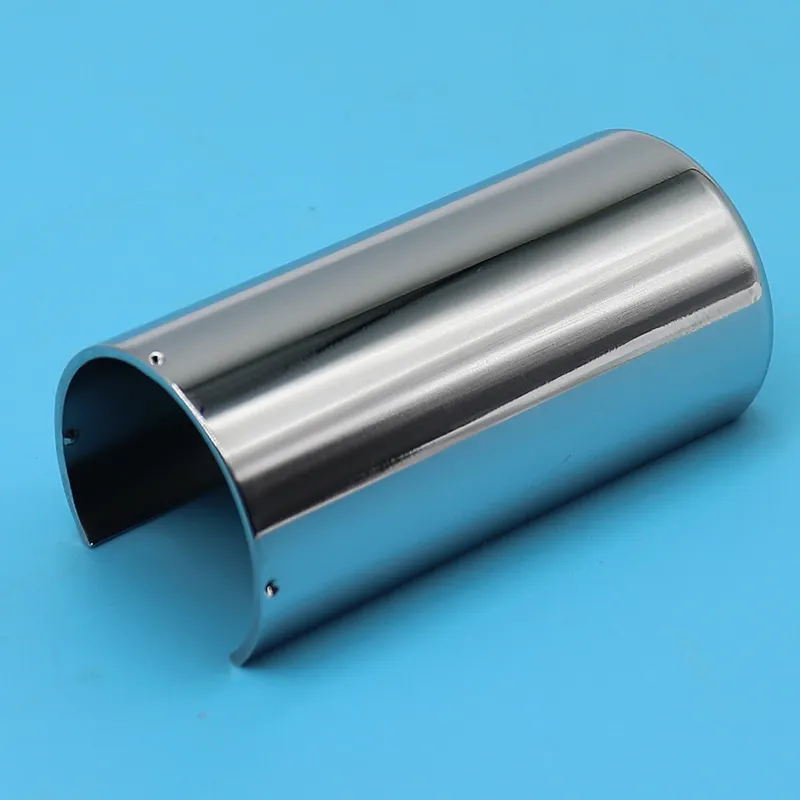

Product details of the stainless steel machining parts

Quick Overview

stainless steel machining parts's performance is popularly accepted in the country and abroad. The product is able to meet the high quality requirements of many varieties of production. By offering reliable installation service, Ruixing has gained more trustworthy clients.

Product Introduction

We value the quality of our products. And we strive for perfection in every detail of products. In this way, we guarantee the fine quality of our products.

Characteristics:

1. Chemical Composition:

- Chromium: 16-18%

- Nickel: 10-14%

- Molybdenum: 2-3%

- Iron: Balance

2. Corrosion Resistance:

- Exceptional resistance to corrosion in various environments, especially in acidic and chloride-rich conditions.

3. Temperature Resistance:

- Maintains strength and corrosion resistance at elevated temperatures up to 1600°F (870°C).

4. Tensile Strength:

- High tensile strength ranging between 515 and 620 MPa.

5. Yield Strength:

- Yield strength of 0.2% offset is minimum 205 MPa.

6. Density:

- Density is approximately 8 g/cm³, contributing to its robustness.

Advantages:

1. Corrosion Resistance:

- Ideal for applications in corrosive environments, such as marine and chemical industries.

2. Temperature Stability:

- Maintains structural integrity at high temperatures, suitable for elevated temperature applications.

3. Strength and Durability:

- High tensile and yield strength contribute to the material's overall durability.

Disadvantages:

1. Cost:

- Relatively higher cost compared to other stainless steel grades.

2. Machinability:

- Has reduced machinability compared to other austenitic stainless steels.

Application

1. Automotive Industry:

Exhaust Manifold Components

Precision CNC machining plays a vital role in crafting exhaust manifold components from 316 stainless steel with chrome plating. These parts endure high temperatures, corrosive elements, and require exacting precision for optimal engine performance.

2. Medical Equipment Manufacturing:

Surgical Instruments

CNC-machined surgical instruments benefit from 316 stainless steel's biocompatibility and the protective layer of chrome plating. These precision components ensure the highest standards of hygiene, durability, and functionality.

3. Aerospace Engineering:

Aircraft Landing Gear Components

Components like landing gear parts demand the strength of 316 stainless steel and the protective properties of chrome plating. CNC machining guarantees the precision necessary for critical aerospace applications, ensuring safety and reliability.

4. Electronic Devices Production:

Connector Components

CNC-machined connector components made from 316 stainless steel with chrome plating offer optimal conductivity and protection against environmental factors. These precision parts are essential for electronic devices, ensuring reliable connectivity.

5. Marine Equipment Fabrication:

Propeller Shaft Components

CNC machining in the fabrication of propeller shaft components involves 316 stainless steel with chrome plating, providing corrosion resistance in harsh marine environments. Precision is paramount to guarantee the efficiency of these crucial marine elements.

6. General Engineering Applications:

Pump Housing Components

Pump housing components, crucial in various engineering applications, benefit from CNC machining in 316 stainless steel with chrome plating. The precision ensures the integrity and longevity of these components in diverse industrial settings.

Chrome Plating:

1. Process:

- Chrome plating, also known as chromium electroplating, involves depositing a thin layer of chromium onto a metal surface through electrochemical processes.

2. Materials:

- The process commonly involves the use of hexavalent chromium baths, ensuring the formation of a protective and lustrous chromium layer.

3. Purpose:

- Chrome plating serves various purposes, including corrosion resistance, enhanced hardness, and aesthetic improvement.

4. Application:

- Commonly applied to components in the automotive, aerospace, and machining industries to enhance durability and mitigate corrosion.

Advantages of Chrome Plating:

1. Corrosion Resistance:

- Chrome plating provides an effective barrier against corrosion, extending the lifespan of components.

2. Hardness Enhancement:

- The process contributes to increased surface hardness, improving resistance to wear and abrasion.

3. Aesthetic Improvement:

- Chrome plating imparts a shiny and visually appealing surface finish, enhancing the overall appearance of components.

Applications in CNC Machining:

1. Tooling and Dies:

- Chrome-plated surfaces in tooling and dies reduce friction, improve release characteristics, and enhance the longevity of these critical components.

2. Aesthetic Components:

- Chrome plating is often applied to components with a focus on aesthetics, providing a polished and refined appearance to machined parts.

FAQ

Company Information

Shenzhen Ruixing Precision MFG is a company specializing in CNC Machining Services,Sheet Metal Fabrication management, located in shen zhen. Consistent with the philosophy of 'quality for survival, reputation for development', we are willing to cooperate with all sectors of society for common advancement and win-win situation. Our company has cultivated a group of high-quality talents to form an excellent team. They are highly educated, experienced and professional. Ruixing has many years of industrial experience and great production capability. We are able to provide customers with quality and efficient one-stop solutions according to different needs of customers.

Our products are of guaranteed quality and tight package. Welcome customers with needs to contact us!